Copyright © 2018, 2020 MiTek

®

. All rights reserved.

Patented. See Legal Notice for list of patents.

Manual applies to United States equipment.

CAUTION

MiTek recommends printing this manual in high resolution using color ink. Many of the

graphics may be unclear and may create an unsafe condition if this recommendation is not

followed.

001090 rev. C

Equipment Manual

Roof Truss Tables

MiTek Machinery Division

301 Fountain Lakes Industrial Drive

St. Charles, MO 63301

Phone: 800-523-3380

Fax: 636-328-9218

www.mitek-us.com

Equipment Manual

Roof Truss Tables

Part # and Rev. 001090 rev. C

Print Date 13 July 2022

Effectivity 31580-xxx

31595-xxx

31610-xxx

Revision Date 21 May 2021

Revised By A. McIntire

Orig. Release Date 1 April 2007

Created By R. Widder

Original Instructions: 001090 rev. C ii

Legal Notice

Patents

Made and sold under one or more of the following patents:

Return Goods Policy

Return goods cannot be accepted without prior authorization and are subject to a

restocking charge. The Seller certifies the articles specified herein were produced in

compliance with all provisions of the Fair Labor Standards Act of 1938, as amended,

including Section 12.—Rev. 6/98.

Corrections and Improvements

To report errors or recommend improvements to this manual, please complete the

Document Evaluation Form in the appendices. Mail or fax the form to:

MiTek Machinery Division

301 Fountain Lakes Industrial Drive

St. Charles, MO 63301

Attn: Engineering Manager, Fax: 636-328-9218

U.S. 4,986,052 U.S. 5,837,014 U.S. 6,219,975

U.S. 5,385,339 U.S. 5,854,747 U.S. 6,260,263

U.S. 5,493,834 U.S. 5,873,567 U.S. 6,317,980

U.S. 5,568,862, U.S. 5,884,448 U.S. 6,389,762

U.S. 5,630,697 U.S. 5,885,731 U.S. 6,401,422

U.S. 5,636,494 U.S. 5,906,264 U.S. 6,412,246

U.S. 5,638,658 U.S. 5,934,866 U.S. 6,418,601

U.S. 5,640,832 U.S. 5,947,460 U.S. 6,539,615

U.S. 5,655,399 U.S. 5,987,828 U.S. 6,666,367

U.S. 5,678,395 U.S. 5,996,303 U.S. 6,702,269

U.S. 5,702,095 U.S. 6,048,165 U.S. 6,758,022

U.S. 5,707,204 U.S. 6,112,968 U.S. 6,817,392

U.S. 5,735,087 U.S. 6,134,775 U.S. 6,834,470

U.S. 5,810,341 U.S. 6,170,688 U.S. 6,907,820

U.S. 5,819,412 U.S. 6,205,637 Other patents may apply

U.S. 5,833,222 U.S. 6,212,849

Original Instructions: 001090 rev. C iii

Notice of Change

Roof Gantry Tables

Use this page to record service bulletins and notices that you receive to keep your manual

updated.

Number Date Title

Original Instructions: 001090 rev. C iv

Table of Contents

Legal Notice ii

Patents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Return Goods Policy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Corrections and Improvements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Notice of Change iii

Safety (English) vii

Safety Indicator Signal Words . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Safety Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

General Equipment Safety Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Lockout/Tagout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Troubleshooting with an Energized Machine. . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

Safety Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Restricted Zone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

Safety Symbol Definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

Declaration of Safety Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxi

Seguridad (Español) xxii

Indicadores de seguridad: Palabras de aviso . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

Requerimientos de seguridad. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiii

Reglas general de seguridad para el equipo. . . . . . . . . . . . . . . . . . . . . . . . . . xxiii

Bloqueo/Etiquetado . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxvii

Solución de problemas con una máquina energizada. . . . . . . . . . . . . . . . . . . xxx

Prueba de seguridad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxxi

Zona Restringida . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxxii

Información adicional . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxxii

Introduction 1

Introduction to the Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Purpose of This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Scope of This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

The Drawing Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Website . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Phone or E-mail Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Contact Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

General Information 5

Introduction to the Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Purpose of the Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Description of the Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Safety Compliance of the Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Components Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installation 8

Installation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Infrastructure Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table of Contents

Original Instructions: 001090 rev. C v

Responsibilities During Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Responsibilities Before Moving or Selling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Marking Restricted Zone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Marking Area on Your Own . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Installing MiTek Restricted Zone Tape . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Local Codes and Regulations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Operation 12

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Operator Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Stopping the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Understanding the Table Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Control Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Operating Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Operating the Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Operating the Pneumatic Ejection System . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Maintenance 17

Performing Maintenance Safely . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Before Operating This Machine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Lockout/Tagout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Important Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Making Adjustments and Replacing Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Wearing Personal Protective Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Testing the Safety of the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Cleaning and Inspecting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Inspecting the Ejectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Inspecting the Ejection System as a Whole . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Pneumatic System Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Removing Pressure from the Pneumatic System . . . . . . . . . . . . . . . . . . . . . . . 22

Filter/Regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Setup Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Control Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Ejector Cylinders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

High Slope Ejector Bumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Troubleshooting 29

Safety Notes for Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

General Troubleshooting Safety Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Electrical Troubleshooting Safety Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Getting Started with Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

First Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Problems and Solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Parts List 34

Ordering Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Stocking Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Safety Notes for Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

List of Parts to Keep in Stock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Maintenance Checklist 36

Using the Maintenance Checklists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Safety Notes for the Maintenance Checklists . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Table of Contents

Original Instructions: 001090 rev. C vi

Drawing Set 38

Document Evaluation 39

Document Evaluation Form . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

General Evaluation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Specific Evaluation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Glossary 41

Index 45

Original Instructions: 001090 rev. C vii

Safety (English)

Safety Indicator Signal Words

The following signal words and colors are used throughout this document to indicate

safety hazards. Pay careful attention when you see them. The level of severity differs for

each signal word and color.

Signal words are accompanied by graphics showing what personnel should or should not

do. The graphics are called safety symbols and are defined on page xvii, but more specific

text is provided every time a graphic is used throughout the manual. Everyone near the

machine must be trained on how to read these safety indicators.

Failure to comply with the instructions accompanying each signal word may result in

property damage, personal injury, or even death. Personnel must follow all safety

procedures and practices to ensure the safest possible operation of this equipment.

However, at no time is this document a substitute for common sense. Personnel must

ensure that the work environment is safe and free of distractions.

Purpose

of Chapter

This chapter explains general information and specific procedures for operating

the machine safety.

danger

Indicates an imminently hazardous situation which, if not avoided, is likely to

result in death or serious injury.

warning

Indicates a potentially hazardous situation, which, if not avoided, may result in

death or serious injury.

caution

Indicates a potentially hazardous situation which, if not avoided, may result in

minor or moderate injury.

notice

Calls attention to information that is significant to understanding the operation at

hand or the potential for property damage.

environmental

Applies to conditions that may affect the environment but do not have an

immediate, direct effect on personnel or equipment.

Refiérase a la

pagina xxii para

español.

For safety

information in

Spanish, refer to

page xxii

Safety

Original Instructions: 001090 rev. C viii

Safety Requirements

Because it is impossible to anticipate every circumstance that might involve a hazard, the

safety information provided in this equipment manual and on the machine is not all-

inclusive. If this machine is operated or serviced using a procedure not specifically

recommended by the manufacturer, the procedure shall be approved by a professional

engineer to ensure it will not render the equipment unsafe. Use extreme caution and

common sense at all times.

General Equipment Safety Rules

Know Your Equipment

• Read this manual completely before using or maintaining the equipment. Do not

operate this machine unless you have a thorough knowledge of the controls, safety

devices, emergency stops, and operating procedures outlined in this manual.

• Read and follow all safety notes. Failure to comply with these instructions may

result in economic loss, property damage, and/or personal injury including death.

