BY ORDER OF THE

SECRETARY OF THE AIR FORCE

DEPARTMENT OF THE AIR FORCE

INSTRUCTION 63-101/20-101

16 FEBRUARY 2024

Acquisition/Logistics

INTEGRATED LIFE CYCLE

MANAGEMENT

COMPLIANCE WITH THIS PUBLICATION IS MANDATORY

ACCESSIBILITY: Publications and forms are available on the e-Publishing website at

www.e-Publishing.af.mil for downloading or ordering.

RELEASABILITY: There are no releasability restrictions on this publication.

OPR: SAF/AQXS Certified by: SAF/AQX

(Mr. Mark Murphy)

Supersedes: AFI 63-101/20-101, 30 June 2020 Pages: 196

This publication implements Air Force Policy Directive (AFPD) 63-1/20-1, Integrated Life Cycle

Management. This instruction establishes the Integrated Life Cycle Management guidelines and

procedures for Department of Air Force (DAF) personnel who develop, review, approve or manage

systems, subsystems, end-items, services, and activities (for the purpose of this publication

referred to as programs throughout this document) procured under Department of Defense (DoD)

5000 series instructions comprising the Defense Acquisition System. Additionally, this DAF

Instruction (DAFI) supports guidance provided in the Office of Management and Budget Circular

A-11, Preparation, Submission, and Execution of the Budget; Department of Defense Instruction

(DoDI) 2000.25, DoD Procedures for Reviewing and Monitoring Transactions Filed with the

Committee on Foreign Investment in the United States (CFIUS); DoDI 2040.03, End Use

Certificates (EUC); DoDI 3020.41, Operational Contract Support (OCS); DoDI 3200.19, Non-

Lethal Weapons (NLW) Human Effects Characterization; DoDI 3200.20, Scientific and

Engineering Integrity; DoDI 4140.73, Asset Physical Accountability Policy; DoDI 4151.19,

Serialized Item Management for Life Cycle Management of Materiel; DoDI 4151.20, Depot

Maintenance Core Capabilities Determination Process; DoDI 4151.21, Public-Private

Partnerships for Product Support; DoDI 4151.22, Condition Based Maintenance Plus for Materiel

Maintenance; DoDI 4245.14, DoD Value Engineering (VE) Program; DoDI 4245.15, Diminishing

Manufacturing Sources and Material Shortages Management; DoDI 5000.02, Operation of the

Adaptive Acquisition Framework; DoDI 5000.60, Defense Industrial Base Assessments; DoDI

5000.67, Prevention and Mitigation of Corrosion on DOD Military Equipment and Infrastructure;

DoDI 5000.69, DoD Joint Services Weapon and Laser System Safety Review Process; DoDI

5000.82, Acquisition of Information Technology (IT); DoDI 5000.86, Acquisition Intelligence;

2 DAFI63-101/20-101 16 FEBRUARY 2024

DoDI 5000.87, Operation of the Software Acquisition Pathway; DoDI 5000.88, Engineering of

Defense Systems; DoDI 5000.89, Test and Evaluation; DoDI 5000.91, Product Support

Management for the Adaptive Acquisition Framework; DoDI 5000.92, Innovation and Technology

to Sustain Materiel Readiness; DoDI 8320.03, Unique Identification (UID) Standards for

Supporting DoD Information Enterprise; DoDI 8320.04, Item Unique Identification (IUID)

Standards for Tangible Personal Property; and DoDI 8320.06, Organization Unique Identification

(OUID) Standards for Unique Identification of External Department of Defense Business

Partners. This publication is applicable to the entire DAF, including all uniformed members of

the Regular Air Force, United States Space Force, Air Force Reserve and Air National Guard,

except where otherwise noted, all DAF civilian employees, and those with a contractual obligation

to abide by the terms of this publication. Soley when used within this instruction, the term

“MAJCOM” includes and should be interpreted to include FLDCOMs, direct reporting units

(DRU), and field operating agencies (FOA). The term “Wing” should be interpreted to include

“Delta,” as appropriate. Tier waiver authority is addressed in Chapter 1, paragraph 1.4. This

DAFI may be supplemented at any level, but all supplements must be routed to the Deputy

Assistant Secretary (Acquisition Integration) (SAF/AQX) for review and approval prior to

publication. Compliance with the attachments in this publication is mandatory. Refer

recommended changes and questions about this publication to SAF/AQXS using DAF Form 847,

Recommendation for Change of Publication; route DAF Forms 847 from the field through the

appropriate functional chain of command. Ensure all records generated as a result of processes

prescribed in this publication adhere to Air Force Instruction 33-322, Records Management and

Information Governance Program, and are disposed in accordance with the Air Force Records

Disposition Schedule, which is located in the Air Force Records Information Management System.

The use of the name or mark of any specific manufacturer, commercial product, commodity, or

service in this publication does not imply endorsement by the DAF.

SUMMARY OF CHANGES

This document was revised to remove acquisition pathway specific guidance contained in new

DAF supplements. Additional changes include the implementation of new DoD issuances,

addressing organizational changes including those resulting in the creation of the United States

Space Force (USSF), changes to roles and responsibilities, and changes to reflect two DAF Service

Acquisition Executives.

Chapter 1—INTEGRATED LIFE CYCLE MANAGEMENT 8

1.1. Overview. ................................................................................................................. 8

1.2. Applicability. ........................................................................................................... 8

Figure 1.1. Adaptive Acquisition Framework. ........................................................................... 10

1.3. Acquisition Execution Chain of Authority. ............................................................. 13

Table 1.1. MDA Delegation. ..................................................................................................... 14

1.4. Waiver Authority (Tiering) and Tailoring. .............................................................. 16

1.5. PEO Portfolio Assignment or Transfer. ................................................................... 17

DAFI63-101/20-101 16 FEBRUARY 2024 3

Chapter 2—ROLES AND RESPONSIBILITIES 20

2.1. Purpose. ................................................................................................................... 20

2.2. Service Acquisition Executive. ................................................................................ 20

2.3. Senior Procurement Executive (SPE). ..................................................................... 20

2.4. Milestone Decision Authority. ................................................................................. 20

2.5. Program Executive Officer. ..................................................................................... 21

2.6. Program Manager (PM). .......................................................................................... 22

2.7. Product Support Manager. ....................................................................................... 23

2.8. Chief Engineer. ........................................................................................................ 23

2.9. Chief Developmental Tester (Test Manager)........................................................... 24

2.10. Acquisition Intelligence Analyst. ............................................................................. 24

2.11. Implementing Commanders. .................................................................................... 25

2.12. Authorizing Official (AO). ...................................................................................... 26

2.13. Operational Command, Direct Reporting Unit (DRU), and Field Operating

Agency (FOA) Commanders. .................................................................................. 26

2.14. Service Intelligence Center Commander. ................................................................ 27

2.15. Acquisition Security Professional. ........................................................................... 27

2.16. Technology Executive Officer (TEO). .................................................................... 27

Chapter 3—DEPARTMENT OF THE AIR FORCE OPERATION OF THE DEFENSE

ACQUISITION SYSTEM 28

3.1. Capability-Based Requirements Development. ....................................................... 28

3.2. Milestone Decision Authority Determinations and Certifications. .......................... 28

3.3. Acquisition Review Boards and Acquisition Strategy Panels. ................................ 28

3.4. Configuration Steering Board. ................................................................................. 29

3.5. Science and Technology. ......................................................................................... 30

3.6. Program Work Breakdown Structure. ...................................................................... 31

3.7. Integrated Master Plans (IMP) and Integrated Master Schedules (IMS). ................ 31

3.8. Performance Measurement Baseline Analysis. ........................................................ 31

3.9. Earned Value Management (EVM). ........................................................................ 31

3.10. Affordability Analysis. ............................................................................................ 32

3.11. Post Implementation Review. .................................................................................. 33

3.12. Independent Reviews. .............................................................................................. 33

3.13. Weapon and Cyber Legality Reviews. ..................................................................... 33

4 DAFI63-101/20-101 16 FEBRUARY 2024

3.14. Program Terminations. ............................................................................................ 33

