1

UE SYSTEMS INC.

THE ULTRAPROBE 15,000 MANUAL

2

TABLE OF CONTENTS

OVERVIEW

COMPONENTS

ACCESSORIES

USER INSTRUCTIONS

Introduction

Ultraprobe 15,000 Kit

Plug-In Modules

Scanning Module

Contact Module

LRM – Long Range Module

RAM/RAS-MT REMOTE MAGNETIC TRANSDUCER

Pistol Grip Housing

Key Features

On/Off/Suspend button

Turn Off

Suspend

SD Card

Trigger Switch

Touch Screen Display

Spectral Analysis Screen (FFT)

Camera

IR Thermometer

Laser Pointer

Battery

Test Module Receptacle

Standard Accessories

Headset

WTG-1 Warble Tone Generator

Rubber Focusing Probe

Stethoscope Extension Kit

Battery

BCH-15 Battery Charger

Battery Charger Pod

5

5

5

6

6

6

6

7

7

7

7

7

7

7

8

8

8

8

9

9

9

9

9

10

10

10

10

10

10

10

11

11

3

DISPLAY ICONS

SETTING UP THE ULTRAPROBE 15,000

Optional Accessories

CFM-10 – Close Focus Scanning Module

UWC-10 – Ultrasonic Waveform Concentrator

DHC-2 Headphones

TFSM - Telescoping Flexible Scanning Module

TFCM - Telescoping Stethoscope Module

UFMTG-1991 – Multi-directional WTG

BCH-WTG – WTG Charger

HTS-10 – Holster Set

Turn on the Ultraprobe 15,000

Home Screen

Main Screen (dB)

Setup Screen

dB/Temp

Route

Remove SD Card

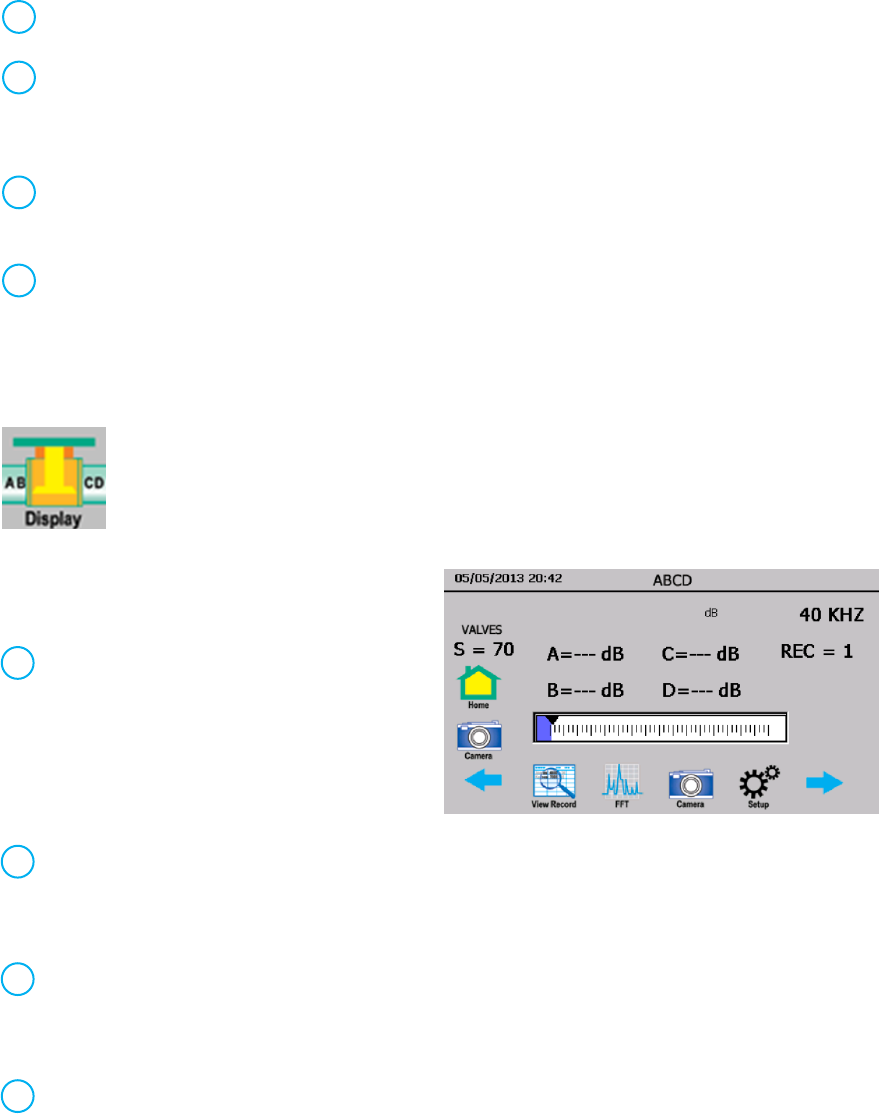

Valve (ABCD) Screen

Setup Mode

Preferences

Info

Reset

Upgrade

Applications

Exit

Viewing and Selecting Icons

Using Screens

Using Main Screen

Using dB/Temp Screen

Using Temp & Emissivity Screen

Using Valve/Steam Screen

Using Spectra (FFT) Screens

Storing a Record

Recording a Sound

Entering Test Data

View Record

Viewing, Sorting a Route

11

11

11

11

11

12

12

12

12

13

14

14

14

14

14

14

14

14

14

15

15

17

17

17

18

18

18

19

19

20

20

21

22

23

23

23

24

24

4

USERS INSTRUCTIONS

UP10,000 INSTRUMENT SPECIFICATIONS

SETTING THE COMBINATION LOCK

APPENDEX A - SENSITIVITY CALIBRATION

Camera

Strobe

Bluetooth

Trigger Switch

Quick Change Battery

Wrist Strap

Headset Jack

Recharge Jack

Charging Pod

Trisonic- Scanning Module

Method of Airborne Detection

Headset

Rubber Focusing Probe

Long Range Module

Stethoscope Module

Stethoscope Extension Kit

RAM-MT Magnetic Transducer

Charging The UP15000

Warble Tone Generator

Charging The Warble Tone Generator

Helpful Hints

Auto Shutdown Battery Feature

25

25

26

26

26

26

27

27

27

28

28

28

28

28

29

29

29

30

30

30

31

31

31

32

34

35

5

OVERVIEW

INTRODUCTION

The Ultraprobe 15,000 is a versatile instrument with many features that will make for easy, fast

and accurate inspections. As with any new instrument, it is important to review this

manual before using the it for inspections.