• Refer to the lockout/tagout guidelines on the following pages to safely perform

maintenance and troubleshooting of this equipment.

• Observe and obey all safety labels. Replace worn labels immediately.

• Use this equipment solely for the purpose described in this manual.

• MiTek equipment is designed to work with optional accessories and other MiTek

machines. When applicable, refer to the appropriate equipment manual for

specific safety information.

• Only qualified personnel should attempt to operate or perform maintenance on

this equipment. “Qualified personnel” is defined as:

...a person or persons who, by possession of a recognized degree or certificate of

professional training, or who, by extensive knowledge, training, or experience,

has successfully demonstrated the ability to solve problems relating to the subject

matter and work—ANSI B30.2-1983

...one who has skills and knowledge related to the construction and operation of

the electrical equipment and installations and has received safety training on the

hazards involved—NEC 2002 Handbook

Personal Safety

• Always wear safety glasses and hearing protection in an industrial environment.

• Utilize a filtering face piece (dust mask) when working near sawdust.

• Wear proper clothing and appropriate personal protective equipment (e.g., safety

glasses and hearing protection.) Do not wear loose clothing or jewelry. Confine

long hair by tying it back.

• Use caution when lifting heavy parts or material.

• Pay attention to your surroundings.

Safety

Original Instructions: 001090 rev. C ix

Installing the Equipment

• Follow installation instructions completely.

• This equipment is not for use in a residential area.

Lockout/Tagout

• Before performing maintenance on the pneumatic or hydraulic systems, bleed the

lines to eliminate pressure. Refer to Removing Pressure from the Pneumatic

System.

• Lockout/tagout all energized systems before performing maintenance on them.

Refer to lockout/tagout guidelines in on page xi.

Keeping a Safe Environment

• Keep children away. All visitors should be kept a safe distance from the work

area. Hazards may not be apparent to individuals unfamiliar with the machine.

• Keep work areas well lit.

• Keep the work area clean and free of any trip or slip hazards.

• Do not use the equipment in damp or wet locations, or expose it to rain or snow.

• Minimize dust clouds and protect your equipment by cleaning dust in this manner:

a) Vacuum dust prior to blowing with air

b) Shut down electrical power and sources of ignition

c) If using compressed air, it should be a low compression (no more than 15 psi)

d) Powered cleaning equipment such as vacuums must be consistent with local

governmental codes for use in dusty conditions.

Operating and Maintaining the Equipment

• Ensure that all people, tools, and foreign objects are clear of the restricted zones

before operating this equipment. The restricted zones are shown on page xvi.

• Perform safety tests to ensure all E-stops are working properly before operating

the equipment at the initial startup, after performing any maintenance, and in

accordance with the maintenance schedule.

• In case of machine malfunction, stop the machine immediately using an E-stop

and report the malfunction to a supervisor.

• Never leave the machine running unattended. Turn the power off! Do not leave

the machine until all parts have come to a complete stop and all electrical power

has been shut off.

• Check for worn or damaged parts regularly. Repair or replace them immediately.

• Keep the hydraulic, pneumatic, and electrical systems in good working order at all

times. Repair leaks and loose connections immediately. Never exceed the

recommended pressure or electrical power.

Safety

Original Instructions: 001090 rev. C x

• Check that all safety devices are in working order before each shift starts. All

protective guards and safety devices must be in place before and during use of the

machine. Never disconnect or bypass any safety device or electrical interlock.

• Only qualified maintenance personnel shall remove or install safety devices.

• Periodically inspect the quality of the finished product.

Electrical Safety

• Do not use any liquids in the interior of electrical cabinets.

• When using solvents on and around the machine, remove power to the machine to

eliminate the chance of sparking, resulting in explosion or fire. Wear a respirator

approved for use with solvents. Wear protective clothing, gloves, and safety

glasses.

Safety

Original Instructions: 001090 rev. C xi

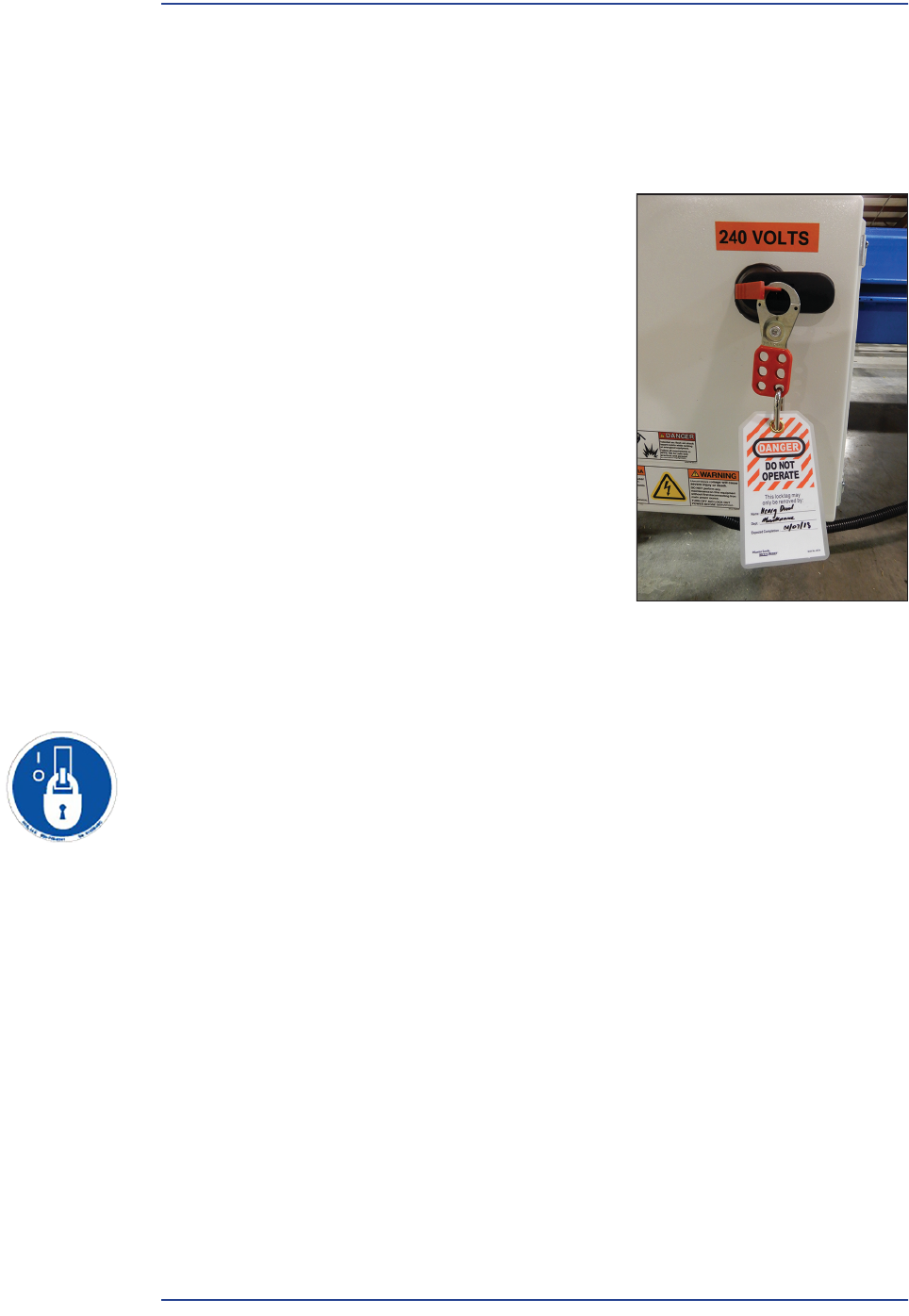

Lockout/Tagout

Lockout/Tagout Guidelines

All lockout/tagout guidelines must be met according

to OSHA 29 CFR 1910.147. A specific procedure

should be included in your company’s energy control

program. This manual is not intended to replace your

company’s de-energizing or lockout/tagout procedure

required by OSHA, but merely to provide general

guidance.

