[Type text]

1 | P a g e

Air Force Civil Engineer

Utility Energy Service Contract

(UESC) Playbook

2017

This Playbook is an electronic document. The only valid version is the latest version on the CE Portal. Click here to go to

the CE Portal. Publish Date: 02/20/2018

Air Force Civil Engineer Center

UESC Playbook

2 | P a g e

Table of Contents

Chapter 1 Introduction – Utility Energy Service Contract (UESC) ..................................................................4

Chapter 2 UESC Background, Authority, Financing and Funding ...................................................................5

2.1 Background ..................................................................................................................................................... 5

2.2 Authority ......................................................................................................................................................... 5

2.3 Financing UESCs .............................................................................................................................................. 6

2.3.1 Energy Cost Savings ............................................................................................................................. 6

2.3.2 Guaranteed Savings ............................................................................................................................ 7

2.3.3 Energy Costs ........................................................................................................................................ 7

2.3.4 Maintenance Responsibilities ............................................................................................................. 7

2.3.5 Annual Reconciliation ......................................................................................................................... 7

2.3.6 Buy-down ............................................................................................................................................ 8

2.4 Funding Requirements ................................................................................................................................... 8

2.4.1 Funding UESC Projects ........................................................................................................................ 8

2.4.2 Additional Funding Rules .................................................................................................................... 8

Chapter 3 UESC Roles and Responsibilities ................................................................................................ 10

3.1 AFCEC/CND Roles and Responsibilities ........................................................................................................ 10

3.2 BEM Roles and Responsibilities .................................................................................................................... 10

3.3 CO Roles and Responsibilities ....................................................................................................................... 10

3.4 COTR Roles and Responsibilities................................................................................................................... 11

3.5 Utility Contractor Roles and Responsibilities ............................................................................................... 11

Chapter 4 Types of UESC Contracts ........................................................................................................... 12

4.1 GSA AWC ...................................................................................................................................................... 12

4.2 BOA ............................................................................................................................................................... 13

4.3 Interagency Agreement ................................................................................................................................ 13

4.4. Stand Alone Contract .................................................................................................................................... 13

Chapter 5 UESC Contracting Processes ...................................................................................................... 14

5.1 Installation Contracting Process ................................................................................................................... 14

5.1.1 Phase 1: Project and Acquisition Process......................................................................................... 14

5.1.2 Phase 2: Project Development ......................................................................................................... 16

5.1.3 Phase 3: Final Design and Construction/Installation ....................................................................... 19

5.1.4 Phase 4: Post Project Installation ..................................................................................................... 20

Chapter 6 UESC Business Practices ............................................................................................................ 21

6.1 Baseline Development .................................................................................................................................. 21

6.2 Performance Tests ........................................................................................................................................ 21

6.3 Energy Savings Validation ............................................................................................................................. 22

6.4 Annual Reconciliation Plan (Audit of Savings) .............................................................................................. 23

6.5 Maintenance Related to the TO ................................................................................................................... 23

6.6 Pricing of TO Work ........................................................................................................................................ 23

6.7 Equipment Ownership .................................................................................................................................. 24

Appendix A - Acronym List ........................................................................................................................ 25

Appendix B - References and Master List of Links ....................................................................................... 27

Appendix C - Job Aids ................................................................................................................................ 32

UESC Planning Checklist ................................................................................................................................... 32

Risk/Responsibility Checklist ........................................................................................................................... 34

Appendix D - Guidance .............................................................................................................................. 37

AFCEC Guide to Annual M&V Activities ........................................................................................................... 37

UESC Considerations for the BEM ................................................................................................................... 38

Air Force Civil Engineer Center

UESC Playbook

3 | P a g e

JUSTIFICATION AND APPROVAL ....................................................................................................................... 40

EMSA/MODEL AGREEMENT ............................................................................................................................ 45

Basic Statement of Work (SOW) for the “Letter of Interest” .......................................................................... 62

UESC Task Order (TO) Sample .......................................................................................................................... 63

AFGM 2017-32-01 ............................................................................................................................................ 75

Engineering Technical Letter (ETL) 11-1: Civil Engineer Industrial Control System Information Assurance

Compliance ...................................................................................................................................................... 88

Table of Figures

Figure 1 Procurement Mechanisms ......................................................................................................................... 12

Figure 2 Phase 1: Project and Acquisition Process ................................................................................................. 14

Figure 3 Phase 2: Project Development .................................................................................................................. 16

Figure 4 Phase 3: Final Design and Construction/Installation ................................................................................ 19

Figure 5 Phase 4: Post Project Installation .............................................................................................................. 20

Table of Tables

Table 1 Authority Documents Mandating the AF UESC Program .............................................................................. 5

Air Force Civil Engineer Center

UESC Playbook

4 | P a g e

Chapter 1 Introduction – Utility Energy Service Contract (UESC)

The objective of the UESC Playbook is to provide the parameters and guidance for implementing a

UESC, replacing Engineering Technical Letter (ETL) 12-10: Utility Energy Service Contract (UESC) dated

3 April 2012. This Playbook contains a basic history of the UESC program, primary roles and

responsibilities, step-by-step instructions, job aids, and reference documents to ensure UESC

procedures are followed. This Playbook applies to all Air Force Installations considering using a UESC

including, but not limited to, General Services Administration (GSA), Energy Management Service

Agreements (EMSA), and individual installation contracts. Any deviations require written approval from

the Energy Savings Performance Contract (ESPC)/UESC Program Manager, Air Force Civil Engineer

Center (AFCEC/CND).

Job Aids, resources and reference materials are provided digitally in Links and can be modified as

required by AFCEC/CND.

Limitations: This Playbook does not replace, supersede, or circumvent existing Department of Defense

(DoD) or Air Force (AF) policy.

Applicability: This Playbook is written for the following personnel: AFCEC/CND, Base Civil Engineers

(BCE), Base Energy Managers (BEM), Base Financial Managers (BFM), and installation Contracting

Officers (CO).

Note: Must comply with AFGM2017-32-01, Air Force Guidance Memorandum (AFGM) Civil Engineer

Control Systems Cybersecurity (2 Feb 2017). The AFGM supersedes ETL 11-1, Civil Engineer Industrial

Control System Information Assurance Compliance (30 Mar 2011). However, the AFGM (12 pages)

does not address all items included in ETL 11-1 (32 pages). Therefore, those ETL 11-1 items not

addressed in the AFGM, are still in effect.

Air Force Civil Engineer Center

UESC Playbook

5 | P a g e

Chapter 2 UESC Background, Authority, Financing and Funding

2.1 Background

A UESC is a contract that allows utilities to provide their government customers with energy and

water efficiency improvements and demand-reduction services. UESCs leverage third-party funds

to identify and implement energy conservation measures (ECMs) for a financing term of up to 25

years by statute 10 United States Code (U.S.C.) 2913. AFCEC limits the financing term to the cost

effectiveness of the included ECMs. The AF can use UESCs for all buildings, excluding leased

buildings (unless leased from another Federal agency), where the AF pays the utility bill.

UESCs are typically considered to increase facility energy efficiency through improvements to

installation infrastructure, buildings, and building systems. Under a UESC, a serving or franchised

utility company identifies energy savings strategies that yield an economic return on the

investment. UESCs are used for the following:

1. Reducing energy use

2. Reducing water use

3. Installing high efficiency equipment and/or control systems

4. Re-commissioning or retro-commissioning energy consuming systems

The utility designs and installs the equipment. The capital costs can be paid with appropriated

funds or financed by the utility company. A UESC should be implemented with assurance that the

energy savings can be validated for the term of the UESC and meet the legal intent of the UESC.

Used effectively, a UESC can reduce energy consumption and improve facility infrastructure.

2.2 Authority

The following table lists the Executive Orders (E.O.), directives, and policies that mandate and

support the AF UESC program:

Authority Documents Mandating the AF UESC Program

10 U.S.C. 2911-13, Energy Performance Goals and Plans for Department of Defense

E.O. 13423, Strengthening Federal Environmental, Energy, and Transportation Management (revoked in 2015).

Replaced by: E.O. 13693, Planning for Federal Sustainability in the Next Decade

E.O. 13514, Federal Leadership in Environmental, Energy, and Economic Performance (revoked in 2015). Replaced by: E.O.