3.15. Exportability Reviews and Waivers. ........................................................................ 33

3.16. National Security System Designation Determination. ........................................... 34

Chapter 4—PROGRAM ACTIVITIES 35

4.1. Program Integration. ................................................................................................ 35

4.2. Program Documentation. ......................................................................................... 35

4.3. Acquisition Strategy. ............................................................................................... 36

4.4. Program Baseline. .................................................................................................... 36

4.5. Risk-Based Program Management and Decision Making. ...................................... 37

4.6. Small Business Integrated Life Cycle Management Activities................................ 41

4.7. Intellectual Property (IP).......................................................................................... 41

4.8. Test Planning. .......................................................................................................... 46

4.9. Modeling and Simulation. ........................................................................................ 47

4.10. Government Cost Estimates. .................................................................................... 48

4.11. Program Funding. .................................................................................................... 49

4.12. New Start Notification. ............................................................................................ 49

4.13. Use of Specifications and Standards. ....................................................................... 50

4.14. Intelligence Supportability Analysis. ....................................................................... 50

4.15. Arms Control Compliance. ...................................................................................... 52

4.16. Procurement Fraud. .................................................................................................. 53

4.17. Missile Defense Agency Related Acquisition. ........................................................ 53

4.18. Nuclear Weapon Related Policy. ............................................................................. 53

4.19. Management of DAF Training Systems. ................................................................. 54

4.20. End Use Certificate. ................................................................................................. 54

4.21. Auditability. ............................................................................................................. 55

4.22. General Equipment Valuation. ................................................................................. 56

4.23. Serialized Item Management. .................................................................................. 57

4.24. Item Unique Identification Planning. ....................................................................... 58

4.25. Government Furnished Property. ............................................................................. 59

4.26. Industrial Base Constraints and Supply Chain Risk Management (SCRM)

Integration. ............................................................................................................... 59

4.27. Other Acquisition Planning Factors. ........................................................................ 62

Table 4.1. Other Acquisition Planning Factors. ........................................................................ 62

DAFI63-101/20-101 16 FEBRUARY 2024 5

Chapter 5—SYSTEMS ENGINEERING 68

5.1. Systems Engineering (SE) Overview. ...................................................................... 68

5.2. Systems Engineering Processes. .............................................................................. 71

5.3. System Engineering Activities in the Life Cycle. .................................................... 76

5.4. Systems Engineering Design Considerations. ......................................................... 77

Figure 5.1. Use Cases for 95 Percent Accommodation. ............................................................. 85

Chapter 6—PROGRAM PROTECTION 93

6.1. Program Protection Overview.................................................................................. 93

6.2. Program Protection Planning. .................................................................................. 93

6.3. Communications Security (COMSEC). ................................................................... 94

6.4. Anti-Tamper. ............................................................................................................ 94

6.5. Operations Security (OPSEC). ................................................................................. 95

6.6. Counterintelligence. ................................................................................................. 95

6.7. Foreign Intelligence. ................................................................................................ 95

6.8. System Security Engineering. .................................................................................. 95

6.9. Trusted Systems and Networks. ............................................................................... 95

6.10. Acquisition Security. ............................................................................................... 96

6.11. Cybersecurity. .......................................................................................................... 96

6.12. Nuclear Systems Security. ....................................................................................... 96

6.13. Physical Security. ..................................................................................................... 96

6.14. Supply Chain Risk Management. ............................................................................ 97

6.15. Cyber-Supply Chain Risk Management. ................................................................. 97

Chapter 7—PRODUCT SUPPORT 98

7.1. Product Support and Sustainment Planning Overview. ........................................... 98

7.2. Product Support Business Model. ............................................................................ 98

7.3. Weapon System Sustainment. .................................................................................. 98

7.4. Centralized Asset Management (CAM). .................................................................. 99

7.5. Product Support Strategy. ........................................................................................ 99

7.6. Product Support Business Case Analysis. ............................................................... 99

7.7. Life Cycle Sustainment Plan. ................................................................................... 100

7.8. Materiel Fielding. ..................................................................................................... 103

7.9. Product Support and Logistics Assessments. ........................................................... 104

7.10. Sustainment Metrics. ............................................................................................... 105

6 DAFI63-101/20-101 16 FEBRUARY 2024

7.11. Depot Maintenance and Sustainment Cost Reporting. ............................................ 106

7.12. Depot Purchased Equipment Maintenance. ............................................................. 106

7.13. Depot Source of Repair. ........................................................................................... 107

7.14. Contractor Logistics Support. .................................................................................. 107

7.15. Public-Private Partnerships. ..................................................................................... 109

7.16. Technical Orders. ..................................................................................................... 111

7.17. Support Equipment/Automatic Test Systems (SE/ATS). ........................................ 114

7.18. Provisioning. ............................................................................................................ 114

7.19. Divestiture Planning. ............................................................................................... 115

7.20. Demilitarization, Removal from Service, Disposal, Reclamation, and Migration. . 115

7.21. Propulsion Management. ......................................................................................... 116

Chapter 8—GUIDANCE APPLICABLE TO PROGRAMS CONTAINING

INFORMATION TECHNOLOGY 118

8.1. Networks and Information Integration Requirements Overview. ............................ 118

8.2. Planning Requirements. ........................................................................................... 118

Table 8.1. Programs Containing Information Technology Requirements. ............................... 118

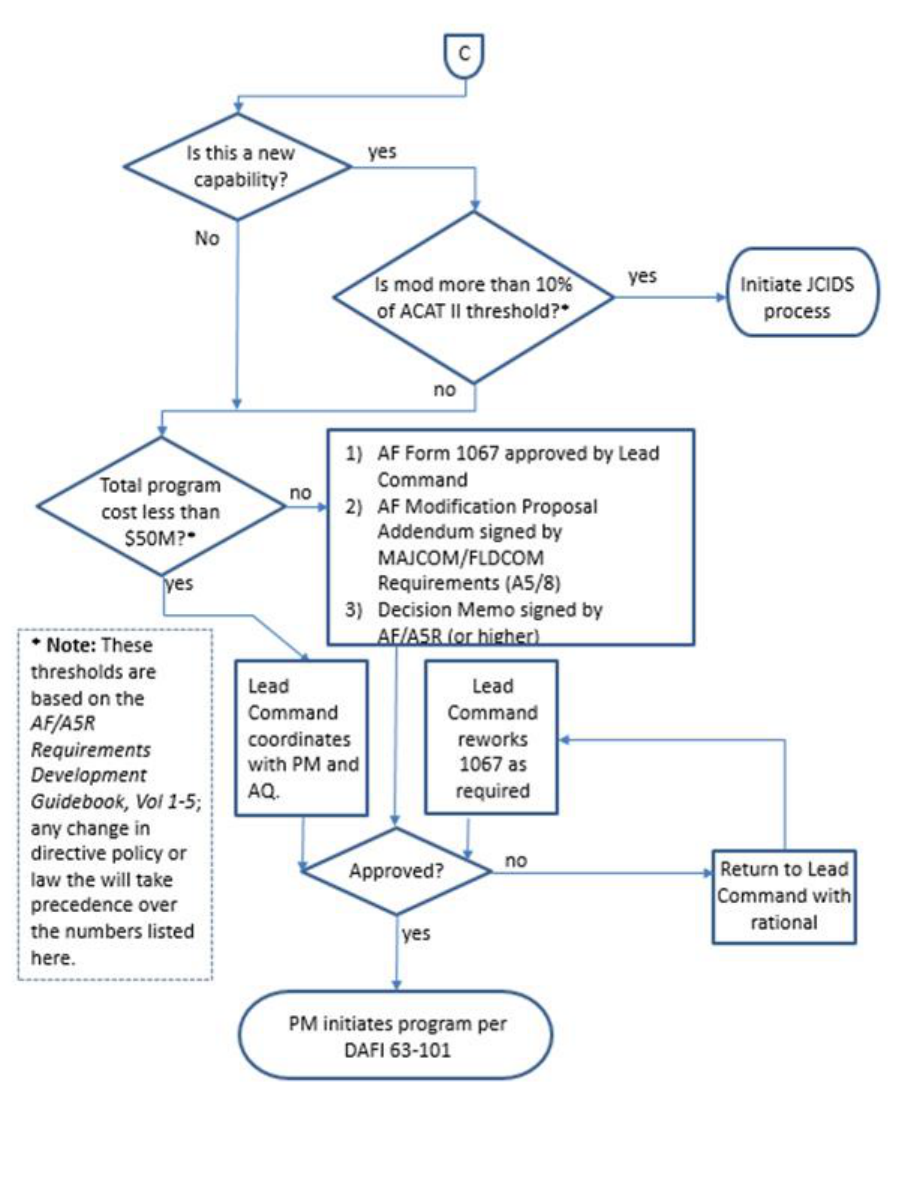

Chapter 9—MODIFICATION MANAGEMENT 124

9.1. Modification Management Overview. ..................................................................... 124

9.2. AF Form 1067 Applicability. ................................................................................... 124

9.3. Modification Types. ................................................................................................. 125