The term “lockout,” as used in this manual, means

placing a lockout device on any and all energy sources to

ensure that the energy isolating device and the equipment

being controlled cannot be re-energized or operated until

the lockout device is removed. Figure 1-2shows where

the electrical disconnects are located for this machine.

• Energy sources include electrical, mechanical,

hydraulic, pneumatic, chemical, thermal, or

other energy.

• In the case of electrical energy sources, the main

power and control power to the machinery must

be turned off and physically locked in the Off position.

• A lockout device is usually a keyed padlock.

If more than one person is working in a restricted zone, use a group lockout device that

will allow each person to use a lock that can be removed only by the person performing

the maintenance.

“Tagout” means that a prominent warning is securely fastened to an energy-isolating

device to indicate that the equipment shall not be operated.

Whenever you see this symbol, lockout/tagout!

Figure 1-1: An Example of a

Lockout/Tagout Device

Safety

Original Instructions: 001090 rev. C xii

Electrical Lockout/Tagout Procedures:

Outside Machine’s Enclosure

Before performing maintenance on any machine with electrical power, lockout/tagout the

machine properly. When working on a machine outside of the machine’s main electrical

enclosure, not including work on the electrical transmission line to the machine, follow

your company’s approved lockout/tagout procedures which should include, but are not

limited to the steps here.

1. Engage an E-stop on the machine.

2. Turn the disconnect switch handle to the Off position. See Figure 1-2.

3. Attach a lock and tag that meet OSHA requirements for lockout/tagout.

4. Restrain or de-energize all pneumatic components, hydraulic components, and

other parts that could have live or stored power.

Figure 1-2: Disconnect Switches to Lockout /Tagout for Various Maintenance

If you are working inside the machine’s enclosure, follow the

procedure on page xiii.

!

WARNING

ELECTROCUTION HAZARD.

When the disconnect switch is off, there is still live power within

the disconnect switch’s enclosure. Always turn off the power at

the building’s power source to the equipment before opening this

electrical enclosure.

Safety

Original Instructions: 001090 rev. C xiii

Electrical Lockout/Tagout Procedures:

Inside Machine’s Enclosure

Before opening the main electrical enclosure, or attempting to repair or replace an

electrical transmission line to the machine, lockout/tagout the machine properly. Follow

your company’s approved lockout/tagout procedures which should include, but are not

limited to the steps here.

1. Engage an E-stop on the

machine.

2. Shut the power to the machine

off at the machine’s power

source which is usually an

electrical service entry panel

on the facility wall. One

example of a locked-out power

source panel is shown in

Figure 1-3.

3. Attach a lock and tag that

meets OSHA requirements for

lockout/tagout.

4. Open the door to the enclosure

in which you need access, and

using a multimeter, verify that

the power is off.

If you are working on the electrical transmission line to the

machine, follow the procedure on page xii.

Figure 1-3: Sample of a Lockout/

Tagout Mechanism on a Power

Source Panel

Safety

Original Instructions: 001090 rev. C xiv

Pneumatic System Lockout/Tagout Procedure: WITH Lockout/Tagout

If working on components other than the pneumatic system, but that requires you to be

near the vicinity of movable pneumatic components, you must, at a minimum, physically

restrain the pneumatic components from moving. If this is not possible, lockout/tagout the

entire pneumatic system.

Pneumatic System Lockout/Tagout Procedure: WITHOUT Lockout/Tagout

Before attempting repair or maintenance on a pneumatic line or component, lockout/

tagout the machine properly. Follow your company’s approved lockout/tagout procedures.

Troubleshooting with an Energized Machine

Only a qualified electrician, using the personal protective equipment and following the

procedures recommended in NFPA 70E should ever attempt service or repair of or near an

energized area or component of the machine.

Whenever maintenance is performed while the equipment is electrically energized, there is

a potential electric arc flash hazard. Refer to NFPA 70E for the personal protective

equipment required when working with electrically energized components. Pneumatic and

hydraulic components may move unexpectedly if not de-energized. Physically restrain any

components capable of movement when working on or near those components.

Safety

Original Instructions: 001090 rev. C xv

Safety Tests

This test procedure MUST be performed by qualified personnel at startup and after ANY

maintenance, adjustment, or modification.

1. Ensure air pressure is set to 100 PSI. See Adjusting the Pressure.

2. Actuate each setup to test that the ejectors raise when expected and lower when

expected at a reasonable speed.

Safety

Original Instructions: 001090 rev. C xvi

Restricted Zone

Figure 1-4: Know the Restricted Zone

Marking the Restricted Zone

The restricted zone must be marked so everyone near the equipment can clearly see the

area where danger may exist. See page 10 for more details.

!

DANGER

Stay out of the restricted zone when equipment is in use. Serious

injury or death may result if personnel are in the restricted zone.

Always look for personnel in the restricted zone before operating

equipment.

Gantry Head

Tables

Parking Stand

Conveyors

Finish Roller

Conveyors

Stackers

(Not Shown)

Safety

Original Instructions: 001090 rev. C xvii

Safety Symbol Definitions

The safety symbols shown in this section are found throughout the manual to indicate

hazards related to this machine. All personnel expected to operate or maintain this

machine should be familiar with these safety symbols and their meanings.

User caution. It indicates a condition where equipment damage

resulting in injury could occur if operational procedures are not

followed. To reduce risk of damage or injury, refer to accompanying

documents, and follow all steps or procedures as instructed.

Electrical hazard. It indicates dangerous high voltages inside of an

enclosure and/or the presence of a power source. To reduce the risk

of fire or electric shock, do not attempt to open the enclosure or gain

access to areas where you are not instructed to do so. Refer

servicing to qualified service personnel only.

This equipment should be operated only from the type of source

indicated on the manufacturer’s identification label. Installation

should be in compliance with applicable sections of the national

electric code. Consult your local building code before installing.

Crush hazard. Keep hands clear.

Trip hazard. Pay attention when walking in this area.

Keep hands and body clear.

Safety

Original Instructions: 001090 rev. C xviii

Keep hands away from moving parts.

High pressure hose. Use appropriate PPE when working on

equipment. Maintain safe pressure level at all times.

Use sling equipment rated for at least ___ lbs / ___ kgs when lifting

this equipment.

Do not use unapproved lubricants in this equipment.

Do not operate without guards in place.

Indicates notes regarding lubrication.

Safety

Original Instructions: 001090 rev. C xix

The operation of this equipment requires the use of PPE.

Do not operate without wearing the required protective clothing.

Refer to manual. After installation, read the user’s guide carefully

before operating. Follow all operating and other instructions

carefully.

Safety

Original Instructions: 001090 rev. C xx

Circuits are live. Lockout/tagout on the upstream disconnect prior to

servicing.

Lockout in a de-energized state.

Lift point. In order to decrease the likelihood of damage to the

equipment, use only the lift points indicated in the manual.

To reduce the risk of equipment damage or injury to personnel,

maintain pressure at safe levels.

Read all safety warnings and instructions before proceeding.

No lift point. Do not lift this device with a hook/crane assembly.

Equipment damage occurs. Refer to the installation instructions.

Safety

Original Instructions: 001090 rev. C xxi

Declaration of Safety Conformity

Conforms electrically to the following:

• NFPA 79

• NEC Electrical Code

• Electrical enclosures carry UL 508A and the CUL for Canada

• Safety circuit conforms to Category 4 redundant monitoring

Conforms mechanically to the following:

• 10CFR 1910

• ANSI B 11.19

Original Instructions: 001090 rev. C xxii

Seguridad (Español)

Indicadores de seguridad: Palabras de aviso

Las siguientes palabras y colores de aviso se utilizan a lo largo de este documento para

indicar riesgos de seguridad. Preste suma atención cuando los vea. El nivel de gravedad es

diferente por cada palabra o color de aviso.