13693, Planning for Federal Sustainability in the Next Decade

Public Law (P.L.) 109-58, Energy Policy Act of 2005

10 Code of Federal Regulations (CFR) 436, Federal Energy Management and Planning Programs (10 CFR 436.18-19)

Energy Independence and Security Act (EISA) of 2007

10 U.S.C. 2866, Water Conservation at Military Installations

Air Force Policy Directive (AFPD) 32-10, Installations and Facilities

Table 1 Authority Documents Mandating the AF UESC Program

Air Force Civil Engineer Center

UESC Playbook

6 | P a g e

10 U.S.C. 2913 states that:

1. The Secretary of Defense may authorize the Secretary of a military department having

jurisdiction over a military installation to enter into agreements with gas or electric utilities

to design and implement cost-effective demand and conservation incentive programs

(including energy management services, facilities alterations, and the installation and

maintenance of energy saving devices and technologies by the utilities) to address the

requirements and circumstances of the installation.

2. If an agreement under this subsection provides for a utility to advance financing costs for

the design or implementation of a program referred to in that paragraph to be repaid by the

United States, the cost of such advance may be recovered by the utility under terms no less

favorable than those applicable to its most favored customer.

3. Subject to the availability of appropriations, repayment of costs advanced under paragraph

(2) shall be made from funds available to a military department for the purchase of utility

services.

4. An agreement under this subsection shall provide that title to any energy-saving device or

technology installed at a military installation pursuant to the agreement vest in the United

States. Such title may vest at such time during the term of the agreement, or upon

expiration of the agreement, as determined to be in the best interests of the United States.

2.3 Financing UESCs

UESC projects, funded or financed, must produce financial savings that are equal to or greater

than the cost of implementation, including the cost of financing. All UESC costs, including mid-

contract replacement of capital equipment, must be funded out of the UESC savings they

generate, unless funded using appropriated funds. An installation's post-UESC utility costs, such

as energy and Operations and Maintenance (O&M), plus the cost of the UESC project cannot

exceed the utility costs prior to the implementation of the UESC project. If the project is financed,

the energy cost savings are used to pay the utility.

2.3.1 Energy Cost Savings

Energy cost savings are annual recurring savings, including:

1. Recurring reductions in expenses (other than energy costs) related to energy-

consuming equipment, including costs associated with waste disposal.

2. One-time energy-related cost savings resulting from avoided expenditures because

of the UESC project.

3. Demand-related savings, such as peak shaving.

4. One-time utility rebates.

The utility contractor is responsible for the design, acquisition, installation, and

measurement and verification (M&V) of the project equipment or systems that produce

the savings is required. Refer to 2.3.5 Annual Reconciliation for more information. Refer

to the GSA Utility Contractors List to view approved contractors.

Air Force Civil Engineer Center

UESC Playbook

7 | P a g e

Certain risks are associated with implementing a UESC for the AF. It is essential the AF

does not assume any of the utility contractor’s risk, such as ECM performance. AF risks

include utility rates and mission changes.

Refer to the Risk/Responsibility Checklist job aid for guidance.

2.3.2 Guaranteed Savings

There are no guaranteed savings in a UESC contract. The equipment installed is

guaranteed to perform for one year and provisions shall be made for the labor, supplies,

parts, and materials to maintain the Energy Conservation Project (ECP) for the term of the

Task Order (TO). However, annual verification of energy savings must be accomplished.

This requirement includes an approved M&V plan (see 2.3.5).

As an exception, guaranteed savings can be negotiated into a TO if the local utility provider

offers it. If part of the TO, the utility company provides a guarantee of savings to the AF

and establishes payment schedules reflecting the guarantee.

The payment to the utility is based on an agreed upon percentage of the calculated

savings. These awarded TOs, like utility bills, are “must-pay” requirements and are

programmed into the annual utility budget process. Refer to 42 U.S.C. 8287, Section

801(a)(2)(A).

2.3.3 Energy Costs

Annual payments by the AF under a UESC cannot exceed the value of energy and O&M

savings relative to costs prior to the UESC. Refer to 42 U.S.C. 8287; Section 801(a)(2)(B).

Forecasted energy costs and the discount rate (present value of future cash flows) are

major factors in determining UESC savings. 10 CFR 436, Federal Energy Management and

Planning Programs, provides detailed instructions for UESCs, including the calculation of

life cycle costs. For example, 10 CFR 436.14 mandates the use of the annual supplement to

Life Cycle Costing Manual for the Federal Energy Management Program (National Institute

of Standards and Technology [NIST] 85-3273) to determine the discount rate and

forecasted energy costs. UESCs must use the NIST-published "implied long-term average

rate of inflation" with the appropriate regional fuel price indices. AF installations are

considered “industrial” for the purpose of calculating the NIST utility escalation rate. The

provisions in 10 CFR 436.14 are mandatory and failure to comply results in the contract

being found legally insufficient.

2.3.4 Maintenance Responsibilities

The installation is responsible for TO-required maintenance and repair. Maintenance and

repair are critical to sustain an ECM’s performance throughout the life of the TO. Ensure

provisions are made for the labor, supplies, parts, and materials to maintain the ECP for the

term of the TO. Refer to section 6.5 Maintenance Related to the TO for more information.

2.3.5 Annual Reconciliation

An annual reconciliation is required for a UESC. A verification of energy savings

reconciliation must be accomplished for each awarded TO annually. This requirement

includes an approved M&V plan using at a minimum the current International Performance

Measurement and Verification Protocol (IPMVP) at the time the TO is awarded. Measured

Air Force Civil Engineer Center

UESC Playbook

8 | P a g e

savings are required when using options B or option C metered savings, where a minimum

of one third savings are measured. During the annual reconciliation, the utility contractor

confirms the adequacy of maintenance. Refer to paragraph (a)(2)(A) of 42 U.S.C. 8287.

The BEM validates the utility company’s annual reconciliation follows the agreed upon

M&V plan.

2.3.6 Buy-down

UESC costs may be funded with installation funds used to buy down part of the TO, such as

end-of-year fallout funds. These one-time funds can be identified in the payment schedule

to the utility company upon acceptance of the ECM and commencement of the

performance period. This allows for a lower financed amount and shorter term, thereby

reducing interest costs over the term. Buy-down schedules are recommended for projects

with payment periods greater than 5 years. If, after award, O&M funds are used to buy

down a portion of the TO, several steps are necessary:

1. Use of these funds must be identified as soon as possible to the utility company.

2. Economics must be considered.

3. Prepayment penalties must be identified by the utility company.

2.4 Funding Requirements

2.4.1 Funding UESC Projects

Title 10 USC § 2913(d)(3) specifies that repayment of financed costs be made from funds

available to a military department for the purchase of utility services. UESC savings must be

real and verifiable so the installation doesn’t run the risk of a savings shortfall. Work that

encompasses O&M-type savings or other savings that do not eliminate actual costs or

produce actual savings versus avoided costs should not be included. Civilian personnel costs

are not allowed unless positions are deleted from manpower documents.

Use caution if applying anticipated cost avoidance to the UESC due to major

repair/replacement that may not be needed because of the UESC. Historical data may not be

able to back up expenditures, but the costs may be justified as a future expense; for

example, as an engineering analysis or as life cycle predictions. If these major expenditures

are included as captured savings, they become a “must-pay” bill from O&M funds. Before

these funds are included in a UESC, the installation and AFCEC/CND must agree to the

funding source and create a record of decision to justify the action and agreement.

2.4.2 Additional Funding Rules

Facilities under a UESC may require a buyout before non-UESC work is performed.

Government actions (post award) on a building that will impact, alter, or dismantle UESC

material or equipment, rendering that part of the UESC contract invalid, should buyout the

applicable portion of the contract. Examples include demolition, upgrades, construction

and privatization.

When possible, buyout funds should be programmed with the same fund source as the

project itself. Any demolition, upgrades, construction, or privatization shall be identified to

the CO for evaluating and determining appropriate contract action.

Air Force Civil Engineer Center

UESC Playbook

9 | P a g e

The following additional funding rules apply:

1. Military Construction (MILCON) funds cannot be applied to a UESC. MILCON

projects cannot be accomplished under a UESC. Use of MILCON funds for a

purpose outside appropriated use would result in a violation of the Purpose Act (31

U.S.C. 1301).