9.4. Modifications to Assets Planned for Retirement (or Sunset Provisions). ................ 130

9.5. Additional Modification Requirements. .................................................................. 131

9.6. Modification Fielding and Installation. .................................................................... 134

9.7. Modification Close-out. ........................................................................................... 134

9.8. Modification Management Reporting. ..................................................................... 135

Chapter 10—ACQUISITION WORKFORCE MANAGEMENT AND PROFESSIONAL

DEVELOPMENT 136

10.1. Overview. ................................................................................................................. 136

10.2. Acquisition Workforce. ........................................................................................... 136

10.3. Responsibilities and Authorities. ............................................................................. 136

10.4. AF Acquisition Professional Development Program. .............................................. 137

Chapter 11—REPORTING 143

11.1. Reporting Requirements. ......................................................................................... 143

DAFI63-101/20-101 16 FEBRUARY 2024 7

11.2. Investment Fund Reporting. ..................................................................................... 143

11.3. Investment Master List, Acquisition Master List, and AML-Exempt activities. ..... 144

Figure 11.1. IML, AML, AML-Exempt Relationship. ................................................................ 145

11.4. Management Acquisition Reports. ........................................................................... 146

Table 11.1. Management Acquisition Reporting Frequency. ..................................................... 147

11.5. Modification Management Reporting. ..................................................................... 148

11.6. Logistics Health Assessment Reporting. ................................................................. 149

11.7. Test and Evaluation Reporting. ................................................................................ 149

Chapter 12—ACQUISITION INDUSTRIAL PREPAREDNESS 150

12.1. Acquisition Industrial Preparedness Overview. ....................................................... 150

12.2. Industrial Facilities. ................................................................................................. 150

12.3. Additional Responsibilities and Authorities. ........................................................... 151

12.4. Permissible Funding. ............................................................................................... 152

12.5. Leases. ..................................................................................................................... 153

Attachment 1—GLOSSARY OF REFERENCES AND SUPPORTING INFORMATION 154

Attachment 2—MODIFICATION PROPOSAL PROCESS AND AF FORM 1067

DESCRIPTIONS 174

Attachment 3—LIFE CYCLE RISK MANAGEMENT RISK MATRIX DEFINITIONS 189

Attachment 4—DETERMINATION FOR NATIONAL SECURITY SYSTEMS (NSS) 194

8 DAFI63-101/20-101 16 FEBRUARY 2024

Chapter 1

INTEGRATED LIFE CYCLE MANAGEMENT

1.1. Overview. DAFI 63-101/20-101, Integrated Life Cycle Management, contains directive

overarching processes and procedures required to deliver and sustain warfighting capabilities.

Integrated Life Cycle Management governs all aspects of infrastructure, resource management,

and business systems necessary for the successful acquisition of systems, subsystems, end items,

and services to satisfy validated warfighter or user requirements. This publication was written to

be used with pathway-specific directive guidance provided in DoD and DAF issuances, and non-

directive best practices and procedures provided in DAF Pamphlet (DAFPAM) 63-128, Integrated

Life Cycle Management, and AFPAM 63-129, Air System Development and Sustainment

Engineering Processes and Procedures.

1.2. Applicability. This instruction applies to the management of space and non-space

acquisition programs to include weapons, weapons systems, national security systems, business

systems, and all investment-funded activities (for the purpose of this publication referred to as

programs throughout this document), in any phase of the life cycle. This instruction applies to

acquisition programs using pathways in the adaptive acquisition framework (AAF) as defined in

DoDI 5000.02 and shown in Figure 1.1 below. DAF acquisition programs begin by utilizing

investment funding (i.e., research, development, test, and evaluation (RDT&E) or procurement) to

satisfy a validated need.

1.2.1. Modifications. Modifications to systems are addressed in Chapter 9. Permanent

modifications to an operational capability may result in a new acquisition program and

appropriate pathway-specific guidance would also apply (e.g., DoDI 5000.85_DAFI 63-151,

Major Capability Acquisition). Modifications using investment funding are included on the

Acquisition Master List (AML) regardless of pathway.

1.2.2. Maintenance. Maintenance activities for existing programs that are not considered a

permanent modification and do not utilize investment funding are not required to be managed

as a new acquisition program. Maintenance activities are managed in accordance with

maintenance and program specific processes. This instruction does not apply to the following

modification and maintenance activities:

1.2.2.1. Replacement of interchangeable items which do not involve the alteration of an

existing asset. Military Handbook (MIL-HDBK)-61B, Configuration Management

Guidance, considers an interchangeable product one which possesses such functional and

physical attributes as to be equivalent in performance to another product of similar or

identical purposes and is capable of being exchanged with the other product without

alteration of the products themselves or of adjoining products.

1.2.2.2. Operations and Maintenance (O&M) funded actions that keep a previously

established level of performance through routine, recurring work correction of product

quality deficiencies, restoration of the functional baseline or performance specification,

and do not extend service life of the equipment or alter form, fit, function, or interface.

Note: Individual engineering changes completed as part of an existing acquisition program

involving developmental items or production articles that have not been formally accepted

DAFI63-101/20-101 16 FEBRUARY 2024 9

by the government via a Department of Defense (DD) Form 250, Material Inspection and

Receiving Report are not considered operations and maintenance funded actions.

1.2.2.2.1. This includes depot-level maintenance and repair as defined in Title 10

United States Code (USC) Section 2460, Definition of Depot-Level Maintenance and

Repair, and maintenance actions such as the materiel repair, overhaul, rebuilding of

parts, assemblies, subassemblies, and the testing and reclamation of equipment to

correct a deficient condition in the originally designed functionality.

1.2.2.2.2. Tech refresh to maintain and/or optimize operational readiness of

commercially available office information systems and associated software.

1.2.2.2.3. Assets that are no longer part of an active inventory, such as aircraft in long-

term storage that are not part of a reutilization effort.

1.2.2.2.4. Modifications of facilities or other base-level infrastructure,

telecommunications equipment, or property.

10 DAFI63-101/20-101 16 FEBRUARY 2024

Figure 1.1. Adaptive Acquisition Framework.

1.2.3. Major Capability (Acquisition Category (ACAT)) Programs. Additional detailed

guidance for ACAT programs, also known as Major Capability Acquisition (MCA) programs,

is in DoDI 5000.85_DAFI 63-151, Major Capability Acquisition. DoDI 5000.85_DAFI 63-

151 defines and provides the criteria for ACAT programs. Programs retain their ACAT

designation through sustainment, until demilitarized, disposed of, or terminated. MCA

programs are categorized on the AML and the Investment Master List (IML) depending on

phase and funding type.

1.2.4. Defense Business Systems (DBS). Additional detailed guidance for DBS is in DoDI

5000.75_DAFI 63-144, Business System Requirements Acquisition. DBS programs are subject

to AML categorization and acquisition reporting.

1.2.5. The Middle Tier of Acquisition (Rapid Prototyping and Rapid Fielding). Additional

detailed guidance for Middle Tier of Acquisition programs is in DoDI 5000.80_DAFI 63-146,

Operation of the Middle Tier of Acquisition (MTA). MTA programs are subject to AML

categorization and acquisition reporting.