Las palabras de aviso van acompañadas por gráficos que muestran al personal lo que

deben y no deben hacer. Los gráficos se llaman símbolos de seguridad y se definen en la

página xvii pero se proporciona un texto más específico cada vez que se utiliza un gráfico

por todo el manual. Todas las personas que estén cerca de una máquina tienen que ser

capacitadas en cómo leer estos indicadores de seguridad.

No cumplir las instrucciones que acompañan cada palabra de aviso puede producir daños a

la propiedad, lesiones personales e incluso la muerte. El personal debe seguir todos los

procedimientos y prácticas de seguridad establecidos para asegurar el uso más seguro

posible de este equipo. No obstante, en ningún caso este documento reemplaza el sentido

común. El personal debe asegurarse de que el entorno de trabajo sea seguro y esté libre de

distracciones.

Objetivo

del Capítulo

Este capítulo explica la información general y los procedimientos específicos

para operar la máquina de manera segura.

Peligro

Indica una situación de peligro inminente que, si no se evita, ocasionará la

muerte o graves lesiones.

Advertencia

Indica una situación potencialmente peligrosa que, si no se evita, podría

producir la muerte o lesiones graves.

Precaución

Indica una situación potencialmente peligrosa que, si no se evita, puede

producir lesiones menores o moderadas.

Aviso

Llama la atención a información importante para entender la operación que se

desea realizar o daños a la propiedad probables.

Ambiental

Se aplica a condiciones que pueden afectar el entorno pero que no tienen un

efecto inmediato o directo sobre el personal o el equipo.

Seguridad

Original Instructions: 001090 rev. C xxiii

Requerimientos de seguridad

Debido a la imposibilidad de anticipar todas las circunstancias que podrían constituir un

riesgo, la información de seguridad suministrada en este manual del equipo y sobre la

máquina no es exhaustiva. Si se utiliza o realiza el mantenimiento de esta máquina

utilizando un procedimiento no recomendado específicamente por el fabricante, el

procedimiento deberá ser aprobado por un ingeniero profesional para asegurarse de que no

afecte la seguridad del equipo. ¡Manéjese siempre con suma precaución y sentido común!

Reglas general de seguridad para el equipo

Conozca su equipo

• Lea este manual en su totalidad antes de utilizar o mantener el equipo. No utilice

esta máquina a menos que esté perfectamente familiarizado con los controles, los

dispositivos de seguridad, los frenos de emergencia y los procedimientos

operativos que se describen en este manual.

• Lea y siga todas las notas de seguridad. El no cumplimiento de estas instrucciones

podría producir pérdidas económicas, daños a la propiedad y/o lesiones

personales, incluida la muerte.

• Refiérase a las pautas de bloqueo/etiquetado proporcionadas en las siguientes

páginas para realizar el mantenimiento y solucionar problemas de este equipo en

forma segura.

• Observe y cumpla con todas las etiquetas de seguridad. Cambie las etiquetas

gastadas inmediatamente.

• Utilice este equipo únicamente para el propósito que se describe en este manual.

• El equipo MiTek está diseñado para funcionar con accesorios opcionales y otras

máquinas MiTek. Cuando sea necesario, consulte el manual del equipo

correspondiente para obtener información de seguridad específica.

• Sólo personal calificado debe intentar utilizar o realizar el mantenimiento de este

equipo. Por "personal calificado" se entiende:

...una persona o personas que, por el hecho de poseer un título o certificado de

capacitación profesional reconocido o que, por sus amplios conocimientos o

experiencia, han demostrado con éxito estar capacitados para resolver problemas

relacionados con el tema y el trabajo en cuestión—ANSI B30.2-1983

...una persona que posee habilidades y conocimientos relacionados con la

construcción y uso de equipos e instalaciones eléctricas y que ha recibido

capacitación en seguridad sobre los riesgos posibles—NEC 2002 Handbook

Seguridad personal

• Use siempre lentes de seguridad y protección auditiva en un entorno industrial.

• Utilice una máscara protectora cuando trabaje cerca de aserrín.

Seguridad

Original Instructions: 001090 rev. C xxiv

• Utilice ropa adecuada y equipo de protección personal apropiado (por ejemplo,

lentes de seguridad y protección auditiva.) No use ropa suelta ni joyas. Si tiene el

cabello largo, áteselo para atrás.

• Proceda con precaución cuando levante piezas o materiales pesados.

Seguridad

Original Instructions: 001090 rev. C xxv

Instalació del equipo

• Siga las instrucciones de instalación al pie de la letra.

• No utilizar este equipo en zonas residenciales.

Bloqueo/Etiquetado

• Antes de realizar el mantenimiento de los sistemas neumáticos, purgue las líneas

para eliminar la presión.

• Bloquee y etiquete todos los sistemas energizados antes de realizar tareas de

mantenimiento en ellos. Refiérase a la sección Pautas de bloqueo/etiquetado en la

página xxvii.

Cómo manterner un entorno seguro

• Mantenga alejados a los niños. Todos los visitantes deben mantenerse a una

distancia segura del área de trabajo. Los riesgos pueden no ser evidentes a las

personas no familiarizadas con la máquina.

• Mantenga las áreas de trabajo bien iluminadas.

• Mantenga el área de trabajo limpia y libre de cualquier riesgo de tropiezo o

resbalamiento.

• No utilice el equipo en lugares húmedos o mojados y no lo exponga a la lluvia o a

la nieve.

• Minimice las nubes de polvo y proteja su equipo quitando el polvo de la siguiente

manera:

• Aspire el polvo antes de soplarlo con aire

• Apague la alimentación eléctrica y todas las fuentes de ignición

• Si usa aire comprimido, debe ser a compresión baja (no más de 15 psi)

• El equipo eléctrico de limpieza como las aspiradoras debe cumplir con los

códigos del gobierno local para uso en condiciones polvorientas.

AVISO

¡No utilice nunca aire comprimido dentro de una caja eléctrica!

Puede forzar sustancias contaminantes hacia el interior de las

conexiones eléctricas.

Utilice un aspirador para eliminar polvo de las cajas eléctricas.

Es aceptable utilizar aire comprimido después de aspirar.

Seguridad

Original Instructions: 001090 rev. C xxvi

Uso y mantenimiento del equipo

• Asegúrese de que no haya personas, herramientas y objetos extraños en las zonas

restringidas antes de utilizar este equipo. Las zonas restringidas se indican en la

página xxxii.

• Realice pruebas de seguridad para verificar que todos los frenos de emergencia

funcionen adecuadamente antes de utilizar el equipo al principio de la puesta en

marcha y después de realizar cualquier tarea de mantenimiento.

• En caso de que la máquina no funcione correctamente, deténgala inmediatamente

utilizando un freno de emergencia e informe el problema a un supervisor.

• No deje nunca la máquina encendida si no está junto a ella. ¡Apáguela! No la

abandone hasta que todas las piezas se detengan completamente y hasta que se

haya apagado la alimentación eléctrica.

• Verifique periódicamente que no haya piezas gastadas o dañadas. Repárelas o

cámbielas inmediatamente.

• Mantenga los sistemas neumáticos y eléctricos en buen funcionamiento en todo

momento. Repare las fugas y las conexiones sueltas inmediatamente. No exceda

nunca la presión ni potencia eléctrica recomendadas.

• Verifique que todos los dispositivos de seguridad estén en buen funcionamiento

antes de comenzar cada turno. Todos los dispositivos protectores y de seguridad

deben estar en su lugar antes y durante el uso de la máquina. No desconecte ni

evite nunca ningún dispositivo de seguridad ni interbloqueo eléctrico.

• Solo el personal de mantenimiento calificado puede quitar o instalar los

dispositivos de seguridad.

• Inspeccione periódicamente la calidad del producto terminado.

Seguridad eléctrica

• No utilice líquidos en el interior de los gabinetes eléctricos.