2. Non-appropriated Fund (NAF) functions may be authorized to use appropriated

O&M funds. NAF Category C ECPs must use savings only from other NAF ECPs to

avoid subsidizing or being subsidized by funds other than NAF-funded sources. All

actions affecting funding must be coordinated with the NAF funds manager.

3. Military Family Housing (MFH) funds are appropriated separately and used

specifically for MFH purposes. MFH ECPs must use savings only from other MFH

ECPs to avoid subsidizing or being subsidized by funds other than MFH-funded

sources. Use of MFH funds for a purpose outside their appropriated use would

result in a violation of the Purpose Act (31 U.S.C. 1301).

4. Reimbursable customers require separate accounting procedures to ensure that

adequate payments are being applied to their accounts. Reimbursable customers

must agree to a memorandum of agreement or equal to provide payments for the

term of the contract.

Air Force Civil Engineer Center

UESC Playbook

10 | P a g e

Chapter 3 UESC Roles and Responsibilities

This chapter provides an in-depth explanation of the roles and responsibilities associated with the UESC

process.

3.1 AFCEC/CND Roles and Responsibilities

a. Serves as the UESC Program Management Office (PMO) and centrally manages all UESCs.

Provides initial vetting, approves each stage of project development, manages the

evaluation process, and assists installations in the development of the UESC project through

completion of the TO term. Provides technical review and approval of all UESC projects.

b. Coordinates and supports the contracting office, as needed.

c. Develops UESC procedures/guidance and provides UESC training to appropriate installation

personnel, following the Department of Energy (DoE) Federal Energy Management Program

(FEMP) UESC guidelines.

d. Acts as the center of expertise for UESC contracts. Provides tools and expertise to assist in

implementing a UESC. Acts as a clearinghouse for UESC lessons learned.

e. Maintains oversight and compliance with AF policies and interprets guidance for the

installation’s UESC program.

3.2 BEM Roles and Responsibilities

a. The Defense Logistics Agency-Energy (DLA-Energy) is the execution contracting office for all

AF UESC Projects. Installation BCE and the local CO may submit a waiver request to

AFCEC/CND PMO to execute locally. AFCEC, in conjunction with the installation makes the

final determination for the office of execution.

b. Works with the CO to implement the UESC program. Compiles and provides required

project documentation, including site data packages and evaluation criteria to the CO.

Performs an analysis on all construction costs and provides a statement to the CO that all

costs are realistic for the work performed. Refer to Considerations for the BEM for more

information.

c. Completes UESC training before implementing a UESC program and ensures that assigned

personnel associated with the UESC program receive this training for the term of the UESC.

d. Assists the CO in ensuring the utility company complies with all requirements for the term

of the TO.

e. Determines if other funding sources such as Sustainment, Restoration and Modernization

(SRM) and the Energy Conservation Investment Program (ECIP) are available and more cost-

effective.

f. Ensures the CO is notified of mission changes, facility modifications, or demolition.

3.3 CO Roles and Responsibilities

a. Overall responsibility to ensure that ESPC projects serve the best interests of the AF and are

consistent with the terms and conditions of the ESPC contracts, legislation, and regulations.

Air Force Civil Engineer Center

UESC Playbook

11 | P a g e

b. Awards and administers all issued UESC TOs following AFCEC/CND technical review and

approval.

c. Assembles the UESC team and serves as chairperson for all meetings with the utility

company.

d. Evaluates and documents mission changes, facility modifications, and demolition for

appropriate contract action.

e. Appoints a Contracting Officer Technical Representative (COTR) to act as a liaison between

the utility contractor and the CO.

f. Provides the total contract cost for each phase of a UESC and a final signed copy of the TO

to AFCEC/CND.

3.4 COTR Roles and Responsibilities

a. Acts as technical representative for CO.

b. Identifies and supports project goals and development efforts.

c. Reviews all deliverables.

d. Provides oversight during construction and installation.

e. Reviews and approves technical aspects of the annual M&V reports, when applicable.

3.5 Utility Contractor Roles and Responsibilities

a. Develops and submits a Preliminary Assessment (PA) and Feasibility Study (FS).

b. Documents the baseline data and ensures the data adequately supports the baseline.

Simulation models are not acceptable baselining tools.

c. Provides funding for energy reduction project(s).

d. Implements the UESC project, including purchasing equipment, installing equipment, and

overseeing and completing construction during projects.

e. Performs metering and data collection to ensure energy reduction and provides the M&V

report.

Air Force Civil Engineer Center

UESC Playbook

12 | P a g e

Chapter 4 Types of UESC Contracts

The AF has several types of UESC contracts available to them, including, GSA Area-wide Contracts

(AWCs), Interagency Agreements and EMSAs. Basic Ordering Agreements (BOA) are not contracts, but

establish general terms and conditions for future TO or Delivery Order (DO). Agencies not covered by

such agreements may enter contracts with their servicing utility. If an AWC exists with a utility,

AFCEC/CND must approve the use of other procurement mechanisms. EMSAs serve as a template for

agencies to use in establishing UESC’s or as a Master Agreement Exhibit “C” within an AWC, EMSAs can

be used as a standalone contracting vehicle.

4.1 GSA AWC

Utility services can include electricity, natural or manufactured gas, water, sewage, thermal

energy, chilled water, steam, hot water, and high-temperature hot water. AWCs outline general

terms and conditions and authorize any agency in a utility’s franchised service territory to place

TOs for utility services and utility energy services offered under the contract. Refer to the GSA

Utility Contractors list to view the servicing area utility contractors.

The GSA has numerous active utility AWCs to procure energy, water, and renewable energy

systems projects. Installations develop an EMSA, which is provided as an attachment to the

existing GSA AWC. If more than one utility company can offer energy management services the

AF provides a fair opportunity and selects the one that provides the best value. If only one utility

is available, the CO prepares a justification and approval (J&A), prior to having negotiations that

lead to an award without full and open competition Federal Acquisition Regulations (FAR)

6.302.5. Refer to the Justification and Approval for Other Than Full and Open Competition sample

document.

Note: Financing is an option for Federal facilities.

GSA AWC contracts are

within a utility provider’s

service territory.

BOAs are used when

there is not an AWC.

BOAs contain terms,

conditions, and services

for future delivery orders.

EMSAs are used in

establishing UESCs. They

can be a Master

Agreement Exhibit “C”

within an AWC, BOA or as

a stand-alone agreement.

Figure 1 Procurement Mechanisms

Air Force Civil Engineer Center

UESC Playbook

13 | P a g e

4.2 BOA

A BOA is an agreement between the utility and the installation to establish general terms and

conditions that are incorporated into future firm fixed-price TOs and may be used when an AWC

does not exist. A federal agency can establish a BOA with their utility when specific items,

quantities, and prices are not known, but a substantial number of requirements are anticipated

and there is potential for more than one UESC TO. A TO placed under a BOA constitutes the

contract and details the services to be delivered.

A BOA does not guarantee future TOs to the utility and is not used to restrict competition if more

than one utility supports an installation. The agreement is reviewed annually and revised, as

necessary, to meet the requirements of the FAR 16.703. A modification to the agreement itself

does not retroactively affect any individual TOs issued under it.

The CO establishes the BOA with the utility employing normal contracting procedures in

accordance with FAR 16.703, DFARS 216.703, and Procedures, Guidance and Information (PGI)

217.703(d).

4.3 Interagency Agreement

Bonneville Power Administration (BPA) – Provides energy management services to their

customers within their service territory.

4.4. Stand Alone Contract

For installations where the utility does not have an AWC, an EMSA may be used as a template for

terms and conditions and award is made to the utility under the authority of 10 U.S.C. 2913.

Air Force Civil Engineer Center

UESC Playbook

14 | P a g e

Chapter 5 UESC Contracting Processes

5.1 Installation Contracting Process

5.1.1 Phase 1: Project and Acquisition Process

Figure 2 Phase 1: Project and Acquisition Process

Steps 1 & 2: Installation leadership decides to conduct a UESC project and requests

AFCEC/CND approval.

Prior to engaging with a utility, the CO and the BEM/BCE prepare a summary of the type of

ECMs being considered and relevant baseline information and submits them to AFCEC/CND

for initial vetting. AFCEC/CND works with the CO and BEM/BCE to determine if the UESC is

an appropriate choice for execution. Note: AFCEC serves as advisor through project life.