ULTRAPROBE® 15,000 KIT

Pistol-Grip Housing

WTG-1 Warble

Tone

RAS/RAM - Magnetic

Transducer & Cable

Battery & Pod

Headphones

Stetoscope Module

0

Rubber Focusing Probe

Long Range Module

with Laser Sight

Stethoscope

Extension Kit

Battery Recharger

6

COMPONENTS

PLUG-IN MODULES

TRISONIC

TM

SCANNING MODULE. This module is

utilized to receive air-borne ultrasound such as the ultrasounds

emitted by pressure/vacuum leaks and electrical discharges.

There are four prongs at the rear of the module. For placement,

align the prongs with the four corresponding jacks in the front

end of the pistol housing and plug in. The TrisonicTM Scanning

Module has a phased array of three piezoelectric transducers to

pick up the airborne ultrasound. This phased array focuses the

ultrasound on one "hot spot" for directionality and effectively

intensifies the signal so that minute ultrasonic emissions can be

detected.

STETHOSCOPE

(CONTACT) MODULE.

This is the module with the

metal rod. This rod is

utilized as a "waveguide" in

that it is sensitive to

ultrasound that is generated

internally such as within a

pipe, bearing housing or steam trap. Once stimulated by ultrasound, it transfers the

signal to a piezoelectric transducer located directly in the module housing.

The module is shielded to provide protection from stray RF waves that can affect

electronic receiving and measurement. It is equipped with low noise amplification to

allow for a clear, intelligible signal to be received and interpreted. For placement align

the four prongs on the back with the corresponding receptacles in the front of the

pistol and plug in.

7

LRM (LONG RANGE MODULE). A cone shaped

scanning module that increases the detection

distance above standard scanning modules. The

LRM-15 is ideal for high voltage inspection and

for locating leaks at great distances.

RMT REMOTE MAGNETIC TRANSDUCER. The RMT

is a magnetically mountable contact probe with cable.

The probe is applied to a test surface and the RAM

(Remote Access Module) is plugged into the front end of

the Ultraprobe.

PISTOL-GRIP HOUSING

KEY FEATURES. The pistol grip housing contains operational

features such as: On/Off button, Trigger Switch, Touch Screen,

camera with flash, Infrared Thermometer, Laser pointer,

Battery, and Test Module Receptacle.

ON/OFF BUTTON. This is located on the back of the

instrument, under the Display Panel. Press it firmly to turn the

instrument ON.

NOTE:

Be sure the SD card is inserted in the Ultraprobe

15,000 before turning on.

To turn the instrument off:

Press the On/Off button

Touch the Off Box on the display screen

To place the instrument in suspend. In place of turning the instrument on and off in

between short intervals of use, or to extend the use time on a battery (normally 4 hours of

continuous use after a complete charge), put the instrument on SUSPEND. To do so:

Press the On/Off button

Touch the SUSPEND box on the display screen

To return to operation mode (cancel the SUSPEND mode):

Touch the display screen OR pull the trigger, and display will re-open.

8

SD CARD AND SD CARD SLOT. The SD card is used to store the

inspection data and sound files. It will hold the test information for

transfer to a computer that has Ultratrend DMS V 5.0 or higher

installed.

To remove the SD card. When removing the SD Card while the

instrument is on, open the Home Screen and touch this icon. A prompt

will appear when it is safe to turn the instrument off.

NOTE:

Be sure the SD card is inserted in the Ultraprobe 15,000 before

turning it on. ALWAYS touch the “REMOVE SD CARD” icon before

removing the SD card.

TRIGGER SWITCH. The trigger has multiple functions.

While performing a test pull the trigger in. Holding the trigger

in allows the instrument to actively scan the subject test

equipment.

To hold a reading for storage or review, release the trigger.

The instrument will no longer actively adjust to changes in

data being received.

The trigger is also used to turn on the laser pointer or the IR Thermometer when

these features have been selected in the “Set Up Menu”.

TOUCH SCREEN DISPLAY. All inspection

functions can be controlled by just touching an icon,

arrow or data box.

SPECTRAL ANALYSIS SCREEN. Select FFT

(Spectra) display, Time Series display or dual display:

Record and Play back sounds.

0

0

0

0

9

CAMERA. The camera can be used to capture images

of test points or items of interest that can be added into

DMS reports.

INFRARED THERMOMETER. This non-contact thermometer will measure the

temperature of a test point. It can be used in the Temp screen and in the dB/Temp

screen.

LASER POINTER. This non-contact thermometer will measure the temperature of a

test point. It can be used in the Temp screen and in the dB/Temp screen.

To activate the laser:

Enter the setup mode.

Select the “Oper” tab and look for Trigger Features. Touch the Trigger Features

box.

Using the arrows, move up or down until Trig & Laser ON/OFF is shown.

Touch the box to select and exit.

BATTERY. Slide the battery into the handle until it “Clicks”

in securely.

TEST MODULE RECEPTACLE

0

0

0

0

0

10

ACCESSORIES

STANDARD ACCESSORIES

HEADSET. This heavy-duty headset is designed for use

with or without a hardhat and can block out intense

sounds often found in industrial environments so that the

user may easily hear the sounds received by the

ULTRAPROBE. In fact, these headphones provide over 23

dB of low frequency noise attenuation.

WTG-1 WARBLE TONE GENERATOR. The WTG-1

Tone Generator is an ultrasound transmitter used to

validate the sensitivity of an Ultraprobe before and at

times after an inspection. For details on the Sensitivity

Validation test, see Appendix A: Sensitivity Validation

Test. The Warble Tone generator may also be used for

specialized tests such as when it is difficult to produce

pressure or draw a vacuum, will flood an area with

ultrasound which will flow through a (usually) large leak

area. By scanning

with the TrisonicTM Scanning Module, empty containers such as, bulkheads or

hatches can be instantly checked for leakage.