• Cuando utilice disolventes sobre o alrededor de la máquina, desconecte la

alimentación para eliminar las probabilidades de chispas, que pueden producir

una explosión o incendio. Use un respirador aprobado para el uso con disolventes.

Use ropa protectora, guantes y lentes de seguridad.

Seguridad

Original Instructions: 001090 rev. C xxvii

Bloqueo/Etiquetado

Pautas de bloqueo/etiquetado

Deben cumplir con todas las pautas de bloqueo/

etiquetado conforme a la norma OSHA 29 CFR

1910.147. El programa de control de energía de la

compañía debe incluir un procedimiento específico. El

objetivo de este manual no es reemplazar el

procedimiento de desenergización o bloqueo/etiquetado

requerido por la OSHA, sino proporcionar pautas

orientativas generales.

El término "bloqueo", según se utiliza en este manual, se

refiere a la colocación de un dispositivo de bloqueo en las

fuentes de energía para asegurar que el dispositivo

aislador de energía y el equipo controlado por éste no

puedan reenergizarse o utilizarse hasta que se retire dicho

dispositivo. Las fotos en la página xxviii siguiente

muestran los lugares en los que se encuentran los

interruptores de desconexión eléctrica de esta máquina.

• Las fuentes de energía incluyen energía eléctrica,

mecánica, hidráulica, neumática, química,

térmica y otras.

• En el caso de fuentes de energía eléctrica, la alimentación principal y la

alimentación de control a la maquinaria deben apagarse y bloquearse físicamente

en la posición "off" (apagado).

• Por lo general, como dispositivo de bloqueo se utiliza un candado con llave.

Si hay más de una persona trabajando en una zona restringida, utilice un dispositivo de

bloqueo grupal que permita a cada persona utilizar un candado que sólo pueda ser retirado

por la persona que realiza el mantenimiento.

Siempre que vea este símbolo, ¡Bloquee/Etiquete!

Figura 1-1: Ejemplo de un

dispositivo de bloqueo/

etiquetado

Seguridad

Original Instructions: 001090 rev. C xxviii

Procedimientos de bloqueo/etiquetado eléctricos: fuera del gabinete

Antes de realizar el mantenimiento de cualquier máquina con alimentación eléctrica,

bloquee y etiquete la máquina de forma adecuada. Cuando trabaje en una máquina fuera

del gabinete eléctrico principal de la máquina, salvo en el caso de trabajos en la línea de

transmisión eléctrica a la máquina, siga los procedimientos de bloqueo/etiquetado

aprobados por la compañía, los cuales deberían incluir, entre otros, los pasos aquí

indicados.

1. Coloque un freno de emergencia sobre la máquina.

2. Coloque el mango del interruptor con fusibles en la posición "apagado". Vea

página xxviii.

3. Coloque un candado y una etiqueta que cumplan con los requisitos de bloqueo/

etiquetado de la OSHA.

4. Trabe o desenergice todos los componentes neumáticos y otras piezas que tengan

alimentación directa o almacenada.

Figura 1-2: Mecanismo de bloqueo/etiquetado en un gabinete eléctrico principal

Si trabaja en la línea de transmisión eléctrica a la máquina, siga

el procedimiento de la página xxix.

!

ADVERTENCIA

RIESGO DE ELECTROCUCIÓN.

Cuando el interruptor con fusibles está apagado, sigue habiendo

energía dentro del gabinete del interruptor. ¡Apague siempre la

alimentación en la fuente de alimentación del edificio antes de

abrir este gabinete eléctrico!

Seguridad

Original Instructions: 001090 rev. C xxix

Procedimientos de bloqueo/etiquetado eléctricos: dentro del gabinete

Antes de abrir el gabinete eléctrico principal o intentar reparar o reemplazar una línea de

transmisión eléctrica a la máquina, bloquee y etiquete la máquina en forma adecuada. Siga

los procedimientos de bloqueo/etiquetado aprobados por la compañía, los cuales deberían

incluir, entre otros, los pasos aquí indicados.

1. Coloque un freno de

emergencia sobre la máquina.

2. Apague la alimentación a la

máquina en la fuente de

alimentación, que, por lo

general, es un panel de entrada

de suministro eléctrico que se

encuentra en una pared de las

instalaciones. En la Figure 1-3

se muestra un ejemplo de panel

de fuente de alimentación

bloqueado.

3. Coloque un candado y una

etiqueta que cumplan con los

requisitos de bloqueo/

etiquetado de la OSHA.

4. Abra la puerta del gabinete al

que necesita acceder y usando

un multímetro verifique que la

alimentación esté apagada.

Figura 1-3: Ejemplo de un

mecanismo de Bloqueo/Etiquetado

en un panel de entrada de

suministro eléctrico

Seguridad

Original Instructions: 001090 rev. C xxx

Procedimiento de bloqueo/etiquetado del sistema neumático: cuando no se

requiere bloqueo/etiquetado

Si trabaja con componentes que no son del sistema neumático pero que requieren su

presencia en la proximidad de componentes neumáticos móviles, debe, como mínimo,

trabar físicamente estos componentes para que no se muevan. Si no es posible, bloquee/

etiquete todo el sistema neumático.

Procedimiento de bloqueo/etiquetado del sistema neumático: cuando se

requiere bloqueo/etiquetado

Antes de intentar reparar o realizar el mantenimiento de una línea o componente

neumático, bloquee/etiquete la máquina en forma apropiada. Vea la página xxviii para más

detalles sobre procedimientos de bloqueo/etiquetado neumático. Siga los procedimientos

de bloqueo/etiquetado aprobados por la compañía.

Solución de problemas con una máquina energizada

Sólo un electricista calificado que utilice el equipo de protección personal y siga los

procedimientos recomendados en la norma NFPA 70E debe intentar realizar tareas de

reparación o mantenimiento en un área o componente energizados de la máquina o en su

proximidad.

Cada vez que se realizan tareas de mantenimiento mientras el equipo está eléctricamente

energizado, existe un riesgo potencial de formación de un arco eléctrico. Consulte en la

norma NFPA 70E el equipo de protección personal requerido para trabajar con

componentes eléctricamente energizados. Los componentes neumáticos e hidráulicos

pueden moverse de manera imprevista si no se desenergizan. Trabe físicamente cualquier

componente que pueda moverse cuando deba trabajar en ellos o en su proximidad.

Seguridad

Original Instructions: 001090 rev. C xxxi

Prueba de seguridad

Este procedimiento de prueba DEBE ser realizado por personal calificado al momento de

la puesta en marcha y después de CUALQUIER tarea de mantenimiento, ajuste o

modificación.

1. Asegúrese de que la presión del aire esté ajustada en 100 psi. Vea Ajuste de la

presión.

2. Accione todos los conjuntos neumáticos para comprobar que suban y bajen según

lo previsto a una velocidad razonable.

Seguridad

Original Instructions: 001090 rev. C xxxii

Zona Restringida

Figura 1-4: Conocer la zona restringida

Marcar la zona restringida

La zona restringida deberá marcarse de tal manera que todas las personas que se

encuentren cerca del equipo puedan ver claramente el área donde pueda haber peligro. Vea

!

PELIGRO

Manténgase afuera de la zona restringida cuando el equipo esté

en uso. Pueden producirse lesiones graves o incluso la muerte si

el personal está en la zona restringida.

Asegúrese que no haya personal en la zona restringida antes de

operar el equipo.

Gantry Head

Tables

Parking Stand

Conveyors

Finish Roller

Conveyors

Stackers

(Not Shown)

Chapter 1

Original Instructions: 001090 rev. C 1

Introduction

Introduction to the Manual

Purpose of This Manual

In order for this manual to be useful, it must be accessible.

This manual addresses the most recent version of the equipment as of the date listed on the

title page. For earlier revisions, contact MiTek Machinery Division Customer Service.