Refer to the UESC Planning Checklist job aid for guidance.

Steps 3 & 4: The CO develops the Statement of Work (SOW) and the acquisition strategy.

DLA-Energy is the execution contracting office for all AF UESC projects.

The CO and BEM review the utility agreement (AWC) to ensure it allows for energy and

demand-side management services. Refer to Considerations for the BEM for guidance on

implementing a successful UESC. The Energy Team is assembled and a date and time is

coordinated for an on-site meeting or teleconference with AFCEC/CND to explore potential

opportunities, develop the UESC criteria, and determine the acquisition strategy. The

Energy Team ensures the UESC contract adheres to appropriate, and confirms the scope

and pricing of the project are in the best interest of the AF. The key activities of an

acquisition strategy are:

1. Developing a clear scope with schedule.

2. Planning a sound and equitable business arrangement.

3. Managing risk of concurrent development/production.

4. Planning to support installed systems/equipment.

5. Ensuring competition.

6. Obtaining resources to award and administer the contract.

7. Developing the SOW. For an example, refer to the Sample SOW.

Air Force Civil Engineer Center

UESC Playbook

15 | P a g e

Steps 5 & 6: The CO sends a “Letter of Interest” to each eligible utility and provides each

utility with a fair opportunity to be considered.

The CO contacts each serving utility to determine interest in providing a UESC. The letter

should:

1. Clarify agency intention to use UESC to meet energy goals.

2. Describe the initial project scope.

3. Inform the serving utilities of the opportunity for consideration to all.

4. Provide evaluation method and criteria.

Refer to the GSA Utility Contractors list to view the servicing area utility contractors.

Step 7: The CO drafts the initial J&A.

The J&A is to be executed prior to negotiations leading to TO award without full and open

competition. J&As use guidance provided in the following regulations:

1. FAR 6.302‐5

2. 10 USC 2304(c)(5)

3. Competition in Contracting Act (CICA)

J&As are initiated during acquisition planning and establishes the contractor meets the

definition of a utility. The J&A describes services offered by the utility and why

performance by the utility is required, indicating the agreement will be cost effective, fair,

and reasonable. J&As are finalized before awarding the TO.

Refer to the Justification and Approval for Other Than Full and Open Competition form for

an example.

Note: If more than one utility company can offer energy management services, all must be

provided a fair opportunity to participate and select the one that provides the best value;

no J&A required. However, if only one utility is available, the CO must prepare a J&A prior

to negotiations, leading to an award without full and open competition.

Steps 8 & 9: The CO notifies the servicing utilities of the selection results.

In selecting a utility, the following evaluation factors may be used:

1. Is this a multi‐year project with multiple TOs or will this have a single TO?

2. What experience does the utility have doing UESC projects?

3. What types of projects has the utility done in the past?

a. How complex were previous projects compared to current project?

b. What was the size and scope of the previous projects?

c. How was their past performance?

d. What are their staff qualifications?

Air Force Civil Engineer Center

UESC Playbook

16 | P a g e

4. Is their pricing clear?

a. Do they provide an explanation of fees and markups?

b. Do they provide expectation of payment and cost recovery for assessments?

c. Do they have the ability to secure financing at reasonable terms?

5. What is the AF’s history and experience with the utility?

5.1.2 Phase 2: Project Development

Step 10: The CO requests a PA from the utility and evaluates the utility’s response.

The PA is a high-level assessment that:

1. Provides a baseline for existing conditions.

2. Identifies potential water and energy efficiency and renewable energy

opportunities.

3. Estimates the cost to implement the opportunities.

The CO develops a Master Agreement Exhibit “C”, checks the appropriate box and provides

details of specific base requirements. The Master Agreement Exhibit “C” must be signed by

the utility representative and CO. Typically, a PA is at no cost to the government. If there

is a cost to the government, the cost should be negotiated with the utility and included in

the Master Agreement Exhibit “C”.

Note: If a long-term project or multiple projects are anticipated, use the EMSA. The EMSA

is a template for developing a Master Agreement Exhibit “C” and contains terms and

conditions essential to a UESC. It can be used to issue single or multiple TOs for the four

phases:

1. Preliminary Audit

2. Feasibility Study

3. Engineering/Design

4. Construction/Implementation

If the EMSA is not used, each phase will have a separate Master Agreement Exhibit “C”.

Figure 3 Phase 2: Project Development

Air Force Civil Engineer Center

UESC Playbook

17 | P a g e

Once the utility completes the PA and delivers a proposal, the Energy Team reviews the

proposal and provides written comments to the CO. A government-only meeting and/or

teleconference is held to discuss the comments and determine if recommended measures

will be pursued in a FS. The CO ensures all parties have reviewed the proposal. Once

AFCEC/CND approves, the CO prepares authorization for the utility to begin an FS.

Note: If the government decides to terminate at this point and the PA costs were

negotiated, the CO documents the decision and provides an invoice to pay the utility.

Step 11: The CO requests the FS and evaluates the utility’s response.

Unless the EMSA was used at the PA, the CO develops a Master Agreement Exhibit “C” and

checks the appropriate box for the FS. The CO clarifies the ECMs from the PA to be

included and negotiates the development cost of the FS prior to obtaining signatures. If

financing, the cost is rolled into the next phase. The CO may require that the development

cost of the FS be obligated before proceeding to that step.

The FS is a detailed analysis that:

1. Identifies and describes a technically viable and cost-effective project scope.

2. Develops a baseline of energy and water consumption, equipment inventory and

conditions, and operational schedules.

3. Provides a plan for training, O&M, and performance assurance.

4. Provides a project design sufficient to support a firm-fixed price for design and

implementation (D&I).

The utility should provide a detailed, open‐book cost estimate with the FS.

Note: The FS is commonly referred to as an “Investment Grade Audit” (IGA).

The utility completes an in-depth FS of the selected ECMs and delivers a feasibility proposal

to the Energy Team. The Energy Team reviews the proposal and provides written

comments to the CO to consolidate. Prior to sending comments to the utility, a

government-only meeting and/or teleconference is held to discuss the consolidated

comments and determine if recommended measures will advance to the

Engineering/Design phase. The CO ensures all parties have reviewed the proposal. Once

AFCEC/CND approves, the CO prepares authorization for the utility to begin an

engineering/design study.

Note: If the government decides to terminate the FS at this point, the CO documents the

decision and provides invoice to pay the negotiated FS costs.

Note: If the installation requests to cancel the project after the completion of the FS, the

installation must provide a letter of cancellation to the AFCEC/CND Program Manager on

the installations letterhead detailing the reason for the requested termination of the

project. The letter is required to be signed by the BCE and can be transmitted

electronically.

Steps 12 & 13: The CO submits a firm-fixed price Request for Proposal (RFP) for design

and Energy Team evaluates the utility’s proposal.

Air Force Civil Engineer Center

UESC Playbook

18 | P a g e

The CO sends a letter requesting a firm‐fixed price for D&I. The utility responds with the

following information:

1. A letter showing the firm‐fixed price offer.

2. An updated design schedule.

3. An updated installation schedule.

4. Finalized financing terms.

Step 14: The installation CO finalizes the J&A.

Refer to the Justification and Approval for Other Than Full and Open Competition form for

an example.

Step 15: The installation CO issues the Award of Task Order for design and

implementation.

The award letter:

1. States the TO executes a contract under the AWC.

2. Provides authorization to proceed with the project.

3. Lists attachments, which include:

a. Scope of work, specifications, and performance standards.

b. Terms and conditions.

c. Agency‐specific clauses not in AWC or Master Agreement Exhibit “C”.

d. Templates for invoicing, price schedule and termination schedule.

4. Requests confirmation or update of schedule for D&I.

5. Sets time and location for kick‐off meeting.

6. Provides name and contact information of the CO and the COTR.

Refer to the Task Order Sample for an example TO.

UESCs are subject to the requirements of part 17.1 of the FAR, which requires federal agencies

to notify Congress at least 30 days prior to the award of certain proposed multiyear contracts.

FAR part 17.1 establishes the Congressional notification requirement for multiyear contracts

that include a cancellation ceiling in excess of $125 million. See 48 C.F.R. § 17.108(b). The

Congressional notification requirement need not be burdensome or result in undue delay.