RUBBER FOCUSING PROBE. The Rubber Focusing Probe is a cone shaped rubber

shield. It is used to block out stray ultrasound and to assist in narrowing the field of

reception of the “Trisonic" Scanning Module.

STETHOSCOPE EXTENSION KIT. This consists of three metal rods that will enable

a user to reach up to 31 additional inches (78.7 cm) with the Stethoscope Module.

BATTERY (2). This Ultraprobe 15,000 uses a lithium ion battery. A full charge will

take about 4 hours; however, it is possible to charge the unit at any time for short

intervals or for a longer period. If it is kept on charge over 4 hours, there will be no

harm to the battery.

11

NOTE:

When the effective battery charge is used up the instrument shuts down and

a message to recharge the battery will be displayed in the display panel

.

BCH-10 BATTERY CHARGER. This is the battery charger for the UP15,000. It

works with both 120 VAC, 60 Hertz and 240 VAC, 50 Hertz and comes with multiple

plug adaptors for different countries. The charging time is about 4 hours. There are

two plugs: Black for the main pistol housing and Yellow for the WTG-1 Tone

Generator.

UE-BATTERY CHARGER POD. This is a Battery Recharge Pod docking station for

charging Ultraprobe Batteries (Lithium Ion only). This pod will charge the standard

batteries that come with the Ultraprobe 15,000 while removed from the metered

pistol housing.

OPTIONAL ACCESSORIES

CFM-15. The “Close Focus” scanning module is

used for close proximity, low level leak detection in

pressure and vacuum systems.

UWC-15.

The UWC-15, Ultrasonic Waveform

Concentrator, substantially increases the detection

distance. The UWC-15 is great for corona, tracking and

arc detection at safe distances. Includes carrying case.

DHC-2.

Headphone is for Standard Applications

that do not require the use of a hard hat.

TFSM. Telescoping Flexible Scanning Module.

A flexible scanning probe that is bent to

accommodate odd scanning angles. The

telescoping action helps scan hard to reach

areas.

12

TFCM: Telescoping Stethoscope (Contact) Module. A contact probe for

structure borne inspection that can be extended for hard to reach areas.

UFMTG-1991. The UFMTG 1991 is a multi-directional warble

tone generator. It has a high-power output with a circular

transmission pattern of 360 degrees.

BCH-WTG. Optional 220 VAC @ 50 Hz chargers for all Warble Tone Generators. The

line input is 220 VAC @ 50Hz and the charging time is about 8 hours.

HTS-15. Holster set for the UP15,000.

13

DISPLAY ICONS

The main default screen

Main Screen displays dB

Display for dB and

temperature

Turns off/on Temperature

sensing

Spectral Analysis screen &

function

Set up instrument functions

Valve/Steam test display

Temperature display (no dB)

Opens Camera for photos

Use to View image and take

the photo

View uploaded route

Adjust Emissivity

View a specific historical

record

Input additional test data to

record

Store test data

Exit screen

Strobe

Remove SD Card

Bluetooth

14

SETTING UP THE ULTRAPROBE 15,000

TO TURN ON THE ULTRAPROBE 15,000

Press and then release the ON/OFF button as shown.

NOTE:

Be sure the SD card is inserted in the Ultraprobe

15,000 before turning it on. ALWAYS touch the “REMOVE

SD CARD” icon before removing the SD card.

HOME SCREEN

The Home Screen will display the Icons for the operation of the Ultraprobe

15,000. To select an operating screen, enter the Home Screen.

The icons in the home screen are:

NOTE:

To change from one operating screen (such as main, dB/Temp or Valve) to

another, return to the Home Screen.

dB (Main Screen)

This will display the test

decibel and the test

frequency

Setup: This Icon will

enter the setup screen

where the user can

configure the

instrument to meet

plant specific test

requirements.

dB/Temperature:

This test screen displays

decibel, frequency and

temperature.

Route: View the test route.

The route is displayed in

sequential order. Each record

can be viewed by selecting

(touching) the test number.

Remove SD Card: ALWAYS

(touch) this icon BEFORE

removing the SD Card.

ABCD (Valve Test Screen)

This screen will only be

displayed if the Valve or steam

been selected in

Setup/Applications. It will

display the dB data or

(A,B,C,D) test points and the

frequency.

15

SET UP MODES & FEATURES

Before using the instrument, become familiar with the various features and

modes of operation. The user can customize the instrument to meet plant

specific inspection demands. This is accomplished in the SETUP Mode.

To enter the set up mode:

Turn the instrument on.

Locate the Setup icon on the Home Screen.

Touch the Icon to enter the Setup mode.

NOTE:

To select or change a setting; touch the selection box or circle on the screen. In

some instances, it will be necessary to use the UP/DOWN arrows on the right side of the

screen to display choices.

Setup Icons are as follows:

NOTE:

When changing preferences or settings, touch the “OK” icon to save the changes.

Touch “Exit” to exit without saving changes.

PREFERENCES

Under “Preferences”, are the following sub fields:

a. Inspector ID: There are three empty fields that can be used to identify the

inspector.

b. Bluetooth: There are two options; “Enable” or “Disable”. This option allows for

connection of the audio feed to be connected to a Bluetooth headphone or earbuds.

If this is enabled, a Bluetooth icon will appear in the Setup screen.

16

c. Module type: This field allows the inspector to choose the module to be used in the

inspection. (Ex: SCM, LRM etc.)

NOTE:

Changing module type in this section, does NOT change the frequency

settings.

d. Disp (Display) Response: There are three options, the inspector can control the

speed at which the bar graph moves in relation to the meter responds to reflect a dB

level. There are three choices: Slow, Medium, Fast. The instrument defaults to Slow.

e. Triggr (Trigger) Features: There are two options: “Laser on” and “Laser Off”. The

Laser can be used for long distance inspection.

f. Alarm Enable: There are two options: “Enable” and “Disable”. Enabling this feature

will have the instrument alert the user if the monitored asset has moved into an

alarm state. This will present itself my coloring the dB reading red.

g. Alarm Rec (Record) Time: There are four options: The selection will include a

time value of from 5 seconds up to 30 seconds. The user may also select MANUAL.