This manual is a valuable training tool.

• The Introduction and General Information chapters discuss contact information for

MiTek and provide basic information about the equipment.

• The Operation chapter teaches operators how to efficiently operate the machine.

• The Maintenance chapter details procedures specifically for maintenance

personnel.

• The appendices provide valuable training materials and technical information to

keep your equipment running.

Purpose

of Chapter

This chapter explains how to navigate through the manual and how to contact

MiTek Machinery Division Customer Service.

!

WARNING

Read this manual completely before using this equipment.

Do not operate this equipment until you have a thorough

understanding of all controls, safety devices, emergency stops,

and operating procedures outlined in this manual.

All hazard instructions must be read and observed. Failure to do

so may result in economic loss, property damage, and/or

personal injury.

This manual must always be available to personnel.

Introduction

Original Instructions: 001090 rev. C 2

Scope of This Manual

The Roof Truss Table is designed to work with optional accessories and other MiTek

machines, but the scope of this manual is limited to the following equipment:

Equipment covered in this manual:

• Roof Truss Table

• Ejection Systems (High-Slope Auto-Eject and End-Eject)

Equipment not covered in this manual:

• Roof Press

• Automated or Manual Jigging

• Other peripheral equipment

The Drawing Set

A list of drawings can be found in the back of this equipment manual or in a separate

11x17 binder. The drawings list can be found in the Drawing Set chapter.

Introduction

Original Instructions: 001090 rev. C 3

Navigational Aids

The graphics used in Table 1-1 are used throughout the manual to communicate a specific

type of information quickly.

Table 1-1: Navigational Aids

Graphic Explanation

This icon is an important safety note.

It indicates that you must lockout/tagout at the disconnect switch located

on the equipment using approved methods described in OSHA CFR

1910.147 before continuing with the procedure.

This icon specifies that certain tools are needed before a procedure

begins.

This icon provides additional information to supplement the main text.

This icon indicates how to locate additional relevant information or

resources.

This icon indicates that a part number for the item being discussed is

located in the Parts List appendix.

Introduction

Original Instructions: 001090 rev. C 4

Additional Resources

Website

Visit the MiTek website at mitek-us.com for up-to-date information on all MiTek

equipment. You may also find the following information there:

• The latest revisions of this manual

• Service bulletins pertaining to your equipment

• Support, safety, and training information

• Part numbers for ordering parts

Phone or E-mail Support

To obtain expert technical assistance or to order parts, contact MiTek Machinery Division

Customer Service using one of the following methods.

Contact Information

MiTek Component Automation

Customer Service Department

301 Fountain Lakes Industrial Drive

St. Charles, MO 63301

Parts Orders (with part number)

Email: [email protected]

Technical Assistance

Phone: 800-523-3380

Fax: 636-328-9218

Website

mitek-us.com

Videos

Search for “MiTek Inc” to find us on YouTube

.

Chapter 2

Original Instructions: 001090 rev. C 5

General Information

Introduction to the Equipment

Purpose of the Equipment

The Roof Truss Tables are used with MiTek roof truss presses. All accessories and options

discussed in this manual are designed to work specifically with MiTek Roof Truss Tables

to make setup and material handling tasks more efficient.

Description of the Equipment

The Roof Truss Tables provide a stable, durable jigging surface for the assembly and

pressing of trusses. Trusses are assembled on the table surface and the press passes above

the tables, embedding the plates.

Optional ejection systems can be installed in the tables to lift the trusses off the table for

easy removal. Optional automated and manual jigging can also be installed to drastically

reduce setup time.

Safety Compliance of the Equipment

Equipment shipped to a U.S. destination is compliant NFPA 79, NEC 2009, and applicable

OSHA regulations.

Equipment shipped to an international destination is compliant with CSA regulations.

Purpose

of Chapter

This chapter provides an overview of the equipment and the means to identify it.

General Information

Original Instructions: 001090 rev. C 6

Figure 2-1: Major Components of the Roof Truss Tables (Options Included)

General Information

Original Instructions: 001090 rev. C 7

Components Overview

The main and some of the optional components of the table system are shown on page 6.

All optional components are listed in Table 2-1.

Table 2-1: Optional Features

Technical Specifications

Table 2-2: Dimensions and Weight

Table 2-3: General Specifications

Component Description

Automated Jigging See automated jigging equipment manual.

Ejection Systems High-Slope Auto-Eject (with auto-eject roller)

End-Eject (with gantry lifter)

Table Top Surfaces Walk-through aisles or continuous-top

Table Type Dimensions Approx. Weight

12’-6” Table 13’ 4-3/4” L, x 7’ 6” W, x 30-3/4” adjustable to 34” H 4,800 lbs

14’ Table 14’ 10-3/4” L, x 7’ 6” W, x 30-3/4” adjustable to 34” H 5,600 lbs

16’ Table 16’ 10-3/4” L, x 7’ 6” W, x 30-3/4” adjustable to 34” H 6,000 lbs

Table-top material 3/4” steel

Manual jigging slots 6 slots for jigging

Jigging MiTek-supplied manual jigging is used in manual

jigging slots. Automated jigging is optional and can

replace manual jigging slots.

Chapter 3

Original Instructions: 001090 rev. C 8

Installation

Installation Requirements

Environmental Requirements

Operating Temperature

The Roof Gantry Tables operate properly in its intended ambient temperature, from 40 to

122 degrees Fahrenheit (0 to 50 degrees Celsius).

Relative Humidity

The Roof Gantry Tables operate properly in an atmosphere with 45 to 85 percent relative

humidity.

Transportation and Storage

The Roof Gantry Tables withstand or has been protected against transportation and storage

temperatures from -13 to 158 degrees Fahrenheit (-25 to 70 degrees Celsius). It has been

packaged to prevent damage from the effects of normal humidity, vibration, and shock.

Infrastructure Requirements

Flooring Requirements

The Roof Gantry Tables need to be installed on a floor that meets the minimum

requirements for the press that will be pressing on the tables. Refer to the press manual.

Purpose

of Chapter

This chapter provides a brief overview of the responsibilities in the installation

process.

ENVIRONMENTAL

Do not discard machinery into the municipal waste stream.

Installation

Original Instructions: 001090 rev. C 9

Pneumatic Requirements

The Roof Gantry Tables use a pneumatic system to operate optional jigging components.

To reduce condensation in the pneumatic system, MiTek recommends using a refrigerated

air dryer. Requirements for the pneumatic system are detailed in Table 3-1.

Table 3-1: Pneumatic System Requirements

Specification Technical Data

Volume:

Auto-Eject

End-Eject

.42 scfm per table

.39 scfm per table

Pressure 100 psi

Minimum line from air source 1'' diameter

Recommended line from air source 1'' diameter

Recommended air source tank min. of 60 gallons

Installation

Original Instructions: 001090 rev. C 10

Responsibilities During Installation

MiTek supervises the installation to ensure that the Roof Gantry Tables are installed

properly and operate correctly. MiTek will also provide operating and maintenance

training at the time the equipment is installed. The customer is responsible for providing

all labor and equipment needed to complete the installation.

Responsibilities Before Moving or Selling

If you determine that you want to move your Roof Gantry Tables to another location or

you want to sell your system to another company, please call MiTek Machinery Division

Customer Service. Customer Service provides detailed information that is needed before

installing the system elsewhere.

Marking Restricted Zone

Marking Area on Your Own

The restricted zone must be marked and maintained so everyone near the equipment can

clearly see the area where danger may exist. The customer is responsible for marking and

maintaining the restricted zone.

Installing MiTek Restricted Zone Tape

Your equipment arrived with Service Bulletin SB181, which includes restricted zone tape

and instructions for installing it.

The service bulletin is available online (www.mitek-us.com) as well as through the MiTek

Machinery Division Customer Service Department. Follow the instructions contained in

SB181 to install the restricted zone tape.