Notification can be provided when a reasonable estimate of the underlying project’s

cancellation ceiling is obtained, which generally occurs well in advance of contract award.

Such early notification may also be provided on a periodic basis (e.g., semiannually, quarterly,

etc.) and for multiple UESCs.

Air Force Civil Engineer Center

UESC Playbook

19 | P a g e

5.1.3 Phase 3: Final Design and Construction/Installation

Figure 4 Phase 3: Final Design and Construction/Installation

Step 16: The utility submits engineering designs and the CO reviews/approves.

The CO develops the Master Agreement Exhibit “C” and checks the appropriate box for ECP

Engineering/Design Study and clarifies the ECMs from the FS proposal. The CO directs the

use of all appropriate AF design and construction standards and negotiates the

development cost for engineering/design prior to obtaining signatures. If financing, the

development costs are rolled into the TO.

The utility provides the final design, plans, and specifications with detailed pricing

consistent with the FS and provides a final proposal to the Energy Team. The Energy Team

reviews the final proposal and provides written comments to the CO to consolidate. Prior

to sending comments to the utility, a government-only meeting and/or teleconference is

held to discuss consolidated comments and determine if recommended measures will

progress to the construction/installation phase. The utility addresses the consolidated

comments. The Energy Team reviews the comments and determines if a TO should be

issued for the construction phase. The CO negotiates any revisions and prepares internal

documentation required prior to award.

The utility submits a final proposal with all negotiated changes and the final financing

schedule. Once internal approval is obtained, the CO awards the TO and provides copies to

AFCEC/CND. The CO provides a copy of the TO award with the executed Master

Agreement Exhibit “C” to the GSA regional office within 30 days after execution.

Steps 17 & 18: The utility constructs/installs the ECMs and the installation CO and COTR

provides oversight. The utility provides O&M training, performance assurance,

commissioning, etc.

During construction/installation, AF oversight is critical. Due diligence requires the AF to

trust and verify to ensure the installed ECMs meet design and performance requirements.

The utility begins construction/installation in accordance with (IAW) the TO. Once the utility

performs the work, prior to government acceptance, the utility will provide:

1. ECM training

2. O&M manuals

3. As-built drawings/specifications

4. Testing of each ECM IAW the commissioning plan.

The BEM or COTR witnesses the utility’s commissioning activities.

Air Force Civil Engineer Center

UESC Playbook

20 | P a g e

Note: If no award is made, the CO documents the decision and provides an invoice to pay

the negotiated engineering/design costs.

Steps 19 & 20: The CO accepts the ECM projects and reports project details to FEMP and

GSA.

After all of the ECMs are installed, tested, and commissioned and all deliverables are

received, the CO signs a Certificate of Completion that includes a checklist and statement

allowing payments to begin.

5.1.4 Phase 4: Post Project Installation

Figure 5 Phase 4: Post Project Installation

Step 21: The CO submits invoices & payments.

Timely payment to the utility is critical. Payment frequency is defined in the TO. Invoices

can be paid as part of the utility bill. Payments should be made using proper accounting,

budgeting, and invoicing procedures.

Step 22: The utility provides services (such as performance assurance, etc.) per the TO.

The performance assurance plan prescribes the post‐acceptance activities, i.e., AF

responsibilities and utility responsibilities.

Reporting should be done IAW the performance assurance plan and FEMP/GSA

guidelines. GSA and FEMP must be notified of the TO award. The notification includes:

1. Report on the use of AWC and service agreements including the Authorization

for Energy Management Services.

2. FEMP UESC Data Collection.

3. Annual Agency reports include UESC project information.

Step 23: The installation closes out the contract at the end of the TO.

Note: AFCEC/CND reserves the right to use the Defense Logistics Agency-Energy (DLA-

Energy) as the contracting office for UESC projects.

Air Force Civil Engineer Center

UESC Playbook

21 | P a g e

Chapter 6 UESC Business Practices

The following business practices help the installation implement a UESC, translate the legislative

requirements, and apply the lessons learned to achieve a successful ECM. Each TO includes mutually

agreed upon procedures defining how to verify ECM performance post-installation.

6.1 Baseline Development

An energy baseline is the amount of energy that would have been used if no energy conservation

equipment had been installed. The utility contractor must clearly document the baseline data.

M&V is part of a UESC contract, metering and data collection are performed by the utility

contractor and verified by the installation to ensure the baseline reflects realistic energy

consumption upon which the savings calculations are based. Data collection requirements vary

by ECP and M&V method, but metered data is required for weather-impacted ECPs. Existing

meters should be used as much as possible to collect this data. The M&V plan must be

measurement-based. If the utility contractor and AFCEC/CND determine that model by

simulation is the only valid methodology, the models must be validated/calibrated by the utility

contractor and verified by installation personnel. Refer to the AFCEC Guide to M&V Activities for

more information on M&V requirements.

Note: It is important that equipment controlled by ambient temperature devices have valid

measurements. Savings validation and future baseline adjustments will require this data before

modifications can be applied to the existing baseline.

All assumptions made in the preliminary audit should be validated in the FS by the utility

contractor. Validation includes documenting all pertinent data and formulas used to compute the

energy savings so the BEM can easily explain these savings in the future. AFCEC/CND review and

endorsement of the baseline is required.

6.2 Performance Tests

A performance test is a process for achieving, verifying, and documenting the performance of

equipment installed or modified as part of an ECP. This process begins in the FS phase with the

development and approval of a performance test plan that is implemented after the TO award.

Performance tests are completed post construction to certify that all equipment is functioning

and operating properly. The results are approved by AFCEC/CND before conducting the energy

savings verification tests.

A performance test plan is developed as part of the FS phase and is prepared for each ECP. The

performance test plan describes all aspects of the test process, including:

1. Schedules

2. Responsibilities

3. Documentation requirements

4. Functional performance test requirements

The functional performance tests describe:

1. The conditions or loads the tests are performed.

Air Force Civil Engineer Center

UESC Playbook

22 | P a g e

2. The location of test sensors.

3. The frequency of measurements.

4. The type of test equipment.

5. The test methods.

6. The acceptable range of results.

The level of detail depends on the complexity of the ECP. The performance test plan is detailed

enough so the installation knows exactly what tests will be performed, prior to signing the TO

award.

The final acceptance report is submitted after all functional performance tests are completed.

The final acceptance report is submitted for approval in writing to the CO and BEM. The final

acceptance report includes:

1. The executive summary.

2. ECP descriptions.

3. The performance plan.

4. Test results.

The CO approves the performance test results after coordination and verification of results by the

BEM.

6.3 Energy Savings Validation

A formal set of test procedures with the acceptable range of results are developed to validate

energy savings. These test procedures are submitted by the utility contractor during the FS and

approved before awarding the TO. The test procedures describe:

1. The conditions or loads for the tests being performed.

2. The location of test sensors.

3. The frequency of measurements.

4. The type of test equipment used.

5. Test methods.

6. The acceptable range of test results.

The test procedures shall verify all energy savings intended under the ECP/ECM.

After the BEM/CO approves the performance test results for each ECP, the utility contractor

performs the approved energy savings test procedures to validate the energy savings for each

ECP.

Once the validated energy savings have been approved for all ECPs, the utility contractor submits

an invoice for payment the first full month after acceptance of the ECM.

Air Force Civil Engineer Center

UESC Playbook

23 | P a g e

6.4 Annual Reconciliation Plan (Audit of Savings)

Each ECM in the TO has, at a minimum, a detailed annual reconciliation plan approved before the

TO award. The plan describes:

1. A formal set of test procedures.

2. An acceptable range of results.

3. A schedule of how reconciliation payments will be assessed if savings fall below the

guarantee.

4. A certification by the utility that all O&M requirements and conditions have been met for

each ECP in the TO.

The procedures should be similar to those developed to validate energy savings. The purpose is

to test, validate, and document the energy savings. The CO must approve the annual

reconciliation of savings after coordination and verification of savings by the BEM.