When MANUAL is selected, press the REC (recording) box in the Spectral Screen. To

stop recording, Press STOP.

h. Headphone Vol (Volume): There may be situations in which the sound level in the

headphones is uncomfortably high and the sensitivity level must remain in a high

level. To make this comfortable for the user, the volume of the headphones can be

adjusted for 100% of volume to as low as 0% of volume.

i. Turn Off Time: The Turn-off time can be set to 5, 10 or 15 minutes. Or it can be

disabled. In disable, when the instrument is turned on, it will stay on until either it is

turned off, set in suspend or the battery charge is depleted.

j. Frequency Adjust: An inspector might want to be sure the frequency is not

changed during a route. To lock the frequency, select No, to enable frequency

tuning, select Yes.

k. Instrument Setup: The factory default is Manual. All adjustments are made by the

inspector as he/she goes through the route. The Automatic setting is used after the

initial baseline data has been uploaded to the Ultraprobe 15,000. In the Automatic

setting, the instrument will move sequentially from one test point to the next, and

set itself for the original baseline setup, which will include the Frequency and

Sensitivity for that point. For example, if the operator is testing bearings, the

instrument will move from test point 1 to test point two and the if the baseline data

was set at a sensitivity level of 43 with a frequency of 30 kHz, the instrument will

automatically set for these parameters.

l. Units: Set measuring units for Standard or Metric.

17

m. Frequency Def (Default): The default frequency from the factory is 40 kHz. If the

Ultraprobe is to be used consistently at another frequency, set the default to that

frequency. Every time the instrument is turned on, it will default to that selected

frequency. For example, if most of the inspections are to be mechanical, the user

might set the default frequency to 30 kHz.

n. Sensitivity Def (Default): The user can select a sensitivity value so that every

time the instrument is turned on for testing, that value will be the starting “high”

level. For example, the default factory Sensitivity value is 70. In some routes, this will

be too high and to save time the inspector will set to a lower value for a starting

point on that route.

INFO

Under “Info”, are the following sub fields:

a. Show Versions: This show the software version that is on-board the UP15000.

b. Set Date/time: Set the time and date as appropriate for a specific area in which

the instrument is used.

c. Calibration Due: This is set at the factory and reset every time the Ultraprobe is

sent back after calibration.

RESET

Under “Reset”, are the following sub fields:

a. Restore Lists: Options are “Yes” or “No”. All test information is set as a list in

Ultratrend DMS, the standard operating software that accompanies the Ultraprobe. If

list identification letters have been changed in Ultratrend DMS, they will be entered

into the Ultraprobe. Restore lists will reset the Ultraprobe back to the original lists as

set at the factory.

b. Deflt (Default) Settings: When Yes is selected, the instrument settings will default

back to the original settings as it came from the factory.

UPGRADE

Under “Upgrade”, are the following sub fields:

a. Upgrade Progm (Program): The options are “Yes” or “No”. When there is an

upgrade to the Ultraprobe 15,000 it may be downloaded off the web onto the SD

card. Insert the SD card with the upgrade and use Upgrade Program.

18

b. Upgrade Lang (Language): The options are “Yes” or “No”. Contact UE Systems

for assistance.

APPLICATIONS

Each application has unique data. When an application is selected the instrument will

automatically set up specific fields that are unique to that application.

The specific applications are:

a. Generic

b. Valves

c. Bearing

d. Electrical

e. Steam

f. Leak

There is one other selection on the Applications page:

g. Fields: These are test information fields that can accompany test results. Select the

specific fields for an application and then touch OK to set. While performing tests on

a route after exiting setup, the operator can select the “Input Data” Icon on the main

data collection page to select any of the following (if they have been selected).

Test Results, Temperature, Application, Pressure, Pipe Diameter, Type, etc.

EXIT

Touch this icon to return to the “Home” page.

VIEWING AND SELECTING ICONS

Icons may be viewed on any of the following display screens: Main, dB and Temperature,

Valve and Temperature.

Only two icons at a time may be shown continuously.

To view icons: touch the bottom of the screen.

To view more icons, use the “left/right” arrows to move icons on and off the screen

To select an icon for continuous display and easy access on the screen:

Touch the bottom of the screen to display the icons

Use the left/right arrows until the icon needed is displayed

Touch the icon and slide it up to the middle of the left side of the display screen

19

USING THE SCREENS

To use any of the screens:

Turn on the Ultraprobe by pressing the ON button

When the Home screen opens, select an Icon

To use an operational screen such as “Main”, “dB/Temp”, “Temp”, or Valve.

Pull the trigger in and begin the inspection. If no or very little ultrasound is present, or

if the sensitivity value is too high for the test area, the dB will not show on the screen.

3 Dashed (---) lines will show. Adjust the “S” (Sensitivity value) by touching the

Sensitivity box and then use the Up/DOWN arrows to move the S value up or down as

needed.

To freeze a reading for saving or observation, release the trigger.

MAIN

This screen will display the Record number, Decibel, Frequency, Sensitivity

Level and an Intensity Level box. The Intensity Level box also acts as the

Sensitivity Control. This will be explained below There are two control

arrows on the right to be used to adjust or change the sensitivity,

frequency, record number and emissivity.

a. To change the Frequency: touch the kHz (frequency), when a highlight appears

around the selected area then use the UP/DOWN arrows to adjust.

b. To change the Sensitivity: touch the sensitivity value, when a highlight appears

around the selected area then use the UP/DOWN arrows to change. Changes in the

sensitivity value will show in the upper left of the screen. An alternative to using the

arrows is to use the intensity level box, which uses a bar graph to indicate intensity.

Touch the box in either the high (right) or low (left) area of the box until the

Sensitivity value (S=) changes as needed).

c. To change to different Record Number: touch the Record Number, when a highlight

appears around the selected area then use the then use the UP/DOWN arrows to the

desired location.

d. To save the data, touch the bottom of the screen and locate the save icon, touch

save, when prompted, touch yes to save.