DAFI63-101/20-101 16 FEBRUARY 2024 11

1.2.6. Software Acquisition. Additional detailed guidance for software acquisition pathway

programs is in DoDI 5000.87_DAFI 63-150, Operation of the Software Acquisition Pathway.

Software programs are subject to AML categorization and acquisition reporting. Note: Not all

software or software-intensive programs must use the Software Acquisition Pathway. Program

managers (PM) may choose the pathway from the AAF given their program’s objectives and

resources.

1.2.7. Urgent Capability Acquisition (UCA). Additional detailed guidance for UCA is in

DoDI 5000.81_DAFI 63-147, Urgent Capability Acquisition. UCA includes rapid acquisition

programs responding to an approved Joint Urgent Operational Need (JUON), Joint Emergent

Operational Need (JEON), or Urgent Operational Need (UON). Urgent capability programs

are subject to AML categorization and acquisition reporting.

1.2.8. Acquisition of Services. Acquisition of services are AML-exempt investment activities

and follow the guidance in DoDI 5000.74, Defense Acquisition of Services and AFI 63-138,

Acquisition of Services.

1.2.9. Sustainment Activities. This publication provides guidance for programs in the

Operations and Support Phase including programs or systems utilizing O&M funding.

Systems in the Operations and Support Phase are not required to retroactively meet information

requirements identified in previous phases of the acquisition life cycle. These systems should

continue to meet the requirements needed for continued operation to include modifications and

maintenance activities. Sustainment activities utilizing investment funding should be

categorized as either an AML or AML-Exempt program and report funding in accordance with

this DAFI (see Chapter 11).

1.2.10. Other Acquisition Master List-Exempt Investment Activities. All investment

activities are required to report investment funding and be categorized as AML-Exempt per

Chapter 11. Investment activities are required to comply with Federal Acquisition Regulation

(FAR) and financial management requirements as defined. AML-Exempt investment

activities, except services, are not considered acquisition pathway programs and are not

required to follow DoDD 5000.01, The Defense Acquisition System, guidance related to the

management of acquisition programs. AML-Exempt investment activities include, but are not

limited to:

1.2.10.1. Civilian Pay (Investment-Funded), Commodity Procurements, Developmental

Infrastructure Sustainment, Development of Enterprise Architectures/Certifications, and

Replenishment Spares Procurements.

1.2.10.2. Studies. Studies using investment funds or in support of a program.

1.2.10.3. Technology Projects. Note: The management procedures of this DAFI do not

apply to science and technology programs, demonstrations, experiments, or projects

managed using AFI 61-101, Management of Science and Technology.

1.2.11. Special Access Program (SAP). The PM collaborates with SAF/AAZ when SAP

information is involved to determine a prudent program protection planning approach prior to

developing a program protection plan (PPP), reference DoDI 5000.83_DAFI 63-113,

Technology and Program Protection to Maintain Technological Advantage for additional

guidance. SAPs are managed in accordance with DoDD 5205.07, Special Access Program

(SAP) Policy, DoDI 5205.11, Management, Administration, and Oversight of DoD Special

12 DAFI63-101/20-101 16 FEBRUARY 2024

Access Programs (SAPs), AFPD 16-7, Special Access Programs and AFI 16-701,

Management, Administration and Oversight of Special Access Programs.

1.2.11.1. Collateral programs with acknowledged SAP elements are required to follow the

guidance in this DAFI unless specifically exempt by this or other publications.

1.2.11.2. For all other SAP programs, the Assistant Secretary of the Air Force for

Acquisition, Directorate of Special Programs (SAF/AQL), in consultation with the

Assistant Secretary for the Air Force for Space Acquisition and Integration, Integration

Directorate (SAF/SQX) if space related, will assess all acquisition policy and instructions

for application to SAPs and establish acquisition policy specific to SAPs in accordance

with AFI 16-701. SAF/AQL, SAF/AQX, and SAF/SQX in coordination with the Director,

Security, Special Programs Oversight and Information Protection (SAF/AAZ), are

responsible for these activities.

1.2.11.3. SAF/AAZ reviews Committee on Foreign Investment in the United States

transactions received from DoD Special Access Program Central Office and is the DAF

responsible party as the Cognizant Security Authority pursuant to DoDI 5205.11.

1.2.12. Security Cooperation and Foreign Military Sales (FMS). Security Cooperation and

FMS programs support United States (U.S.) foreign policy and national security objectives by

enabling the United States to build, sustain, expand, and guide international partnerships that

are critical enablers for its national security objectives.

1.2.12.1. Security Cooperation and FMS acquisition programs are executed in accordance

with the Arms Export Control Act, 22 USC Section 2751; Defense Security Cooperation

Agency 5105.38-M, Security Assistance Management Manual; DoD Financial

Management Regulation 7000.14-R, Department of Defense Financial Management

Regulation; and AFMAN 16-101, Security Cooperation (SC) and Security Assistance (SA)

Management.

1.2.12.2. FMS programs are implemented based on the direction in the DoD 5000

acquisition series, DoD 5200 series, DAF 99-series test publications, DAF 62-series

engineering publications, DAF 63-series acquisition publications, DAF 14-series

intelligence publications, and DAF 16-series operations support publications to afford the

foreign purchaser the same benefits and protections that apply to DoD procurement. The

applicability to each FMS case of tailored requirements or application of unique

requirements from these policies is limited to what is contained in the government-to-

government agreement.

1.2.12.3. FMS program requirements are contained in a government-to-government

agreement. This agreement is implemented for execution through the appropriate

accountability reporting chain of the assigned DoD component authority.

1.2.12.3.1. The government-to-government agreement established by a bilaterally

signed Letter of Offer and Acceptance specifies any tailored implementation of

acquisition direction for the FMS program.

1.2.12.3.2. Collaboration with the user occurs as early as possible in the program’s life

cycle on the feasibility of exportable and interoperable configurations and open system

architectures in the system design based on an analysis of current and future

DAFI63-101/20-101 16 FEBRUARY 2024 13

international market. This can enable more timely and efficient future FMS cases;

however, changes adding requirements or costs must be approved by the user.

1.2.12.3.3. FMS programs are not included on the IML; however, the PM for FMS

programs uses the Project Management Resource Tool (PMRT) Management

Acquisition Report (MAR) to capture specified programmatic, contracting, and

financial data. Reference AFMAN 16-101 for guidance.

1.3. Acquisition Execution Chain of Authority. The DAF acquisition chain of authority reflects

the management structure from the Service Acquisition Executive (SAE) through the Program

Executive Officer (PEO) to the accountable PM. Note: The SAE is referred to as the Component

Acquisition Executive (CAE) in DoD issuances. The acquisition chain of authority should be

streamlined and characterized by short, clearly defined lines of responsibility, authority, and

accountability and minimize levels of review between the PM and the decision authority. Only

those in the acquisition execution chain of authority exercise decision-making authority on

programmatic matters. The PM documents the acquisition execution chain of authority in the

Acquisition Strategy. The acquisition chain of authority includes the following:

1.3.1. Milestone Decision Authority (MDA) or Decision Authority (DA). The MDA, also

referred to as DA for pathways without milestones, has the authority to approve entry of a

program into the next phase of the life cycle process, certify milestone or other decision point

criteria, and is accountable for cost, schedule, and performance reporting to higher authority,

including Congress. The authority of the MDA and delegation is defined in Table 1.1. For

acquisition of services, decision authority delegations are in AFI 63-138. References to MDA

in this publication apply to the person with program decision authority and overall

responsibility for a program regardless of pathway.

1.3.1.1. The Defense Acquisition Executive (DAE) is the MDA for ACAT ID programs

in accordance with the guidelines specified in DoDI 5000.85.

1.3.1.2. The SAE is the MDA for ACAT IB, ACAT IC, Business Category (BCAT) I, and

special interest programs. The SAE is the MDA for Middle Tier and software pathway

programs meeting the criteria of a Major Defense Acquisition Program (MDAP) unless

delegated. Reference DoDI 5000.85_DAFI 63-151 for MDAP criteria.

1.3.1.2.1. MDA responsibilities for ACAT II, ACAT III, BCAT II, BCAT III, Middle

Tier, and Software Pathway programs, are delegated to a PEO by this instruction and

documented in the PEO assignment memorandum.