6.5 Maintenance Related to the TO

Maintenance is the responsibility of the BCE. Similar to a construction contract, the Utility is

responsible for a 1-year warranty period, unless other conditions are negotiated. Refer to section

2.3.4 Maintenance Responsibilities for more information.

6.6 Pricing of TO Work

The BEM/CO requests that the utility company provide detailed documentation needed to

determine the reasonableness of the price. Utility company estimates for each ECP identify all

major costs, including:

a. Equipment

b. Labor

c. Design

d. Maintenance

e. Repair

f. Parts

g. Overhead and profit

h. Travel

i. M&V, as required in the ECP

The government prepares an independent government estimate (IGE).

Ancillary savings are any savings attributable to the project other than energy savings, such as

manpower, materials, or eliminating contract-operated functions. Maintenance, repair, or

operations costs for tasks currently being performed by the government or government

contractor are ancillary savings if the utility:

1. Assumes the tasks

2. Reduces the tasks

3. Eliminates the tasks.

Air Force Civil Engineer Center

UESC Playbook

24 | P a g e

Savings must be real and verifiable. The BEM determines whether a utility-proposed task

elimination or reduction would be considered an ancillary savings available for sharing. The AF

provides the dollar value of the ancillary savings.

Government civilian positions must be deleted from the official manpower rosters before related

savings are added to the UESC proposal. The BEM/CO must work the request through

AFCEC/CND and Air Staff so the funds can be reprogrammed to the UESC account. A provision is

included in the package to capture the lost manning in at least one Program Objective

Memorandum (POM) cycle prior to the end of the UESC TO.

Note: O&M funds may need to be expended to pay the utility until the reprogramming action is

completed.

The final negotiated savings shall be applied to the UESC contract. The cost of elimination

contract-operated functions are not negotiated until after TO award. These costs are estimated

and added into the TO.

6.7 Equipment Ownership

Generally, the AF owns the equipment post-construction and must update real property records

to show ownership of the utility installed equipment. The utility is required to provide to the AF,

prior to contract completion, O&M manuals, maintenance training, and the Material Inspection

and Receiving Report (DD-250 Form). However, due to taxes and/or rebates, occasionally the

utility retains ownership post-construction. In either case, the ownership determination is

defined and agreed upon within the TO.

Air Force Civil Engineer Center

UESC Playbook

25 | P a g e

Appendix A - Acronym List

Acronym

Definition

AF

Air Force

AFCEC/CND

Air Force Civil Engineer Center, Energy Program Development Division

AFPD

Air Force Policy Directive

AWC

Area-wide Contract

BCE

Base Civil Engineer

BEM

Base Energy Manager

BFM

Base Financial Managers

BOA

Basic Ordering Agreements

BPA

Bonneville Power Administration

CE

Civil Engineer

CFR

Code of Federal Regulations

CICA

Competition in Contracting Act

CO

Contracting Officer

COTR

Contracting Officer Technical Representative

D&I

Design and Implementation

DLA

Defense Logistics Agency

DO

Delivery Order

DoD

Department of Defense

DoE

Department of Energy

ECIP

Energy Conservation Investment Program

ECM

Energy Conservation Measure

ECP

Energy Conservation Project

EISA

Energy Independence and Security Act

EMSA

Energy Management Service Contract

EO

Executive Order

ESCO

Energy Services Company

ES&H

Environmental, Safety & Health

ESPC

Energy Savings Performance Contract

ETL

Engineering Technical Letter

FAR

Federal Acquisition Regulation

FEMP

Federal Energy Management Program

FFP

Firm Fixed Price

FIO

Facilities Improvements Office

FS

Feasibility Study

GHG

Greenhouse Gas

GSA

General Services Administration

HAZMAT

Hazardous Material

HMI

Human Machine Interface

IAW

In Accordance With

IES

Illuminating Engineering Society

IGA

Investment Grade Audit

IGE

Independent Government Estimate

IPMVP

International Performance Measurement and Verification Protocol

J&A

Justification and Approval

JB

Joint Base

M&O

Maintenance and Operations

M&V

Measurement and Verification

MFH

Military Family Housing

MILCON

Military Construction

NAF

Non-appropriated Fund

NIST

National Institute of Standards and Technology

O&M

Operations and Maintenance

Air Force Civil Engineer Center

UESC Playbook

26 | P a g e

Acronym

Definition

ODC

Ozone Depleting

ORCA

Online Representation and Certifications Application

OSHA

Occupational Safety and Health Administration

PA

Preliminary Assessment

PGI

Procedures, Guidance and Information

P.L.

Public Law

PLC

Programmable Logic Controller

PMO

Project Management Office

POM

Program Objective Memorandum

QAE

Quality Assurance Evaluator

RFP

Request for Proposal

SOW

Statement of Work

SRM

Sustainment, Restoration and Modernization

TO

Task Order

U.S.C.

United States Code

UESC

Utility Energy Service Contracts

Air Force Civil Engineer Center

UESC Playbook

27 | P a g e

Appendix B - References and Master List of Links

Section

Type

Name of Item

Linked

Link

Chapter 2, 4,

Justification and

Approval for

Other Than Full

and Open

Competition

External

10 U.S.C. 2913

https://www.gpo.gov/fdsys/pkg/USCODE-2010-title10/pdf/USCODE-2010-

title10-subtitleA-partIV-chap173-subchapI-sec2913.pdf

Chapter 2

External

10 United States

Code (U.S.C.) 2911-

13, Energy

Performance Goals

and Plans for

Department of

Defense

https://www.gpo.gov/fdsys/granule/USCODE-2010-title10/USCODE-2010-

title10-subtitleA-partIV-chap173-subchapI-sec2911

Chapter 2

External

E.O. 13423,

Strengthening

Federal

Environmental,

Energy, and

Transportation

Management

https://www.fedcenter.gov/programs/eo13423/

Chapter 2,

Justification and

Approval for

Other Than Full

and Open

Competition

External

E.O. 13693,

Planning for

Federal

Sustainability in the

Next Decade

https://energy.gov/lm/downloads/executive-order-13693-planning-federal-

sustainability-next-decade

Chapter 2

External

E.O. 13514, Federal

Leadership in

Environmental,

Energy, and

Economic

Performance

https://www.fedcenter.gov/programs/eo13514/

Chapter 2,

Justification and

Approval for

Other Than Full

and Open

Competition

External

Public Law (P.L.)

109-58, Energy

Policy Act of 2005

https://www.gpo.gov/fdsys/pkg/PLAW-109publ58/pdf/PLAW-109publ58.pdf

Chapter 2

External

10 Code of Federal

Regulations (CFR)

436, Federal Energy

Management and

Planning Programs

(10 CFR 436.18-19)

https://www.gpo.gov/fdsys/search/pagedetails.action?collectionCode=CFR&b

rowsePath=Title+10%2FChapter+II%2FSubchapter+D%2FPart+436%2FSubpart

+A%2FSection+436.18&granuleId=CFR-2002-title10-vol3-sec436-

18&packageId=CFR-2002-title10-vol3&collapse=true&fromBrowse=true

Chapter 2

External

Energy

Independence and

Security Act (EISA)

of 2007

https://www.gpo.gov/fdsys/pkg/PLAW-110publ140/pdf/PLAW-

110publ140.pdf

Air Force Civil Engineer Center

UESC Playbook

28 | P a g e

Section

Type

Name of Item

Linked

Link

Chapter 2,

Justification and

Approval for

Other Than Full

and Open

Competition

External

10 U.S.C. 2866,

Water

Conservation at

Military

Installations

https://www.law.cornell.edu/uscode/text/10/2866

Chapter 2

External

Air Force Policy

Directive (AFPD)