20

Viewing changes in Decibel Levels:

To view decibel levels the Ultraprobe

must be in the active scan mode. Pull

the trigger in to activate the active scan

mode. To freeze the data for storage,

while pointing or touching the test point

in the active mode, release the trigger.

The data will be frozen on the screen

until it is either stored or the Trigger is

pulled in.

dB/TEMP

The decibel and temperature levels are shown in this screen.

This screen will display the Record number, Decibel, Temperature,

Frequency, Sensitivity Level and an Intensity Indicator box. The Intensity

Indicator box also acts as the sensitivity control. There are two control

arrows on the right to be used to adjust sensitivity and frequency.

To freeze a temperature reading

while continuing to test for decibel

level:

a. Touch the bottom of the display

screen and use the LEFT/RIGHT

arrows until the Temp on/off icon

is shown.

b. Touch the icon to turn off

temperature sensing.

c. When done, locate the Temp on/off icon and touch it again to turn the temperature

reading function back on.

TEMP & EMISSIVITY

To test for Temperature only, select this screen. This is the only operating

screen that can be accessed while in any of the other operating screens

(Main, dB/Temp, Valve). It will only show the temperature. The Emissivity

can be changed on this screen to adjust for a more accurate measurement.

The default emissivity level is 95.

Sensitivity value

Frequency

Intensity Level Box

21

To test for a temperature the instrument must be in the active scan mode:

d. Pull the trigger to activate the Active Scan Mode.

e. To freeze the data for storage, while pointing or touching the test point in the active

mode, release the trigger. The data will be frozen on the screen until it is either

stored or the Trigger is pulled in.

f. To adjust the Emissivity: touch the emissivity value and use the UP/Down arrows to

reach the desired level.

g. To save the data, touch the bottom of the screen and locate the save icon, touch

save, when prompted, touch yes to save.

VALVE/STEAM (ABCD)

To use the ABCD screen the VALVE or STEAM application must be selected

in the setup mode. The ABCD icon will be displayed in the Home Screen.

Go to the Home screen after selecting Valve in the setup application mode

to use.

To enter the decibel values of test

points A,B, C and D:

a. Touch a valve test point A, be sure

the instrument is in active test mode.

Freeze the reading on the screen by

releasing the trigger. touch the blank

A lines and the dB reading will

populate that section.

b. Touch valve test point B, be sure the instrument is in active test mode. Freeze the

reading on the screen by releasing the trigger, touch the blank B lines and the dB

reading will populate that section.

c. Touch valve test point C, be sure the instrument is in active test mode. Freeze the

reading on the screen by releasing the trigger, touch the blank C lines and the dB

reading will populate that section.

d. Touch valve test point D, be sure the instrument is in active test mode. Freeze the

reading on the screen by releasing the trigger, touch the blank D lines and the dB

reading will populate that section.

22

e. When done, touch the bottom of the screen and locate the save icon, touch save,

when prompted, touch yes to save.

SPECTRALYZER

The onboard Spectralyzer displays sound events in either an FFT screen, a

Time Series Screen or Both screens at the same time. There are 6 buttons

to use at the bottom of the displayed screen: START/STOP, PLAY,

CAPTURE, REC, SETTINGS, AND EXIT.

Start/Stop: When the Spectra screen

opens it will start to display sounds sensed

by the Ultraprobe, to stop this, touch the

Square Red icon to STOP, to start testing a

sound sample, touch it again to start.

Play: To play a recorded sound back on the

Ultraprobe and to view it while hearing it,

touch the Green Arrow icon to play.

Capture: To capture an image of the screen, touch the third icon from the left. This

image can be used in reports.

Record: To record sound sample touch this Round Red icon. If in the MANUAL record

mode, press the REC icon. To stop in the Manual mode, press STOP. If the instrument

has been set for a preset recording time in the Setup Mode, then just touch and release

the record icon.

Exit: Touch this icon to exit to a previously selected screen.

Levels: To set up the Spectralyzer, touch the “Settings” icon once

Spectralyzer

is open. The first screen has adjustments for setting the levels for the

Spectra screen and for the Time Series Screen. There are 3 adjustments:

dB (decibel) Scale: This can be used for both the Spectra and Time Series screens.

Freq (Frequency) Scale: This is used in the Spectra Screen.

Time Scale: This allows for adjustments to the ms or milliseconds.

To exit back to the main Spectra screen, select Done.

23

Control: On the bottom-right of the LEVELS screen is the Control box. Labeled “Control”

Touch to enter.

The settings are:

Screen views: Select FFT screen or Time Series Screen or view both on the same

screen by selecting both.

Black /White plot: The default screen colors are blue and yellow, this can be changed

to black and white. In instances where the screen image will be stored and printed,

black and white might be selected to reduce the amount of ink used by a printer.

CPM: instead of using the default Hertz, the scale can be set to read CPM (Cycles Per

Minute).

Log Scale

Average

Linear Scale

Detect Peak

Exit on Save WAV: After a sound sample has been recorded and saved, the

Instrument will exit and return to the previously selected Operating Screens.

When finished adjusting the settings or to exit back to the Spectra Screen, select

“Done”.

STORING A RECORD

a. Release the trigger to freeze the desired reading

b. Locate the Store Record icon

c. Touch the “Save” icon.

ENTERING TEST DATA

a. Locate the Input Data icon

b. The Test data information will vary with each application. The title of

the information will be shown in the upper left part of the screen

c. To move from one selection to another, use the Left/Right arrows

d. Touch the screen of the desired data (ex: RPM or TEMP).

24

e. Use the UP/DOWN arrows to enter the desired data.

f. These input data fields are set (and may be changed) in Ultratrend DMS.

VIEW RECORD

A record can be viewed in an operational screen. The record number can

be changed to display the record desired.

a. Touch the Record box

b. Use the UP/DOWN arrows to locate the desired record number

c. Locate the View Record icon

d. Touch the icon

e. When the data appears, all of the stored data can be reviewed by scrolling up or

down with a stylus or finger.