1.3.1.2.2. PEOs may delegate ACAT II, ACAT III, BCAT II, BCAT III, Middle Tier,

or Software Pathway programs MDA authorities to any individual and should delegate

to the lowest level. The SAE has the authority to rescind delegations. Delegations are

in writing (can be waived by SAE) and no further delegation is allowed.

1.3.1.2.3. PEOs will notify the SAE and SAF/AQX or SAF/SQX (for space programs),

of all MDA delegations and update applicable reporting systems (can be waived by

SAE).

14 DAFI63-101/20-101 16 FEBRUARY 2024

Table 1.1. MDA Delegation.

CATEGORIZATION

1

Designation

Authority

MDA

ACAT ID

DAE

DAE

ACAT IB

2

SAE

SAE

ACAT IC

DAE

SAE

Middle Tier meeting

MDAP criteria

SAE

3

SAE

Software Pathway

meeting MDAP criteria

SAE

4

SAE

4

or as delegated

ACAT II

5

SAE

PEO or as delegated to any

individual

ACAT III

5

SAE

PEO or as delegated to any

individual

BCAT I

SAE

SAE

BCAT II

SAE

PEO or as delegated to any

individual

BCAT III

SAE

PEO or as delegated to any

individual

MTA or software not meeting

MDAP criteria

SAE

PEO or as delegated to any

individual

Notes: 1) Refer to pathway publications for category descriptions.

2) SAE designated the MDA for all MDAP programs entering Milestone A after

October 1, 2016, unless the Secretary of Defense designates an alternate MDA

(reference Section 825 of Public Law 114–92 and paragraph 3.9).

3) Use of MTA for MDAP level requires pre-approval from DAE. (Reference

DoDI 5000.80)

4) Unless designated Special Interest by the DAE.

5) Includes ACAT programs in the MCA and UCA pathways.

1.3.2. Program Executive Officer. The PEO is responsible for and has authority to accomplish

assigned portfolio objectives and ensures collaboration across the integrated life cycle

management framework. The PEO identifies a Director of Engineering to be accountable to

the PEO for oversight of the portfolio’s engineering functional support. (T-2)

1.3.2.1. The PEO provides dedicated executive program management of delegated

programs. (T-1)

DAFI63-101/20-101 16 FEBRUARY 2024 15

1.3.2.2. All personnel assigned as a PEO meet the Key Leadership Position qualifications

and tenure requirements identified in this instruction and AFI 36-1301, Management of

Acquisition Key Leadership Positions. (T-0)

1.3.3. Program Manager (PM). The PM is the designated individual with the responsibility

for and authority to accomplish program objectives for development, production, and

sustainment to meet the user’s operational needs throughout life cycle of the program.

1.3.3.1. All programs on the AML, to include programs using MCA Pathway (i.e.,

ACATs), MTA Pathway, UCA Pathway, DBS Pathway (BCATs), or Software Acquisition

(SWA) Pathway, and weapons systems identified by DAFPD 10-9, Lead Command/Lead

Agent Designation and Responsibilities for United States Air Force Weapons Systems,

Non-Weapon Systems, and Activities, will have only one clearly identified and documented

PM. (T-0) A waiver is required to be submitted to the SAE if no single PM is identified.

1.3.4. Program Support Personnel. The PM leads the program organization in executing the

mission. Functional representatives within the program, irrespective of location or whether

supporting the program on a full or part time basis, take program direction from the PM for

program-related activities. The PM identifies and defines the roles and responsibilities of

support functions critical to the successful execution of the PM’s responsibilities. As a

minimum, the PM identifies and defines the Chief Engineer, the Product Support Manager

(PSM), the Chief Developmental Tester (Test Manager), and the Acquisition Intelligence

Analyst. The PM also identifies the Procuring Contracting Officer (PCO). Roles and

responsibility descriptions include specific delegations and limitations of delegations, establish

clear lines of accountability, and identify requirements for cross-functional management and

coordination. The PM keeps these descriptions current throughout the life cycle. (T-3) Other

functional positions should be identified; full descriptions are included at the PM’s discretion.

1.3.4.1. Chief Engineer. The Chief Engineer is identified as soon as possible following

the assignment of the PM. Note: The DAF term “Chief Engineer” is synonymous with the

DoDI 5000.88 term “Lead Systems Engineer.”

1.3.4.2. Product Support Manager. The PEO ensures a PSM is assigned to all ACAT I

and II programs, MTA programs, and weapon systems identified by DAFPD 10-9. (T-0)

For ACAT I and II programs in the operation and sustainment phase, all ACAT III, and

MTA programs, the PM and PSM may be dual-hatted if approved by the implementing

command and the PEO. For Joint MDAPs where the PSM is not a DAF position, a DAF

Service PSM position is established to support the MDAP PSM. The Service PSM reports

directly to the DAF organization assigned responsibility for supporting the Joint Program

Office. The PSM is assigned concurrently with the PM. (T-1)

1.3.4.3. Chief Developmental Tester (or Test Manager). All MDAPs require a Chief

Developmental Tester, which is designated as a Key Leadership Position in accordance

with AFI 36-1301. A Test Manager is identified for all other ACAT programs. While the

Test Manager does not need to meet the more stringent workforce qualifications of the

Chief Developmental Tester, the Test Manager must be able to perform the Chief

Developmental Tester or Test Manager responsibilities as detailed in DoDI 5000.89_DAFI

99-103, Capabilities-Based Test and Evaluation. (T-1)

16 DAFI63-101/20-101 16 FEBRUARY 2024

1.3.4.4. Acquisition Intelligence Analyst. Acquisition Intelligence Analysts are program

level intelligence representatives. The Acquisition Intelligence Analyst provides advice

and counsel on intelligence, surveillance, and reconnaissance (ISR) matters and assists the

program in being fully threat informed with authoritative intelligence. The Acquisition

Intelligence Analyst ensures that intelligence information is tailored for the program and

follows guidance described in DoDI 5000.86 as well as published Intelligence Community

(National, Agency and DAF) Directives and Instructions. (T-0)

1.3.4.5. Procuring Contracting Officer. The PCO is warranted by their respective agencies

to issue legal contracts between the U.S. Government and the contractor entity. All

programmatic, technical, and other contractual requirements established by the PM for the

contractor (or proposed contractor) must be issued by the PCO.

1.3.4.6. Other Program Support. Other program support consists of resources performing

program execution activities. This includes, but is not limited to, financial management,

cost analysis, administrative contracting officer, legal, program integration, cybersecurity

(including the Authorization Official), Environment, Safety and Occupational Health

(ESOH), mission assurance, small business, program protection, security, meteorological

analysis, other engineering specialties, and other logistics support.

1.3.5. Staff Organizations. Councils, committees, advisory groups, panels and staffs at all

levels provide advice and recommendations to the PM, PEO, MDA, SAE, and DAE who are

accountable for the overall program results. The PM is responsible for and has the authority

to execute a program. Staff organizations support the PM by providing trained personnel and

advice to the PM to maximize the opportunity to successfully execute the program. Staff

organizations provide objective inputs, such as legal or engineering, to the program decision

process. Staff organizations cannot exercise or imply decision-making authority on

programmatic matters unless explicitly delegated.

1.4. Waiver Authority (Tiering) and Tailoring. Tailoring is the ability to integrate, consolidate,

incorporate, and streamline documentation to meet the intent of the requirement in the most

efficient and effective manner possible. Waiving a requirement (e.g., statute, policy, document,

etc.) is different than tailoring. Waiving a document is stating that the document does not apply,

and the intent will not be fulfilled.

1.4.1. Waivers. A waiver is a statement to relinquish or provide exceptions to a specific

requirement.

1.4.1.1. The authorities to waive Wing or unit level requirements that are outside of the

acquisition execution chain in this publication are identified with a tier (“T-0, T-1, T-2,

T-3”) number following the compliance statement. See DAF Manual (DAFMAN) 90-161,

Publishing Processes and Procedures, for a description of the authorities associated with

the tier numbers. Submit requests for waivers for tiered requirements through the chain of

command to the appropriate tier waiver approval authority, or alternately, to the requestor’s

commander for non-tiered, non-acquisition execution compliance items.