32-10, Installations

and Facilities

http://static.e-publishing.af.mil/production/1/af_a4_7/publication/afpd32-

10/afpd32-10.pdf

Chapter 2

Bookmark

2.3.5 Annual

Reconciliation

Bookmarked to Section 2.3.5 Annual Reconciliation

Chapter 2, 4, 5

Internal

GSA Utility

Contractors list

https://cs2.eis.af.mil/sites/10041/CEPlaybooks/UESC/References/GSA%20Utili

ty%20Contractors%20List.doc

Chapter 2

Bookmark

Risk/Responsibility

Checklist

Bookmarked to the Risk/Responsibility Checklist

Chapter 2

External

42 U.S.C. 8287,

Section

801(a)(2)(A)

https://www.gpo.gov/fdsys/pkg/USCODE-2010-title42/html/USCODE-2010-

title42-chap91-subchapVII.htm

Chapter 2

External

42 U.S.C. 8287;

Section

801(a)(2)(B)

https://www.gpo.gov/fdsys/pkg/USCODE-2010-title42/html/USCODE-2010-

title42-chap91-subchapVII.htm

Chapter 2

External

10 CFR 436, Federal

Energy

Management and

Planning Programs

https://www.gpo.gov/fdsys/granule/CFR-1999-title10-vol3/CFR-1999-title10-

vol3-part436

Chapter 2

External

10 CFR 436.14

https://www.gpo.gov/fdsys/granule/CFR-2011-title10-vol3/CFR-2011-title10-

vol3-sec436-14

Chapter 2

External

Life Cycle Costing

Manual for the

Federal Energy

Management

Program (National

Institute of

Standards and

Technology [NIST]

85-3273)

https://energy.gov/eere/femp/building-life-cycle-cost-programs

Chapter 2

Bookmark

6.5 Maintenance

Related to the TO

Bookmarked to Section 6.5 Maintenance Related to the TO

Chapter 2

External

Title 10 USC §

2913(d)(3)

http://uscode.house.gov/view.xhtml?req=granuleid:USC-prelim-title10-

section2913&num=0&edition=prelim

Chapter 2

External

Purpose Act (31

U.S.C. 1301)

https://www.gpo.gov/fdsys/granule/USCODE-2010-title31/USCODE-2010-

title31-subtitleII-chap13-subchapI-sec1301

Chapter 3, 5

Internal

Considerations for

the BEM

https://cs2.eis.af.mil/sites/10041/CEPlaybooks/UESC/References/UESC%20Co

nsiderations%20for%20the%20%20BEM.docx

Chapter 4, 5

External

FAR 6.302.5

http://www.farmaster.com/farmaster/data/idx/FAR84/0603020005.htm

Chapter 4, 5

Internal

Justification and

Approval for Other

Than Full and Open

Competition

https://cs2.eis.af.mil/sites/10041/CEPlaybooks/UESC/References/JandA%20Fo

rm.docx

Air Force Civil Engineer Center

UESC Playbook

29 | P a g e

Section

Type

Name of Item

Linked

Link

Chapter 4,

Justification and

Approval for

Other Than Full

and Open

Competition

External

FAR 16.703

https://www.acquisition.gov/far/html/Subpart%2016_7.html

Chapter 4

External

DFARS 216.703

http://www.acq.osd.mil/dpap/dars/dfars/html/current/216_7.htm

Chapter 4

External

Procedures,

Guidance and

Information (PGI)

217.703(d)

http://www.acq.osd.mil/dpap/dars/dfars/html/current/216_7.htm

Chapter 4, 5

Internal

EMSA

https://cs2.eis.af.mil/sites/10041/CEPlaybooks/UESC/References/MODEL%20

AGREEMENT.docx

Chapter 4

Bookmark

UESC Planning

Checklist

Bookmarked to the UESC Planning Checklist

Chapter 5

Internal

Sample SOW

https://cs2.eis.af.mil/sites/10041/CEPlaybooks/UESC/References/Sample_SO

W.docx

Chapter 5

External

10 USC 2304(c)(5)

http://uscode.house.gov/view.xhtml?req=10+USC+2304%28c%29%285%29&f

=treesort&fq=true&num=22&hl=true&edition=prelim&granuleId=USC-prelim-

title10-section2304c

Chapter 5

External

Competition in

Contracting Act

(CICA)

http://www.cohenseglias.com/federal-contracting-database/competition-in-

the-contracting-act

Chapter 5

Internal

Task Order Sample

https://cs2.eis.af.mil/sites/10041/CEPlaybooks/UESC/References/UESC%20Ta

sk%20Order%20Sample.docx

Chapter 6

Internal

AFCEC Guide to

M&V Activities

https://cs2.eis.af.mil/sites/10041/CEPlaybooks/UESC/References/AFCEC%20G

uide%20to%20MandV%20Activities.docx

Chapter 6

Bookmark

2.3.4 Maintenance

Responsibilities

Bookmarked to Section 2.3.4 Maintenance Responsibilities

AFCEC Guide to

Annual M&V

Activities

External

Guide to

Government

Witnessing and

Review of Post-

Installation and

Annual M&V

Activities

https://www.energy.gov/eere/femp/downloads/guide-government-

witnessing-and-review-measurement-and-verification-activities

AFCEC Guide to

Annual M&V

Activities

External

Reviewing Post-

Installation and

Annual Reports for

Federal ESPC

Projects

https://energy.gov/eere/femp/downloads/reviewing-post-installation-and-

annual-reports-federal-espc-projects

AFCEC Guide to

Annual M&V

Activities

External

FEMP webpage

https://energy.gov/eere/femp/federal-energy-management-program

UESC

Considerations

for the BEM

Internal

AFCEC Guide to

M&V Activities

https://cs2.eis.af.mil/sites/10041/CEPlaybooks/UESC/References/AFCEC%20G

uide%20to%20MandV%20Activities.docx

Justification and

Approval for

Other Than Full

and Open

Competition

External

10 U.S.C. 2913

(D)(3)

https://www.gpo.gov/fdsys/pkg/USCODE-2010-title10/pdf/USCODE-2010-

title10-subtitleA-partIV-chap173-subchapI-sec2913.pdf

Air Force Civil Engineer Center

UESC Playbook

30 | P a g e

Section

Type

Name of Item

Linked

Link

EMSA/Model

Agreement

External

48 CFR 9.404

https://www.law.cornell.edu/cfr/text/48/9.404

EMSA/Model

Agreement

External

FAR, Part 36,

Subpart 36.511

https://www.acquisition.gov/sites/default/files/current/far/html/Subpart%20

36_5.html

EMSA/Model

Agreement

External

FAR, Part 52,

Subpart 52.301

https://www.gpo.gov/fdsys/granule/CFR-2011-title48-vol2/CFR-2011-title48-

vol2-sec52-301

EMSA/Model

Agreement

External

Energy Prices and

Discount Factors

for Life-Cycle-Cost

Analysis

http://nvlpubs.nist.gov/nistpubs/ir/2017/NIST.IR.85-3273-32.pdf

EMSA/Model

Agreement

External

FAR 52.203-3,

Gratuities

https://www.acquisition.gov/sites/default/files/current/far/html/52_200_206

.html

EMSA/Model

Agreement

External

FAR 52.203-5,

Covenant Against

Contingent Fees

https://www.acquisition.gov/sites/default/files/current/far/html/52_200_206

.html

EMSA/Model

Agreement

External

FAR 52.203-7, Anti-

Kickback

Procedures

https://www.acquisition.gov/sites/default/files/current/far/html/52_200_206

.html

EMSA/Model

Agreement

External

FAR 52.222-3,

Convict Labor

https://www.acquisition.gov/sites/default/files/current/far/html/52_222.html

EMSA/Model

Agreement

External

FAR 52.222-25,

Affirmative Action

Compliance

https://www.acquisition.gov/sites/default/files/current/far/html/52_222.html

EMSA/Model

Agreement

External

FAR 52.222-26,

Equal Opportunity

https://www.acquisition.gov/sites/default/files/current/far/html/52_222.html

EMSA/Model

Agreement

External

FAR 52.223-6, Drug

Free Workplace

https://www.law.cornell.edu/cfr/text/48/52.223-6

EMSA/Model

Agreement

External

FAR 52.233-1,

Disputes

https://www.acquisition.gov/sites/default/files/current/far/html/52_233_240

.html

EMSA/Model

Agreement

External

FAR Part 52,

Subpart 52.246-20

https://www.govregs.com/regulations/title48_chapter1_part52_subpart52.2_

section52.246-20

EMSA/Model

Agreement

External

FAR Part 32,

Subpart 32.903

http://federal.elaws.us/cfr/title48.part32.section32.903

EMSA/Model

Agreement

External

FAR Part 32,

Subpart 32.907

https://www.acquisition.gov/sites/default/files/current/far/html/Subpart%20

32_9.html#wp1033041

EMSA/Model

Agreement

External

FAR Part 33,

Subpart 33.2

https://www.acquisition.gov/sites/default/files/current/far/html/Subpart%20

33_2.html

EMSA/Model

Agreement

External

FAR Part 36,

Subpart 36.502

https://www.acquisition.gov/sites/default/files/current/far/html/Subpart%20

36_5.html#wp1076711

EMSA/Model

Agreement

External

FAR Part 42,

Subpart 42.13

https://www.law.cornell.edu/cfr/text/48/part-42/subpart-42.13

EMSA/Model

Agreement

External

10 USC Section

2912

https://www.law.cornell.edu/uscode/text/10/2912

EMSA/Model

Agreement, UESC

Task Order (TO)