VIEWING A ROUTE

a. Locate the Route icon by touching the bottom of the display screen

b. Touch the Route icon

c. Sorting Route Criteria: Using the SORT button, every time it is pressed

it will rotate the sort. Sort options are: Record #, Low Status, High

Status, OK Status or Not Updated.

d. Reviewing a Photo: If a Y is shown in the “Photo” column (Camera icon) the user can

view the image by touching the Y. If multiple images are stored, touching the display

screen shuffle through all images stored to that location.

e. Reviewing Wave Files: If a wave file is stored, it is possible play either the baseline or

current wave file. To play the baseline, touch the Y in the WAV file column (Speaker

icon) and play.

f. To open the record in the main dB display, touch the Record #.

25

CAMERA

To take a photo of a test point, touch the Camera icon. The Camera screen

will show:

a. Flash: On/Off: The flash is on by default. To turn the flash “Off”,

touch the flash icon. A red line will appear through the icon indicating

it is off.

b. Zoom: To zoom in or out (up to 3X),

touch the zoom box at the desired

zoom location. The zoom level will be

displayed to the left of the zoom box.

c. To capture a photo, touch the View

Photo icon and the image will be

shown on the screen.

d. Touch the image screen to capture

the photo.

e. The photo will appear with the test data superimposed on it. There will also be a

second duplicate photo without the data superimposed. Either one can be used for

reports.

f. To save, press the Save icon. A pop-up box will appear asking; “Save Picture?” To

save the photo, touch “Yes”. Press “No”, if is not to be saved. Touch the Exit icon to

return to previous screen without saving the image. The user can start again to

capture the desired photo.

STROBE

To capture an RPM, touch the

Strobe icon. The Strobe screen

will look like this:

a. Turn the flash feature on by

touching the flash icon with

the red dash through it. The

dash will disappear.

b. Adjust the RPM as needed. (The max is 4000 and the min is 1)

c. To take a picture of the asset with the RPM superimposed on the picture, touch the

Camera icon. (This is optional)

26

d. To save the RPM, touch the Save icon. The RPM will be transferred to the DMS

software later.

e. Touch the Exit icon to exit.

NOTE:

The RPM data will be stored in the “RPM” field under the “Record Information” tab

once the data is transferred from the UP15000 into the DMS software.

BLUETOOTH

To enable Blutooth go to settings There are two options; “Enable” or

“Disable”. This option allows for connection of the audio feed to be

connected to a Bluetooth headphone or earbuds. If this is enabled, a

Bluetooth icon will appear in the Setup screen.

TRIGGER SWITCH

The Trigger Switch is used to display the active dB reading. To observe the active dB

reading, pull the trigger and hold it. For example, when scanning a leak or electric

emission, pull the trigger in and scan the test area until you want to freeze the reading

for storage or review. At that moment, release the trigger. To store the dB frozen on the

screen, select the Save icon.

The trigger can also be used to turn on the Laser Pointer.

NOTE:

The Laser Pointer will work only if it has been set to ON in the setup menu.

QUICK CHANGE BATTERY

To insert the battery, align the battery with the handle

(arrow pointing towards the trigger) and push in until the clips

snap in place.

To remove the battery, push firmly on the battery clips with the fingers of one hand

while holding your other hand under the handle to catch the released battery.

WRIST STRAP

To protect the instrument, against being dropped accidentally, use the wrist strap.

27

HEAD SET JACK

This receives the headset jack. Be sure to plug it in firmly

until it clicks.

RECHARGE JACK

This Jack receives the plug from the recharger. The

recharger is designed to plug into a standard electrical

receptacle.

CHARGING POD

Keep a backup battery fully charged using the Charging Pod. This is a

battery recharge docking station for charging Ultraprobe Batteries

(Lithium Ion). This pod will charge the standard batteries that come

with the Ultraprobe 15,000 while removed from the metered pistol

housing.

28

USERS INSTRUCTIONS

TRISONIC

TM

SCANNING MODULE

This module plugs into the front end of the instrument.

Align the pins located at the rear of the module with the four jacks in the front end of the

Metered Pistol Housing (MPH) and plug in.

For general use position the frequency selection to 40 kHz.

Start to scan the test area.

METHOD OF AIRBORNE DETECTION

The method of air borne detection is to go from the "gross to the fine". Start at maximum

sensitivity (S=70), constantly reducing the sensitivity and following the bar graph amplitude

display to the loudest point. If there is too much ultrasound in the area, reduce the sensitivity,

place the RUBBER FOCUSING PROBE (described below) over the scanning module and proceed.

Every time the sound level rises to a point where it is difficult to follow, reduce the sensitivity

again and again until you are able to follow the test sound to its' loudest point.

HEADSET

The DHC2-HH headphones are designed to be worn with hard hats. To use, simply plug the

headset cord into the headset Jack on the pistol housing, and place the headphones over your

ears.

RUBBER FOCUSING PROBE

To use, simply slip it over the front of the scanning module or the contact module.

NOTE:

To prevent damage to the module plugs, always remove the module BEFORE

attaching and/or removing the Rubber Focusing Probe.

29

LONG RANGE MODULE (LRM)

This module plugs into the front end of the instrument.

Align the pins located at the rear of the module with the four jacks in the front end of the

Metered Pistol Housing (MPH) and plug in.

For general use position the frequency selection to 40 kHz.

Start to scan the test area.

STETHOSCOPE MODULE

Align the pins located at the rear of the module with the four jacks in the front end of

the Metered Pistol Housing (MPH) and plug in.

Touch test area.

As with the SCANNING MODULE, go from the "gross" to the "fine". Start at maximum sensitivity

(S=70) on the Sensitivity Selection dial and proceed to reduce the sensitivity until a satisfactory

sound level is achieved. At times, it may be necessary to utilize the STETHOSCOPE MODULE with

the sensitivity level at or near maximum. Occasionally when in this situation stray ultrasound may

interfere with clear reception and be confusing. If this occurs, place the RUBBER FOCUSING

PROBE over the Stethoscope probe to insulate against the stray ultrasound.

STETHOSCOPE EXTENSION KIT

Remove the Stethoscope Module from the Metered Pistol Housing.

Unscrew the aluminum rod in the Stethoscope Module.