!

WARNING

Call MiTek Machinery Division Customer Service before moving

the system.

Moving the system without proper planning may result in

equipment damage or serious injury.

Customer Service

is available at

800-523-3380.

Installation

Original Instructions: 001090 rev. C 11

Local Codes and Regulations

The customer must be familiar with all local codes that apply and ensure the equipment in

installed in a way that meets these codes. The following list identifies some, but not all, of

the items that should be discussed with local authorities.

• Equipment should be stable under all conditions of use, including seismic events

• Fuse and disconnect regulations

• Grounding regulations

• Emissions regulations

• Space required

• Personal protective equipment required

• Inspections required

Chapter 4

Original Instructions: 001090 rev. C 12

Operation

Before You Begin

Purpose

of Chapter

This chapter describes operating mechanisms on this machine and the

procedure to operate it in most circumstances.

!

WARNING

ELECTROCUTION, HIGH PRESSURE, CRUSH, AND CUT

HAZARDS.

Read this section AND the safety section in the preliminary pages

before operating or maintaining this machine.

Do not operate this machine until you have a thorough

understanding of all controls, safety devices, E-stops, and

operating procedures outlined in this manual.

Read and observe all warnings. Failure to do so may result in

economic loss, property damage, and/or personal injury.

This manual must always be available to personnel operating and

maintaining this machine.

!

WARNING

CRUSH AND CUT HAZARD.

Before turning on the machine, make sure that all personnel and

other machines are out of the restricted zone (see page xvi).

!

WARNING

Do not operate this machine unless all guards and safety devices

are in place.

Only qualified maintenance personnel shall repair, remove, or

replace guards and safety devices.

Operation

Original Instructions: 001090 rev. C 13

Operator Controls

Refer to your press or automated jigging manual for additional operating information.

Stopping the Machine

Refer to the press manual for instructions on stopping the press and other safety

information.

Understanding the Table Components

The pneumatic system controls the optional ejectors on the tables.

Control Valves

This section describes how valves control individual tables or setups. A table line may

have multiple setups depending on installation requirements.

1. A foot valve (new models) or hand valve (also referred to as a pilot valve)

is used

to control a setup. See Figure 4-1.

Figure 4-1: Ejector Control Valves

!

WARNING

The operation of this machine requires the use of PPE. Do not

operate without wearing required protective clothing.

Operating this machine without proper PPE may result in injury.

Setup (noun):

A section of the pneumatic system configured to

act as one unit; it controls the air flow for multiple

table ejectors.

Operation

Original Instructions: 001090 rev. C 14

2. The table valves determine whether the ejectors for an individual table functions

within a setup

(Figure 4-2).

Figure 4-2: Table Valve

3. Ball valves installed in the 22-mm tubing are used to designate where a setup

(composed of multiple tables) starts and stops (Figure 4-3).

4. The shut-off valve controls air flow to all tables in a setup (Figure 4-3).

Figure 4-3: Setup Ball Valves and Shut-Off Valve

Operation

Original Instructions: 001090 rev. C 15

Operating Procedure

This manual only addresses the use of the Roof Truss Tables. It does not address methods

of designing or building a truss or operating the jigging.

Operating the Tables

1. Set up the truss configuration and jigging.

Refer to your press manual and jigging manual.

2. When the press has completed its pass over the truss, park the press head out of

the way of the truss.

3. Remove the truss from the table and place it on the Stand-Alone Conveyors.

• For systems using pneumatic ejectors, refer to the Operating the Pneumatic

Ejection System section.

Operating the Pneumatic Ejection System

After the connector plates have been pressed into the truss, if pneumatic ejectors are

present, take the following steps. These steps may differ according to setup configuration.

1. Ensure the press and/or gantry lift (the machine that lifts the roof press) is in the

correct position:

• For auto-eject systems, the press must be clear of the ejectors.

• For end-eject systems, the press must be parked on the gantry lift or at the

opposite end of the table.

2. Remove ALL slider pads from the tables before actuating ejectors.

• If, to aid a work flow, you choose not to remove a specific slider pad, make

sure to disable the ejector associated with that slider pad to avoid damage to

the ejector.

3. Ensure all desired table valves are open.

4. Step on the foot valve (new models) or turn hand valve to the extend position to

raise the ejectors.

• For independent setups:

a) Ensure setup ball valves are in correct positions to isolate setup.

b) If using a foot valve, ensure the shut-off valve for the chosen setup is

open.

!

WARNING

CRUSH AND CUT HAZARD.

Before turning on the equipment, make sure that all personnel

and equipment are clear.

Operation

Original Instructions: 001090 rev. C 16

• For operating entire line as one:

a) Ensure all setup ball valves are in the open position.

b) If using a foot valve, Ensure the shut-off valve connected to the

chosen foot valve is open and close all other shut-off valves.

c) If using a hand valve, ensure all hand valves are in the neutral

position.

5. The ejectors lift the truss off the table.

• For ejection off the side of the tables, the truss should slide onto the Stand-

Alone Conveyors. If auto-eject rollers are present and running, they will

automatically assist with this step.

• On end-eject systems, the pop-up ejectors, the gantry lift, and the press (if

parked on the gantry lift) will raise simultaneously. Push or pull the truss

across the pop-up ejectors to transfer the truss to the end of the table line.

6. Retract the ejectors back into the table by kicking the foot valve plate (new

models) or turning the hand valve to the retract position.

!

WARNING

CRUSH HAZARD.

When removing a truss from an end-eject system, use caution to

avoid coming into contact with the Finish Roller.

Failure to exercise caution may result in severe personal injury.

Chapter 5

Original Instructions: 001090 rev. C 17

Maintenance

Performing Maintenance Safely

Read the safety section starting on page vii and adhere to all rules and guidelines. This

section provides additional safety information specific to maintenance topics.

The recommended intervals for the maintenance items addressed in this section are listed

in Maintenance Checklist.

Before Operating This Machine

Review these warnings before operating this machine.

Purpose

of Chapter

This chapter provides step-by-step instructions and other information to help you

make repairs and perform preventative maintenance.

!

WARNING

HIGH PRESSURE, CRUSH, CUT, AND CHEMICAL HAZARDS

Read this section AND the safety section in the preliminary pages

before operating or maintaining this equipment.

Do not operate this machine until you have a thorough

understanding of all controls, safety devices, E-stops, and

operating procedures outlined in this manual.

Read and observe all hazard instructions. Failure to do so may

result in economic loss, property damage, and/or personal injury.

This manual must always be available to personnel operating and

maintaining this equipment.

!

WARNING

CRUSH AND CUT HAZARD

Guards must always be in place during operation to avoid serious

injury and possibly death.

Always replace guards after completing maintenance and before

removing the lockout/tagout device.

Maintenance

Original Instructions: 001090 rev. C 18

Lockout/Tagout

The lock and tag symbol shown here indicates that proper lockout/tagout procedures must

be used prior to starting the procedure where the symbol occurs.

Important Safety Information

Your Responsibilities

Detailed descriptions of standard workshop procedures, safety principles, and service

operations are not included in this manual. Although this manual contains some warnings

and cautions against specific service methods which could cause personal injury or

damage to the machine, it does not cover all conceivable ways of service which might be

done or the possibility of hazardous consequences of each conceivable way. If you intend

to handle, operate, or service the unit by a procedure or method not specifically

recommended by the manufacturer, first make sure that such a procedure or method will

not render this equipment unsafe or pose a threat to you and others.

It is the responsibility of the mechanic performing the maintenance or service on a

particular machine to:

!

WARNING

CRUSH AND CUT HAZARD.

Before turning on the equipment, make sure that all personnel

and equipment are clear.

!

WARNING

ELECTROCUTION AND HIGH PRESSURE HAZARDS

Always turn the power off by activating an E-stop when the

equipment is not in operation.