Sample

External

FAR Part 17

https://www.acquisition.gov/sites/default/files/current/far/html/FARTOCP17.

html

EMSA/Model

Agreement, UESC

Task Order (TO)

Sample

External

FAR Part 52,

Subpart 52.249-2

https://www.acquisition.gov/sites/default/files/current/far/html/52_248_253

.html

Air Force Civil Engineer Center

UESC Playbook

31 | P a g e

Section

Type

Name of Item

Linked

Link

EMSA/Model

Agreement, UESC

Task Order (TO)

Sample

External

FAR Part 52,

Subpart 52.232.23

https://www.acquisition.gov/sites/default/files/current/far/html/52_2

32.html#wp1152984

EMSA/Model

Agreement, UESC

Task Order (TO)

Sample

External

FAR Part 32,

Subpart 32.8

https://www.law.cornell.edu/cfr/text/48/part-32/subpart-32.8

EMSA/Model

Agreement

External

FAR Part 42,

Subpart 42.12

https://www.acquisition.gov/sites/default/files/current/far/html/Subpart%20

42_12.html

EMSA/Model

Agreement

External

FAR Part 42,

Subpart 42.1204

https://www.acquisition.gov/sites/default/files/current/far/html/Subpart%20

42_12.html

EMSA/Model

Agreement

External

42 U.S.C. §9601

https://www.law.cornell.edu/uscode/text/42/9601

EMSA/Model

Agreement

External

49 CFR Part 172

https://www.gpo.gov/fdsys/pkg/CFR-1998-title49-vol2/xml/CFR-1998-title49-

vol2-part172.xml

EMSA/Model

Agreement

External

FAR Part 52,

Subparts 52.236-2

https://www.acquisition.gov/far/html/52_233_240.html#wp1113365

EMSA/Model

Agreement

External

52.236-3

https://www.acquisition.gov/sites/default/files/current/far/html/52_2

33_240.html#wp1113375

UESC Task Order

(TO) Sample

External

10 CFR 851

https://www.gpo.gov/fdsys/granule/CFR-2012-title10-vol4/CFR-2012-title10-

vol4-part851

UESC Task Order

(TO) Sample

External

FAR 52.246-21

http://www.farmaster.com/farmaster/data/idx/FAR84/5202460021I.htm

UESC Task Order

(TO) Sample

External

FAR 52.236-13

https://www.gpo.gov/fdsys/pkg/CFR-2010-title48-vol2/pdf/CFR-2010-title48-

vol2-sec52-236-13.pdf

UESC Task Order

(TO) Sample

External

FAR 52.228-5

http://farmaster.com/farmaster/data/idx/FAR84/5202280005.htm

Air Force Civil Engineer Center

UESC Playbook

32 | P a g e

Appendix C - Job Aids

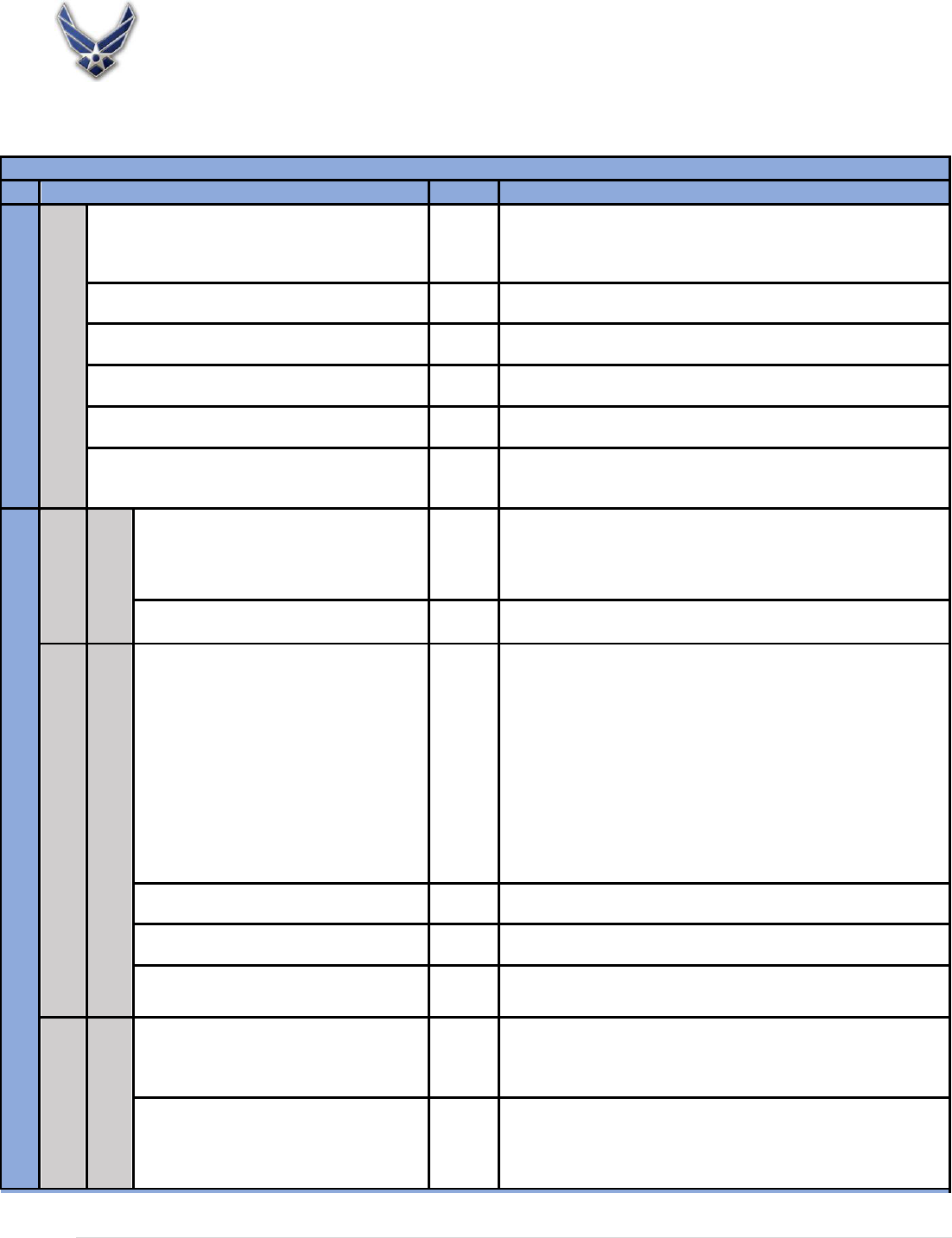

UESC Planning Checklist

UESC Planning and Document Development Checklist

Process Step/Resource Name

Type

Objective

Step 1 Acquisition Planning

2 - 4 weeks

Agency (e.g., installation) develops initial SOW and

submits all proposed UESC projects to AFCEC/CND

as PMO for initial vetting prior to any UESC

engagement with the utility provider.

Sample

Ensure the Agency obtains AFCEC approval to start an UESC prior

to any UESC engagement with the utility provider.

Acquisition Strategy/Planning

Limited Acquisition Plan

Template

Establishes the agency’s strategy for the acquisition of the project.

Survey interest of eligible Utilities

Letter of Interest

Template

Used to determine which servicing utilities are interested and

capable.

Provide fair consideration to interested utilities

Utility Selection Evaluation Factors

Sample

Detailed utility selection sample for a $60M UESC Project.

Draft Initial J&A

J&A

Sample

A sample justification to use a “limited source” contract.

Agency selects utility and notifies all utilities of

selection

Utility Selection Letter

Template

Notifies all serving utilities of the selection.

Step 2 Project Development

Preliminary

Assessment

2 - 4 Weeks

EMSA for PA

EMSA

Letter of Request for PA

PA SOW

Sample

Template