Match the Stethoscope rod thread to the rod that matches. The "base piece" rod will

have the same thread.

Screw the Base Piece into the Stethoscope Module.

If all 31" (78.7 cm) are to be utilized, locate the middle piece. (This is the rod with a

female fitting at one end) and screw this piece into the base piece.

Screw third "end piece" into middle piece.

If a shorter length is desired, omit step 5 and screw "end piece" into "base piece".

30

RMT

Align the pins located at the rear of the module with the four jacks in the front end of the

Metered Pistol Housing (MPH) and plug in. Place the magnetic transducer on the test location.

TO CHARGE THE UP15,000

Plug recharger cable into recharger jack on the UP10000 and then plug the recharger

into a wall receptacle.

Make sure that the LED on the charger is blinking when recharging.

The LED remains solid when the battery is charged. The instrument may stay

connected to the charger without damaging the battery. Charge time is

approximately 4 hours.

WARNING: Use the supplied UE Systems recharger (BCH-10L) only. Use of unauthorized

rechargers will void the warranty and may degrade or damage the battery.

WARBLE TONE GENERATOR / SENSITIVITY VALIDATION UNIT

(UE-WTG-1)

The Tone Generator has two functions.

Sensitivity Validation: This is a procedure that should be incorporated BEFORE

performing any test with the Ultraprobe. It provides assurance that the instrument is

working properly to provide repeatable, reliable results for any inspections. This is a

procedure that is recommended for any Predictive Maintenance instrument used. If

performed regularly it will promote accuracy and test reliability throughout the PdM

program.

For detailed instructions, refer to Appendix A: “Sensitivity Validation Procedure”

As a method for locating large leaks when it is difficult to produce pressure

or vacuum. To perform this test:

a. Turn Tone Generator on by selecting either "LOW" for a low amplitude signal or

"HIGH" for high amplitude. When the Tone Generator is on, a red light (located

below the recharge jack in the front) flickers.

b. Place the Warble Tone Generator within the test item/container and seal or close

it. Then scan the suspect areas with the TrisonicTM Scanning Module in the

Ultraprobe and listen for where the "warble" ultrasound penetrates.

31

TO CHARGE THE WARBLE TONE GENERATOR

Plug recharger cable into recharger jack on the Warble Tone Generator and then plug

the recharger into a wall receptacle.

Make sure that the red LED on the charger is lit when recharging.

The LED turns OFF when the battery is charged.

HELPFUL HINT

Review the applications section to become familiar with the basic inspection methods to ensure

repeatable, reliable results.

AUTO-SHUTDOWN BATTERY FEATURE

The Ultraprobe 15,000 is equipped with an auto-shutdown feature when the battery energy is

depleted. A message in the Display Panel will read “RECHARGE BATTERY”, and the instrument will

go into a “sleep” mode. The instrument will automatically store all records onto the SD card at

shutdown. After the battery is replaced with a freshly charged battery, turn the Ultraprobe 15,000

back on to continue testing.

32

CONSTRUCTION

CIRCUITRY

FREQUENCY

RANGE

RESPONSE TIME

DISPLAY

SOUND

RECORDING

IR TEMPERATURE

CAMERA

LASER POINTER

MEMORY

BATTERY

OPERATING TEMP.

OUTPUTS

PROBES

HEADSET

INDICATORS

SENSITIVITY

THRESHOLD*

DIMENSIONS

WEIGHT

WARRANTY

DISPLAY MODES

Hand-held pistol type made with coated aluminum and ABS plastic.

Solid State Analog and SMD Digital Circuitry with temperature

compensation and true RMS conversion.

20 KHz to 100 KHz (tunable in 1 KHz increments)

< 10 ms

QVGA Touch Screen - IR, Laser Pointer, Camera, Spectrum Analyzer

WAV File Format

-20°C to 500°C (-4 °F to 932 °F )

2.0 megapixels

North America: Output <5mW – Wavelength 640nm – Class IIIa Laser

Product

Europe: Output <1mW – Wavelength 640nm – Class II Laser Product

400 storage locations

Lithium ION Rechargeable

32°F to 122°F (0°C to 50°C)

Calibrated heterodyned output, decibel (dB) frequency, SD card

Trisonic Scanning Module, Stethoscope Module, Long Range Module and

RMT

Deluxe noise attenuating headphones – for hard hat use

dB, Frequency, Battery Status and 16 Segment Bar Graph

Detects .005” (.127 mm) diameter leak @ 5 psi (.34 bar) at a distance of

50 ft. (15.24 m)*

1 x 10 -2 std. cc/sec to 1 x 10 –3 std. cc/sec

Complete kit in Zero Halliburton aluminum carrying case 21.5” x 18.5” x 8”

(55 x 47 x 20 cm)

Pistol Unit: 2.35 lbs. (1.1 kg). Complete carrying case: 19 lbs. (8.6 kg)

5-year parts/labor standard

dB (main), IR, ABCD, Spectrum and Application Specific, Spectrum

Analyzer (modes): Spectrum, Time Series & Dual Specific

*depends on leak configuration

ULTRAPROBE 15,000 SPECIFICATIONS

33

Ultraprobe 15,000 Kit: Meets and exceeds ASTM E1002-2005 requirements for Leak

Detection.

Covered by one or more of the following patents: 0151115; 0303776; 0315199;

1206586; 1297576; 1881263; 2562758; 2689339; 4416145; 4823600; 5955670;

6122966; 6339961; 6341518; 6415645; 6655214; 6707762; 6804992

© 2010 UE Systems, Inc. Made in USA. UE 15 – 0110

UE Systems is committed to continual product improvement; therefore, specifications are

subject to change without notice. Warranty details are available by request.

34

INSTRUCTIONS FOR SETTING COMBINATION ON

CARRYING CASE

The combination is factory set at --0--0--0

SETTING YOUR PERSONAL COMBINATION

Open the case. Looking at the back of the lock inside the case

you will see a change lever. Move this change lever to the

middle of the lock in a way that allows it to hook behind the

change notch (drawing 1).

Set your personal combination, turning the dials to the desired

combination (i.e. birthday, phone #, etc.).