Always verify that all power to the machine has been turned off

and follow approved lockout/tagout safety procedures (OSHA 29

CFR 1910.147) before performing any maintenance on this

equipment.

If it is absolutely necessary to troubleshoot an energized

machine, follow NFPA 70E or the governing regulations at your

location for proper procedures and personal protective

equipment.

The components on this machine can cause severe injury if

adjusted improperly. Follow all procedures in this manual and do

not make adjustments to the machine without guidance from

MiTek or MiTek documentation.

Only trained personnel should make mechanical adjustments to

this machine.

Maintenance

Original Instructions: 001090 rev. C 19

1. Inspect the machine for abnormal wear and damage;

2. Choose a procedure which will not endanger his or her safety, the safety of others,

the equipment, or the safe operation of the machine;

3. Fully inspect and test the machine and the hydraulic, pneumatic and electrical

systems to ensure that the service to the machine has been properly performed and

that the machine, hydraulic, pneumatic and electric systems will function

properly; and

4. Ensure only qualified electricians perform electrical service work.

General Service Rules

1. The design may change or upgrades may occur for any particular component.

Always contact the factory before replacing components.

2. If inspection or testing reveals evidence of abnormal wear or damage to the

machine or if you encounter circumstances not covered in the equipment

manual—STOP—and consult MiTek. The machine must be repaired and serviced

according to the current specifications and procedures of MiTek, using

replacement parts with properties equal to or greater than those specified by

MiTek.

3. Use the correct tools and procedures on this machine, to avoid damage and

incorrect assembly.

4. Always install new gaskets, O-rings, cotter pins, etc., and place Loctite on bolts, if

required.

5. Torque bolts and fasteners to the correct specifications.

6. Clean parts in a nonflammable or high-flash-point solvent only.

7. Lubricate any sliding surfaces before assembly.

8. Many components are manufactured from high carbon, heat-treated steel. Do not

attempt to cold straighten, hot straighten, bend, or weld these components, as they

may fail under load causing serious personal injury or death.

!

WARNING

This machine uses high-voltage electricity, which may cause

serious personal injury or death.

NOTICE

Never use compressed air inside an electrical enclosure. It

may force contaminants into electrical connections.

Use a vacuum to remove dust from electrical enclosures.

Canned air is acceptable after vacuuming.

Maintenance

Original Instructions: 001090 rev. C 20

9. After re-assembly, check all parts for proper installation and operation before

putting the machine back into service.

10. It is beneficial to record all major maintenance and testing. This allows recurring

problems to be predicted and addressed before any production time is lost. Typical

reports and records should include:

• Date

• Serial number of machine

• Description of problems or symptoms

• Corrective action taken

• Parts required

11. MiTek will, from time to time, mail out service bulletins and updates for this

machine. Follow the service bulletins and updates accordingly and file them in

this equipment manual.

Making Adjustments and Replacing Parts

Be careful when making mechanical adjustments. Untrained personnel may damage the

machine or cause harm to themselves and others.

Special materials have been used for some of the components of this equipment. It is

critical to the future performance of this machine that only specified replacement parts are

used. Order all replacement parts through MiTek. Do not substitute parts without first

consulting MiTek to determine if it is safe and effective. No electrical system component,

cable, connector, or device should be modified, removed, disconnected, changed without

specific approval and guidance from MiTek.

!

WARNING

CRUSH AND CUT HAZARDS

Always replace guards after servicing.

Only qualified maintenance personnel shall repair, remove, or

replace guards and safety devices.

NOTICE

Failure to follow the step-by-step procedures in this chapter may

result in incorrect adjustment of this machine.

Only trained maintenance personnel should make mechanical

adjustments to this machine.

Use only the exact replacement parts specified in this manual.

Maintenance

Original Instructions: 001090 rev. C 21

Wearing Personal Protective Equipment

Testing the Safety of the Machine

The test procedure in the Safety section starting on page xv MUST be performed by

qualified personnel after ANY maintenance, adjustment, or modification.

The test should be performed before each shift starts to make sure that the safety features

remain in working order.

Cleaning and Inspecting

Cleaning

If it should become necessary to clean this machine, disconnect it from its power source

first. Do not use liquid cleaners, aerosols, abrasive pads, scouring powders or solvents,

such as benzene or alcohol. Use a soft cloth lightly moistened with a mild detergent

solution. Make sure the surface cleaned is fully dry before reconnecting power.

Use pneumatic air to regularly blow dust and debris off of the tables, ejection components,

and rollers. Make sure truss plates or other sharp objects are clear of all pneumatic and

electrical systems.

!

CAUTION

Follow OSHA guidelines to utilize the proper personal protective

equipment (PPE) while performing maintenance.

The most common include eye protection, hearing protection,

dust masks while blowing off sawdust, gloves while working with

solvents, and fire retardant clothing when troubleshooting an

energized machine.

!

CAUTION

CRUSH AND CUT HAZARD

Always replace guards after completing maintenance and before

removing the lockout/tagout device.

Operating a machine with guards removed may result in serious

injury or death.

NOTICE

Never use compressed air inside of electrical enclosures. It may

force contaminants into electrical connections.

Use a vacuum to remove dust from electrical enclosures. Canned

air is acceptable after vacuuming.

Maintenance

Original Instructions: 001090 rev. C 22

Inspecting the Ejectors

Check the clevis pin in the bell crank and all bolts for wear every three (3) months. Check

bumpers on the high-slope auto-ejectors for wear or damage and replace as needed. See

High Slope Ejector Bumpers for the location of each ejector bumper and replacement

instructions. If bumpers are not replaced, the link arm’s pivot holes will wallow out and

cause premature failure. Replace all other worn parts.

Inspecting the Ejection System as a Whole

Check that the tables are level with the auto-eject rollers on an annual basis.

Pneumatic System Maintenance

The pneumatic system controls the ejectors on the tables and the receiver stands (if

present).

Removing Pressure from the Pneumatic System

Most procedures involving the pneumatic system require the removal of pressure. Use the

following procedure to remove pressure from the system.

1. Prepare the pneumatic system to remove pressure:

a) In systems with foot valves (new models), ensure all shut-off valves are in the

open position.

b) In systems with hand valves, ensure all hand valves are in the neutral position.

2. Push the system shut-off valve on the filter/regulator assembly to the lockout

position so it cuts off air flow. See Figure 5-1.

3. Lockout/tagout through the hole on the yellow slide. See Figure 5-1.

4. Check the air pressure gauge reads 0 psi and actuate an ejector control valve (the

ejectors should not raise) to make sure all pressure has been bled from the system.

!

CAUTION

HIGH PRESSURE HAZARD.

Bleed all pressure from pneumatic lines before performing

maintenance on pneumatic components.

Pressurized components may move suddenly or vent air to

atmosphere, causing injury.

Maintenance

Original Instructions: 001090 rev. C 23

Filter/Regulator

The filter/regulator can be purchased directly from MiTek. Refer to the Parts List chapter

for instructions on ordering parts.

Replacing the Filter Element

The regulator uses a 40-micron filter element that must be replaced every six (6) months.

This filter can be purchased from MiTek. Refer to the Parts List chapter for instructions on

ordering parts.

1. When replacing the filter element,

the system must be free of pressure.

To depressurize the system see

Removing Pressure from the

Pneumatic System.

2. Remove the bowl from the

regulator body by turning it in the

direction indicated by unlock/lock

label while pushing up on the bowl.

Then pull down and remove the

bowl from the body.

3. Unscrew the white end-cap and

remove the old filter element.

4. Install the new filter element and

screw the white end-cap into place.

5. Place the bowl back onto the

regulator body by pushing up and

turning it in the direction indicated

by unlock/lock label. Make sure it

is securely attached before

returning pressure to the lines.

Adjusting the Pressure

The operating pressure of the pneumatic system should be 100 psi. The pressure

adjustment knob shown in Figure 5-1 controls the operating pressure. Do not adjust this