1.4.1.2. Mandates to the acquisition execution chain defined in this DAFI, including

mandates to the PEO, MDA or other DA, PM, or other program office members, are not

elevated through the organizational chain of authority; therefore, tiering in accordance with

DAFI63-101/20-101 16 FEBRUARY 2024 17

DAFI 90-160, is not applied and the waiver authority is as specified or if not specified, to

the requestor’s DA.

1.4.1.3. Approval authority for this DAFI is the Assistant Secretary of the Air Force

(Acquisition, Technology, and Logistics) (SAF/AQ). Signature authority for waivers to

this DAFI is delegated to SAF/AQX; SAF/AQX will coordinate with SAF/SQX for

waivers impacting USSF or space programs. If there is a clear conflict between an

approved course of action and a DAF publication requirement, submit a DAF Form 679,

Department of the Air Force Publication Compliance Item Waiver Request/Approval, to

the publication office of primary responsibility (OPR) to obtain a waiver to requirements

or initiate changes to resolve the conflict. Conflicts are resolved by the appropriate

Headquarters Air Force (HAF) functional.

1.4.1.4. If there is a clear conflict between an approved course of action and a DoD level

issuance that cannot be addressed through tailoring, SAF/AQ will request waivers from the

appropriate DoD office regardless of the program’s categorization. USSF organizations

will route proposed waivers through SAF/SQX who will facilitate coordination with

SAF/AQ. If a waiver is required, the waiver request should be submitted to the OPR of

the DAF publication implementing the DoD issuance for appropriate staffing and approval.

If the waiver requests cannot be resolved between SAF/AQX and SAF/SQX adjudication

processes, the requests will be resolved by SAF/AQ and SAF/SQ.

1.4.1.5. Waivers for SAPs are submitted through the relevant Major Commands and Field

Commands (MAJCOM/FLDCOM) SAP management office, as designated in accordance

with AFPD 16-7for submission to SAF/AAZ for adjudication.

1.4.2. Tailoring. Tailoring recognizes that acquisition programs are not all the same. Policy

permits customized reviews, processes, and decision support information to accommodate the

unique characteristics of a program while still meeting the statutory and regulatory needs for

decision making and oversight. Tailoring ensures a program or project can balance all types

of risks, including technical, programmatic, or strategic risks in providing the needed capability

to the warfighter or user in the shortest time while ensuring affordability, supportability, system

safety and performance. Tailoring for programs is requested by the PM and approved by the

MDA or DA. This is done to make better decisions by using a systematic risk-informed

decision approach based on sufficient, relevant, and timely information. Note: Reference

DoDI 5000.02 and DAFPAM 63-128, Integrated Life Cycle Management, for more

information on tailoring.

1.4.2.1. Tailoring is documented, including the supporting rationale and citation to the

applicable statute or regulation. The PM identifies the tailoring strategy in the Acquisition

Strategy or Acquisition Decision Memorandum (ADM) (documenting the tailoring

strategy can be waived by the DA). The DA approves the tailoring strategy as part of the

documentation approval.

1.4.2.2. Tailoring may be limited by statute or other guidance and should not result in a

requirement being waived, except as specified by statute.

1.5. PEO Portfolio Assignment or Transfer.

1.5.1. PEO Portfolio Assignment. During the requirements validation process, the

requirements sponsor informs SAF/AQ or the Assistant Secretary for Space Acquisition and

18 DAFI63-101/20-101 16 FEBRUARY 2024

Integration (SAF/SQ) of the potential program. Information provided contains proposed

program description, estimated dollar value, funding status, warfighter need date, and

anticipated categorization level. With input from the implementing command, SAF/AQ or

SAF/SQ assigns the effort to a PEO and includes confirmation of proposed categorization level

and the MDA. The lead command or sponsor submits a request for PEO assignment once

funding is identified and the DAF budget and program requirements have been developed and

submitted to the appropriate requirements approval authority.

1.5.1.1. PEO assignment should be initiated for all programs projected to be on the AML

prior to conducting an acquisition life cycle decision to include program initiation or

contracting decision. Acquisition life cycle decisions can be made once the PEO has

received the candidate identification memo. If the PEO decides to proceed, there is no

need to wait until the official final memo is received. Exceptions: PEO assignment is not

required for modifications to current programs which are already assigned to a PEO. UCA

programs may have the acquisition authority designated outside the PEO assignment

process.

1.5.1.2. For existing systems or systems transitioning from another agency, the sponsor

provides the program description, estimated dollar value, and funding status to SAF/AQ or

SAF/SQ for assessment. Upon acceptance and with input from the implementing

command, SAF/AQ or SAF/SQ assigns the effort to a PEO and determines the MDA.

1.5.1.3. For technology demonstration projects that may transition into acquisition

programs or deployed capability, the sponsor may request SAF/AQ or SAF/SQ temporarily

assign a PEO to support technology demonstration transition planning. Temporary PEO

assignments are revalidated on an annual basis (may be waived by SAF/AQ or SAF/SQ)

and may be transitioned to a permanent assignment based on confirmation of a validated

requirements document in coordination with the implementing command.

1.5.2. PEO Portfolio Transfer. Coordinate transfer of programs between PEO portfolios

through the implementing command(s) for approval by the SAE. The impacted organizations

prepare a joint request providing rationale and justification for the proposed transfer (T-1).

Send PEO Portfolio Assignment requests to SAF/AQ or SAF/SQ.

1.5.3. Basing Actions. Basing actions include the activation, inactivation, or adjustment, that

result in the increase, decrease, or movement of DAF and non-DAF units, missions, manpower

authorizations, or weapon systems to DAF and non-DAF locations.

1.5.3.1. Depot actions that exceed the scope of Depot Source of Repair (DSOR) processes

may be considered basing actions.

1.5.3.2. In general, PEO portfolio assignment and transfer activities will not result in a

strategic basing action. However, for actions meeting the following criteria, the

implementing command, with support from the PM, will provide a summary of the action

to the Assistant Secretary of the Air Force for Installations, Environment and Energy

(SAF/IE) for review (may be waived by SAF/IE) and may require processing as a basing

action:

1.5.3.2.1. The movement of personnel across MAJCOM/FLDCOMs.

DAFI63-101/20-101 16 FEBRUARY 2024 19

1.5.3.2.2. Facility requirements with construction that require the use of Military

Construction (MILCON) funding or government leased space.

1.5.3.2.3. New work bringing 100 or more military or government personnel to a base.

1.5.3.2.4. Action may result in total installation growth greater than 1000 personnel,

including military, civilian, and contractor personnel.

1.5.3.2.5. Special interest or congressional actions regardless of size or scope.

1.5.3.2.6. Refer to AFI 10-503, Strategic Basing, for guidance on the basing process.

20 DAFI63-101/20-101 16 FEBRUARY 2024

Chapter 2

ROLES AND RESPONSIBILITIES

2.1. Purpose. This chapter defines roles and responsibilities and is not meant to be all inclusive;

additional complementary functional and organizational roles and the details to execute the roles

and responsibilities may be found throughout this document and other publications referenced in

Attachment 1. Responsibilities of headquarters staff are located in mission directives; the

responsibilities of SAF/AQ staff are included in HAF Mission Directive (MD) 1-10, Assistant

Secretary of the Air Force (Acquisition) and the responsibilities of SAF/SQ staff are included in

HAFMD 1-17, Assistant Secretary of the Air Force (Space Acquisition and Integration). Note:

Roles and responsibilities related to acquisition industrial preparedness are explained in Chapter

12.

2.2. Service Acquisition Executive. SAF/AQ is the SAE for DAF non-space programs. SAF/SQ

is the SAE for space programs. The SAE has overall authority for the management of DAF

acquisition programs. The SAE will:

2.2.1. Execute SAE responsibilities outlined in DoD guidance for execution of DAF

acquisitions. The SAE is responsible for the integrated life cycle management of systems and

Service programs from entry into the defense acquisition system to retirement and disposal.

This includes research, development, engineering, test, evaluation, production, delivery, and

sustainment of new systems, or modifications and support of existing systems.