Move the change lever back to the normal position (drawing

2).

To lock, rotate one or more dials. To open, set to your

personal combination.

INTERNATIONAL PATENTS PENDING

YOUR PERSONAL COMBINATION:

1. 2.

35

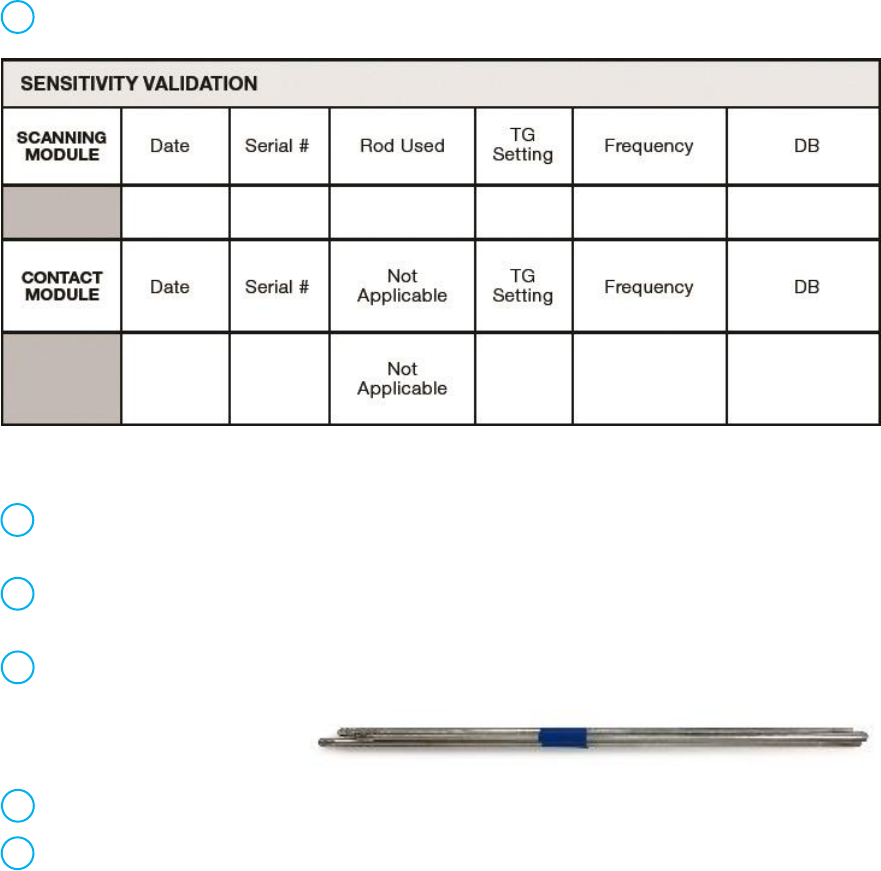

APPENDEX A - SENSITIVITY CALIBRATION

ULTRASONIC TONE GENERATOR METHOD ULTRAPROBE 15000

It is advisable to check the sensitivity of the instrument before proceeding with any

inspection. To assure reliability keep a record of all the sensitivity validation tests and be

sure to keep the Warble Tone Generator charged.

PROCEDURE

1.

Create a chart or use the one below:

A.

For the Scanning Module, insert it into the front end of the instrument.

2.

Select 40 kHz as the test frequency and note “40” in the Frequency box for the

Scanning Module in the Sensitivity Validation Chart

3.

Plug in the Headphones and adjust the ear pieces so that they are open and place

them on the test table

4.

Select the longest of the Stethoscope extension probe rods.

5.

Place an “L” in the Rod used box of the Sensitivity Validation Chart.

6.

Place the Tone generator on the side with the front facing the user.

36

7.

Place the rod in the middle of the transducer are (as above)

8.

Select a volume level on the Warble Tone Generator (Low or High).

9.

Note the level (L or H) in the TG box of the Sensitivity Validation chart.

10.

Turn the Ultraprobe 15,000 on its’ side so that it will rest flat on the test table

with the handle facing the user and the Scanning Module facing the Tone

Generator.

11.

Slide the Ultraprobe gently so that the front faceplate touches the Rod and that the

rod

is touching the face plate while touching the side of the Scanning Module. Align

the Scanning Module so that the center of the module is facing the center of the

Tone Generator Transducer

(on the right).

12.

Adjust the sensitivity until the

intensity bar graph is at mid-line

and displays the decibel level.

13.

Note and record the decibel

reading in the dB box of the

Sensitivity Validation chart.

B.

For the Contact (Stethoscope) Module, insert the Module into the Front End

of the Instrument.

1.

Select 40 kHz as the test frequency and note “40” in the Frequency box for the

Contact Module in the Sensitivity Validation Chart.

2.

Plug in the Headphones and adjust the ear pieces so that they are opened up and

place them on the test table.

3.

Place the Warble Tone Generator flat facing up with the recharge jack facing the

user at 90o.

4.

Select a volume level on the Warble Tone Generator (High or Low).

WTG on Side Recharge Jack on Left,

Volume Control on right

ROD

37

5.

Note the level (H or L) in the TG box of the Sensitivity Validation chart.

6.

With the handle facing the user, align the tip of the contact

probe with the recharge jack and allow the probe to rest on

the jack. DO NOT PRESS DOWN!

7.

(NOTE: NEVER USE THE ALUMINUM EXTENSION PROBE

RODS THEY WILL SHORT OUT THE BATTERY OF THE WTG).

8.

Adjust the sensitivity until intensity bar graph is at mid-line.

9.

Note and record the decibel in the dB box of the Sensitivity

Validation chart.

For all tests:

When performing a Sensitivity Validation Test, review the data in the Sensitivity

Validation chart and repeat the test using the same rod/module, frequency, and

Warble Tone Generator volume setting.

Look for a change in the decibel reading. A change of greater than 6 dB will indicate a

problem.

38

Need further support?

Want information regarding products or training?

CONTACT:

UE Systems, Inc. 14 Hayes Street, Elmsford, NY 10523 USA

T: 914-592-1220 | E: info@uesystems.com | W: www.uesystems.com