2.2.2. Ensure programs, to include modifications, are properly defined and justified in budget

documentation.

2.2.3. Execute Title 10 USC Section 2464, Core Logistics Capabilities, and Title 10 USC

Section 2466, Limitations on the Performance of Depot-Level Maintenance of Materiel.

Ensure implementation across acquisition programs for compliance with Core and organic

requirements (T-0) Reference AFI 23-101, Materiel Management Policy, for additional

information.

2.2.4. Assign programs to PEOs.

2.3. Senior Procurement Executive (SPE). The DAF Senior Procurement Executive is the

Assistant Secretary for the Air Force for Acquisition Technology & Logistics (SAF/AQ). SAF/AQ

is designated as the single DAF SPE in accordance with 41 USC Section 1702(c). However, in

accordance with 10 USC Section 9016, Assistant Secretaries of the Air Force, as amended by

FY22 NDAA, SAF/SQ may discharge assigned duties and authorities of a SPE exclusively for

execution of space systems and programs as delegated by the Secretary of the Air Force (SECAF).

2.4. Milestone Decision Authority. The MDA may also be referred to as the DA. MDA will:

2.4.1. Maintain overall responsibility for a program.

2.4.2. Approve tailoring of program strategies, life cycle phases, and documentation of

program information as proposed by the PM. Tailor oversight, documentation, timing and

scope of decision reviews and decision levels to fit particular program conditions consistent

with applicable laws and regulation.

DAFI63-101/20-101 16 FEBRUARY 2024 21

2.4.3. Be accountable for program cost, schedule, risk, and performance reporting to higher

authority, including congressional reporting.

2.4.4. Ensure that when a program enters the acquisition system at a point other than pre-

Milestone A or equivalent, all phase-specific criteria relating to a skipped milestone or other

decision point are reviewed for applicability and completed as determined appropriate by the

MDA. Reference the AAF Documentation Identification (AAFDID) tool

(https://www.dau.edu/aafdid/Pages/about.aspx), pathway-specific guidance, and DoD

acquisition guides (https://aaf.dau.edu/aaf/policies/) for milestone criteria and

documentation requirements.

2.4.5. Comply with all program milestone certification requirements as prescribed by statute

or DoD policy.

2.4.6. Conduct program oversight to assess the adequacy of all life cycle execution strategies,

planning, model, documents, and approve the termination of an acquisition program.

2.5. Program Executive Officer. The PEO will:

2.5.1. Accomplish assigned portfolio or program objectives for development, production,

sustainment, and disposal of the assigned portfolio including assigned ACAT programs and

their modifications. The PEO interacts with other PEOs with similar program content or

contractor and business segments to identify shared concerns, opportunities for leverage, and

to develop an informed position of contractor performance within the portfolio at the

department, Service, PEO, and program level. The PEO will work with the lead command and

HAF Capability Director to secure necessary funding in time to meet portfolio or program

objectives.

2.5.2. Execute oversight of the assigned portfolio of programs, in some cases as the MDA,

while continuously assessing and optimizing programs within their portfolio. For programs

with significant programmatic issues, the PEO reviews the program for restructure or

termination. When necessary to support DAF priorities and missions, the PEO recommends

shifts in investments in the portfolio.

2.5.3. Maintain knowledge of prime and major subcontractor efforts within the portfolio and

engage periodically with industry counterparts to ensure transparency and unity of effort in

portfolio execution.

2.5.4. Notify the implementing command of new missions and changes to include proposed

program realignments. The PEO will work with the implementing command to identify need

for the government program office to include facilities, personnel, and resources and validate

infrastructure investment requirements identified by the PM.

2.5.5. Work closely with the relevant laboratories, implementing commands, and the

Technology Executive Officer to maintain cognizance of and leverage pertinent science and

technology activities and advancements to develop and execute capability development

pipelines within their portfolio.

2.5.6. Ensure programs within their portfolio receive appropriate support to include

acquisition intelligence, security, facilities, and other resources in collaboration with the

implementing command.

22 DAFI63-101/20-101 16 FEBRUARY 2024

2.5.7. Determine if modifications in their portfolio will be designated as new acquisition

programs.

2.6. Program Manager (PM). The PM will:

2.6.1. Be accountable for assigned programs through the acquisition execution chain of

authority on all matters of program cost, schedule, risk, performance, and asset disposal.

2.6.2. Be responsible for program execution, sponsor, or user support with development of

capability requirements, and deliver systems that meet documented user requirements while

seeking to minimize costs and improve readiness throughout the life cycle.

2.6.3. Implement Digital Materiel Management in assigned programs, including integrated

digital environments, where appropriate, leveraging enterprise DAF Digital tools to deliver

improved program outcomes.

2.6.4. Make a national security system (NSS) determination as outlined in Attachment 4 and

for performing annual reviews for changes in determination status.

2.6.5. Ensure compliance with all applicable regulatory and statutory guidance to include

developing and maintaining appropriate programmatic documentation and relevant available

or required model data.

2.6.6. Develop tailored and executable program strategies, models, and documentation,

appropriate for program risk and approved by the MDA.

2.6.7. Propose waivers and deviations as needed to streamline, tailor, and execute the assigned

program.

2.6.8. Ensure systems and end items meet the warfighter's sustainment and capability needs

based on an accurate Authoritative Source of Truth, which captures the current state and the

history of the technical baseline. It serves as the central reference point for models and data

across the life cycle. The authoritative source of truth will provide traceability as the system

of interest evolves, capturing historical knowledge, and connecting authoritative versions of

the models and data, reference AFI 90-7001 for additional guidance.

2.6.9. Design, build, test, and continuously update systems to consider evolving adversary

threats and address acquisition security considerations in accordance with Chapter 6,

acquisition security considerations.

2.6.10. Comply with PM responsibilities outlined in AFI 17-101, Risk Management

Framework (RMF) for Air Force Information Technology (IT).

2.6.11. Identify infrastructure and supporting requirements to the appropriate

MAJCOM/FLDCOM. Coordinate DAF plant expansion or construction efforts per Chapter

12 of this DAFI.

2.6.12. Utilize Product Groups, Modular Open Systems Architectures (MOSA) and enterprise

management of materiel, including IT infrastructure, to minimize the proliferation of system-

unique equipment when appropriate to improve interoperability, decrease costs, or for

operational and sustainment considerations. Review available and projected Enterprise IT

services for applicability to the system program (to include all components such as the prime

item, support equipment, training and simulation equipment, embedded software, and software

development environments) and leverage EIT to the maximum possible extent.

DAFI63-101/20-101 16 FEBRUARY 2024 23

2.6.13. Identify requirements and the risk associated with unmet requirements for the

government program office to include facilities, personnel, and resources and provide them to

the PEO, or designee, to work with the appropriate implementing command.

2.6.14. Coordinate and receive approval from the Air Force Life Cycle Management

Center/Cryptologic and Cyber Systems Division (AFLCMC/HNC [contact AF COMSEC CCI

Communications Security/Controlled Cryptographic Item (COMSEC/CCI) development,

acquisition, modernization, sustainment, disposal, or action affecting controlled cryptographic

item inventory balances. Program offices are not authorized to bypass centralized procurement

of controlled cryptographic item without approval of AFLCMC/HNC or the Chief Information

Officer (SAF/CN).

2.6.15. Identify and satisfy external certifications, reviews, and approvals applicable to the

system.

2.6.16. Ensure all appropriate program protection activities are completed and requirements

are met, reference DoDI 5000.83_DAFI 63-113 for additional guidance.

2.6.17. Ensure all appropriate financial audit responsibilities are met, including establishing

controls and retaining documentation, to ensure accountability of assets and preparation of

accurate financial statements.

2.7. Product Support Manager. The PSM takes program direction from the PM and will:

2.7.1. Be accountable for all product support matters regarding program cost, schedule,

performance, compliance, and supportability. Additionally, the PSM ensures the program’s

product support strategy incorporates logistics, mishap, intelligence supportability and ESOH

risk data; integrated product support elements and aligns to overarching DAF enterprise

priorities.

2.7.2. Be accountable for leading program office integrated product support throughout the

system life cycle.

2.7.3. Be accountable for any formal delegation of program management authority and

assignment of programmatic responsibilities by the PM.

2.7.4. Continually assess reliability and maintainability of the weapon system and its

subcomponents throughout its life cycle.

2.8. Chief Engineer. The Chief Engineer takes program direction from the PM and will:

2.8.1. Develop and implement a comprehensive systems engineering strategy addressing the

total life cycle of the system and documents the strategy.

2.8.2. Be accountable for leading program office engineering execution throughout the system

life cycle in accordance with:

2.8.2.1. Chapter 5 , Systems Engineering.

2.8.2.2. Engineering program management and programmatic authorities formally

delegated or assigned by the PM.

2.8.2.3. Engineering or technical authorities assigned or delegated to the Chief Engineer

by specific certification authorities or DAF policy.

24 DAFI63-101/20-101 16 FEBRUARY 2024

2.8.3. Serve as the overall Engineering and Technical Authority for the program office.

2.8.3.1. While Chief Engineers do not make final programmatic decisions, they do make

objective engineering and technical decisions that both affect and inform programmatic

decisions.

2.8.3.2. Examples of these engineering and technical decisions include, but are not limited

to, the following:

2.8.3.2.1. Identify and assess program technical risks and recommend to the PM

proposed mitigation measures.

2.8.3.2.2. Assess and approve engineering changes and make implementation

recommendations to the PM including but not limited to determining existence of

Critical Program Information.

2.8.3.2.3. The Chief Engineer ensures the delivered product design data satisfies

Technical Data Package and Model-based Technical Data Package requirements and

define the program’s Authoritative Source of Truth.

2.8.3.2.4. DAFPAM 63-128, provides more information on engineering and technical

authority, both within a program office and in organizations providing external support

to program offices.

2.8.3.2.5. AFPAM 63-129, provides information and recommended procedures for

implementing engineering development and sustainment processes and procedures for

the procurement of air systems.

2.8.3.2.6. DoDI 5000.83_DAFI 63-113 provides guidance on protection planning

activities for the integrated management of system security and threat risks by applying

system security engineering best practices and processes.

2.9. Chief Developmental Tester (Test Manager). The Chief Developmental Tester (or Test

Manager for non-MDAPs) takes program direction from the PM and will:

2.9.1. Coordinate the planning, management, and oversight of Developmental Test and

Evaluation (DT&E) activities. See DoDI 5000.89_DAFI 99-103 for more detailed information

on Chief Developmental Tester or Test Manager requirements and responsibilities.

2.9.2. Maintain oversight of program contractor, government, and other program-related

DT&E activities. Coordinate with the Operational Test Organization to establish integrated

testing where feasible and practicable.

2.9.3. Advise the PM on all DT&E activities including contractor testing and help PM make

technically informed, objective judgements regarding DT&E results.

2.9.4. Co-chair and provide program guidance to the Integrated Test Team, a cross- functional

team responsible for developing the program T&E strategy.

2.10. Acquisition Intelligence Analyst. Takes direction from the PM and will:

2.10.1. Provide intelligence and ISR subject matter expertise to the acquisition effort. Areas

of expertise include but are not limited to: Critical Intelligence Parameter (CIP) identification

and associated threat forecasts; tailored threat reporting (e.g., briefing, planning, risk analysis,

etc.) to include validated on-line life cycle threat activities; identification of relevant threat

DAFI63-101/20-101 16 FEBRUARY 2024 25

models, data, and cross-program ISR dependencies; management of intelligence production

requirements (PRs) and intelligence collection requirements (CRs).

2.10.2. Manage intelligence supportability planning, to include an Intelligence Sensitivity

Determination (ISD) process for supported leadership, Intelligence Supportability Analysis

(ISA), as appropriate, and document intelligence support requirements.

2.10.3. Provide Intelligence Health Assessments (IHAs), as appropriate.

2.10.4. Assist in obtaining relevant threat support for program protection planning, critical

program information identification, anti-tamper measures, and Supply Chain Risk

Management (SCRM).

2.10.5. Partner with PMs to ensure risk associated with intelligence-sensitive programs are

considered as part of a program’s overall risk assessment that align with program timelines.

2.11. Implementing Commanders. Implementing commanders which include Commander AF

Materiel Command (AFMC/CC) and Commander, Space Systems Command (SSC) or delegate,

will:

2.11.1. Provide the SAE, PEOs, and PMs support capabilities to facilitate execution of the

acquisition execution chain of authority. This includes technical assistance, infrastructure,

modeling and simulation, test capabilities, laboratory support, professional education, training

and development, management tools, human resources, and all other aspects of support.

2.11.2. Provide pertinent science and technology activity information to PEOs about

technological advancements from DoD laboratories which could be leveraged to support

program objectives.

2.11.3. Provide the Chief of Staff of the United States Air Force (CSAF), Chief of Space

Operations of the USSF (CSO), SAE, PEO, and MAJCOM/FLDCOM commanders support

for requirements formulation and phasing, continuous capability and technology planning, and

development of acquisition and life cycle sustainment strategies.

2.11.4. Support all domestic, international, and security cooperation (including FMS)

programs in which the DAF participates in accordance with a signed agreement.

2.11.5. Ensure timely and accurate intelligence analysis, information, and support is provided

to and integrated into the acquisition process; this includes designating an intelligence focal

point. Ensure the identification and documentation of derived intelligence requirements for

intelligence products and services, and assessment of intelligence-related risk during all phases

of the life cycle. Integrate intelligence supportability analysis into all life cycle models and

programming.

2.11.6. Develop processes and procedures for accurate collection and reporting of 10 USC

Section 2464 and 10 USC Section 2466 information. Maintain depot maintenance workload

mix database and analysis products.

2.11.7. Collaborate with lead commands and PMs. Collect, validate, and maintain current

requirements, priorities, and funding data by system for all elements of depot activation and

report data to Headquarters DAF upon request. Establish a central repository for depot

activation requirements data, to include associated rationale and impacts.

26 DAFI63-101/20-101 16 FEBRUARY 2024

2.11.8. Conduct planning to support requirements and capability development activities and

decisions.

2.11.9. Charter and appoint Product Group Managers when enterprise management of

materiel used to support multiple weapon systems is desired to improve interoperability and

decrease costs through commonality.

2.11.10. Nominate a MAJCOM/FLDCOM Competition and Commercial Advocate and

Alternate (reference Air Force Federal Acquisition Regulation Supplement (AFFARS),

Mandatory Procedure (MP) 5306.502).

2.11.11. Collect combat damage data with the purpose of enhancing survivability, reducing

casualties, and increasing operational readiness in support of Joint Air Combat Damage

Reporting.

2.12. Authorizing Official (AO). The appointed AO formally assumes responsibility for

operating Information Systems and Platform Information Technology (PIT) systems at an

acceptable level of risk.

2.12.1. DoD Information Systems and Platform Information Technology systems are not

permitted to operate on or connect to any internal or external network without AO approval.

2.12.2. Each SAF Chief Information Officer (CIO) appointed AO makes specific decisions

for systems under their purview in accordance with DoDI 8510.01, Risk Management

Framework (RMF) for DoD Information Technology; AFI 17-101 and AFI 17-130,

Cybersecurity Program Management.

2.12.3. The AO appointed by the A2/6 as Head of the United States Air Force (USAF)

intelligence community element accredits and makes associated risk management decisions

for all USAF Sensitive Compartmented Information (SCI) assets and data; ISR mission assets

and data (regardless of classification) under Intelligence Directive 503, Intelligence

Community Information Technology Systems Security Risk Management, Certification, and

Accreditation. An SCI asset includes all/any system, subsystem, component, etc., that

accesses, uses, processes or stores SCI data, as defined by ICD 703, Protection of Classified

National Intelligence, Including Sensitive Compartmented Information.

2.13. Operational Command, Direct Reporting Unit (DRU), and Field Operating Agency

(FOA) Commanders. Operational Commands (“lead command” or “using command”), FOAs

Commanders, Space Operations Command, Space Systems Command, and Space Training and

Readiness Command (STARCOM) or delegate will:

2.13.1. Develop and document capability-based requirements and accomplish analysis to